85

6 Modifications to the basic vehicle

6.6 Frame modifications

MITSUBISHI FUSO body/equipment mounting directives for FE Issue date: 20. 10. 2020

! Only print out complete sections from the current version

6.6 Frame modifications

• The maximum permissible axle loads must not be exceeded, while the minimum front axle load must be

exceeded.

• Rear underride guard: fastened in the same way as on a standard vehicle.

• Extend the mounting frame to the end of the frame.

6.6.1 Precautions for modification

In the case that a rear body of special design is mounted or the vehicle is to be used in special conditions, use

utmost care that neither the structure nor the strength of the frame is impaired during mounting or modification

work.

When mounting a rear body of special design, pay full attention to even weight distribution on the frame.

Refer to "10.5.2 Frame section modulus" É 10.5.2.

Attaching stiffeners, drilling holes or welding objects to the frame can affect the strength of the frame greatly,

possibly resulting in a deformed or cracked frame. Avoid performing any unnecessary reinforcement, drilling or

welding work on the frame.

6.6.2 Extending and shortening

• Frame rear overhang extending procedure

Perform the following steps to extend the frame rear overhang.

• Extension members

As high tensile strength steel (540 MPa class) hardens more easily at welds than automotive structural

steel (MJSH440), follow the instructions below.

(a) Be sure to use a low-hydrogen type electrode. Especially, where the weld must have the same strength

level as the base metal, use a low hydrogen, high tensile strength type electrode.

(b) Short weld beads are more likely to crack due to low hardening rate, so in areas requiring many short weld

beads, perform continuous welding instead.

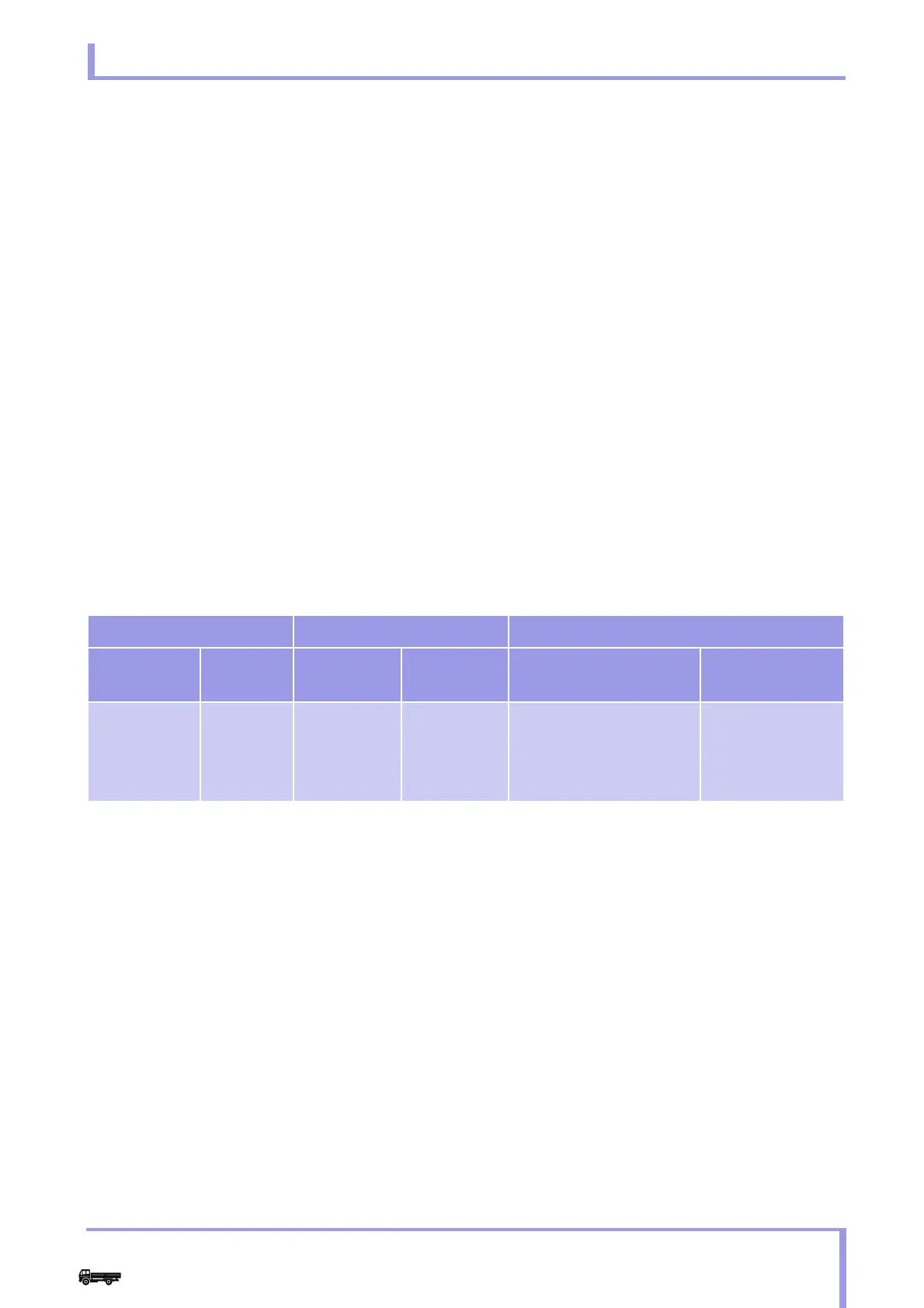

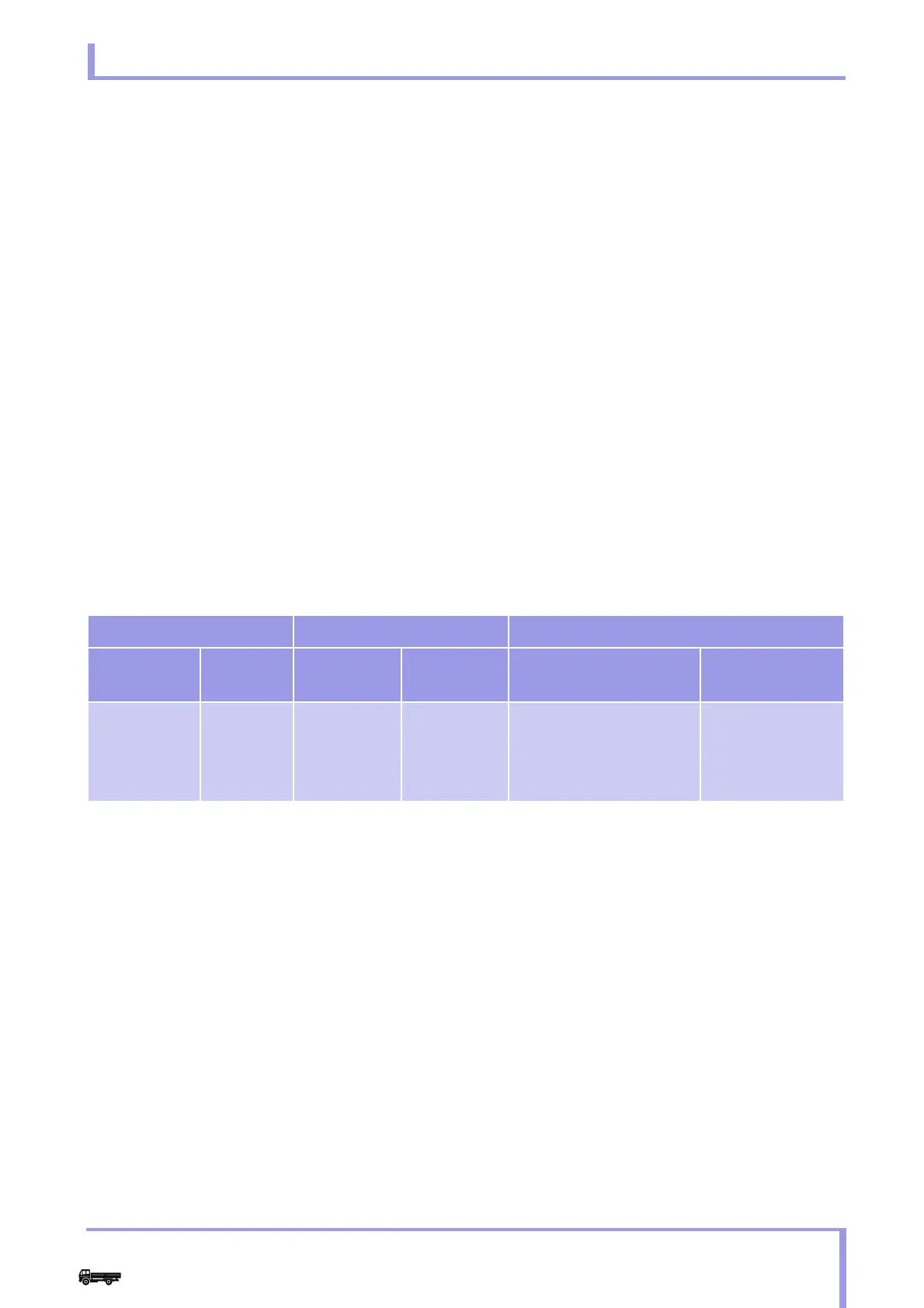

Extension member Reinforcement Electrode

Material Thickness Material Thickness

Shielded metal arc

welding

CO

2

gas shielded

arc welding

MJSH440

(S355J2C+N)

HTP540

(S500MC)

Same as

the side

rail

MJSH440

(S355J2C+N)

3.2 - 4.5 mm

Illuminite base, for

540 MPa, D4301 or

equivalent as per JIS

Z3211

YGW11 or

equivalent as per

JIS Z3312

Loading...

Loading...