89

6 Modifications to the basic vehicle

6.7 Mounting of implements and auxiliary components

MITSUBISHI FUSO body/equipment mounting directives for FE Issue date: 20. 10. 2020

! Only print out complete sections from the current version

6.7.2 Wheel chocks

Mounting

• In a suitable bracket so that they cannot rattle.

• Secured to prevent loss.

• Ensure good accessibility.

6.7.3 Spare tire carrier

• Install under the frame, on the side of the frame or

on the body in accordance with the chassis

drawing.

• It must be easily accessible and easy to handle.

• The Spare tire - carrier

When remodelling the tire carrier, followings must

be paid attention:

(a) A single worker can easily remove or attach the

tire.

(b) Interference is not caused with parts other than

the intended stopper when tightening the tire

on the tire carrier.

(c) The worker can attach even burst tires.

(d) The tightening section is prevented from

becoming loose.

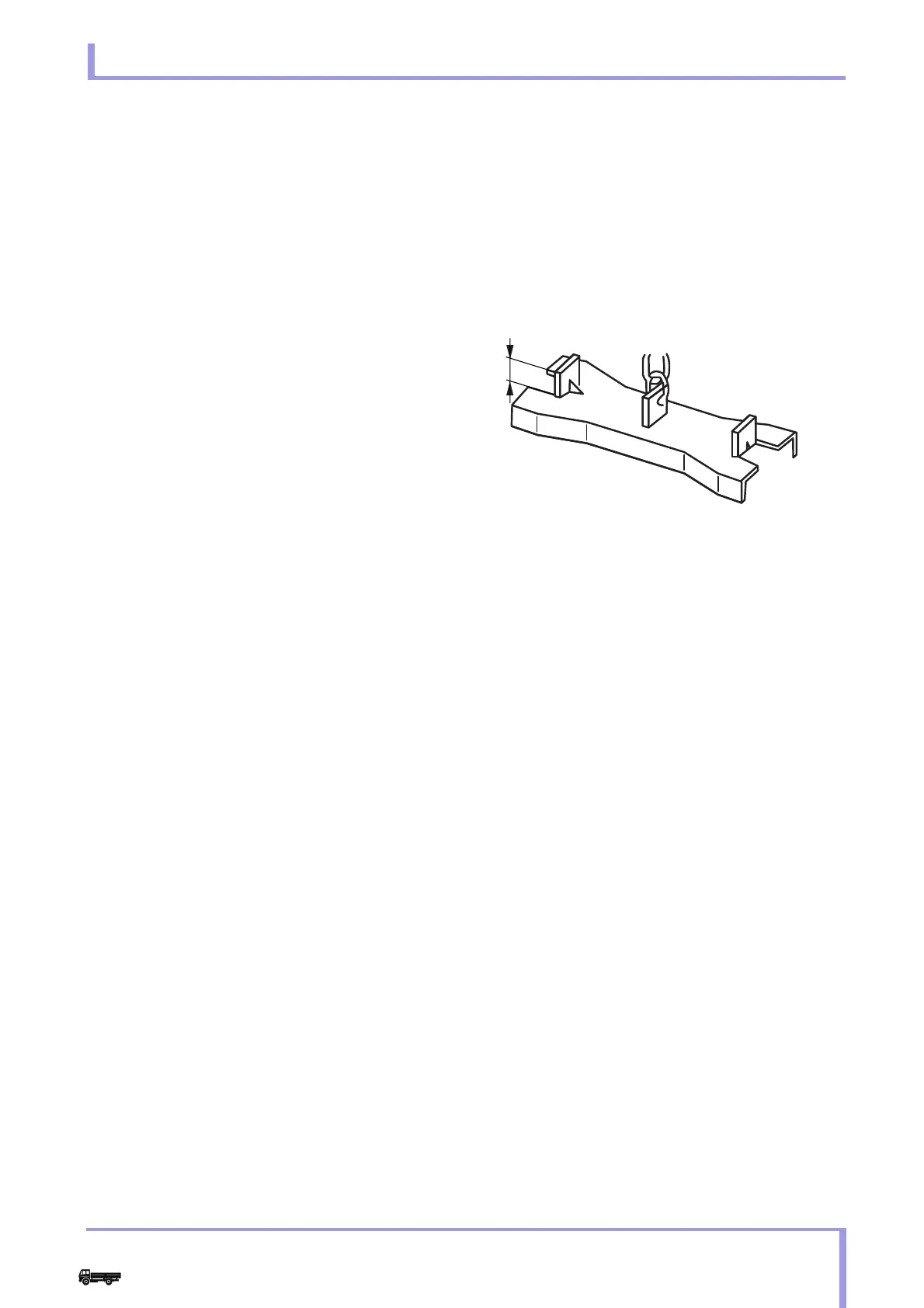

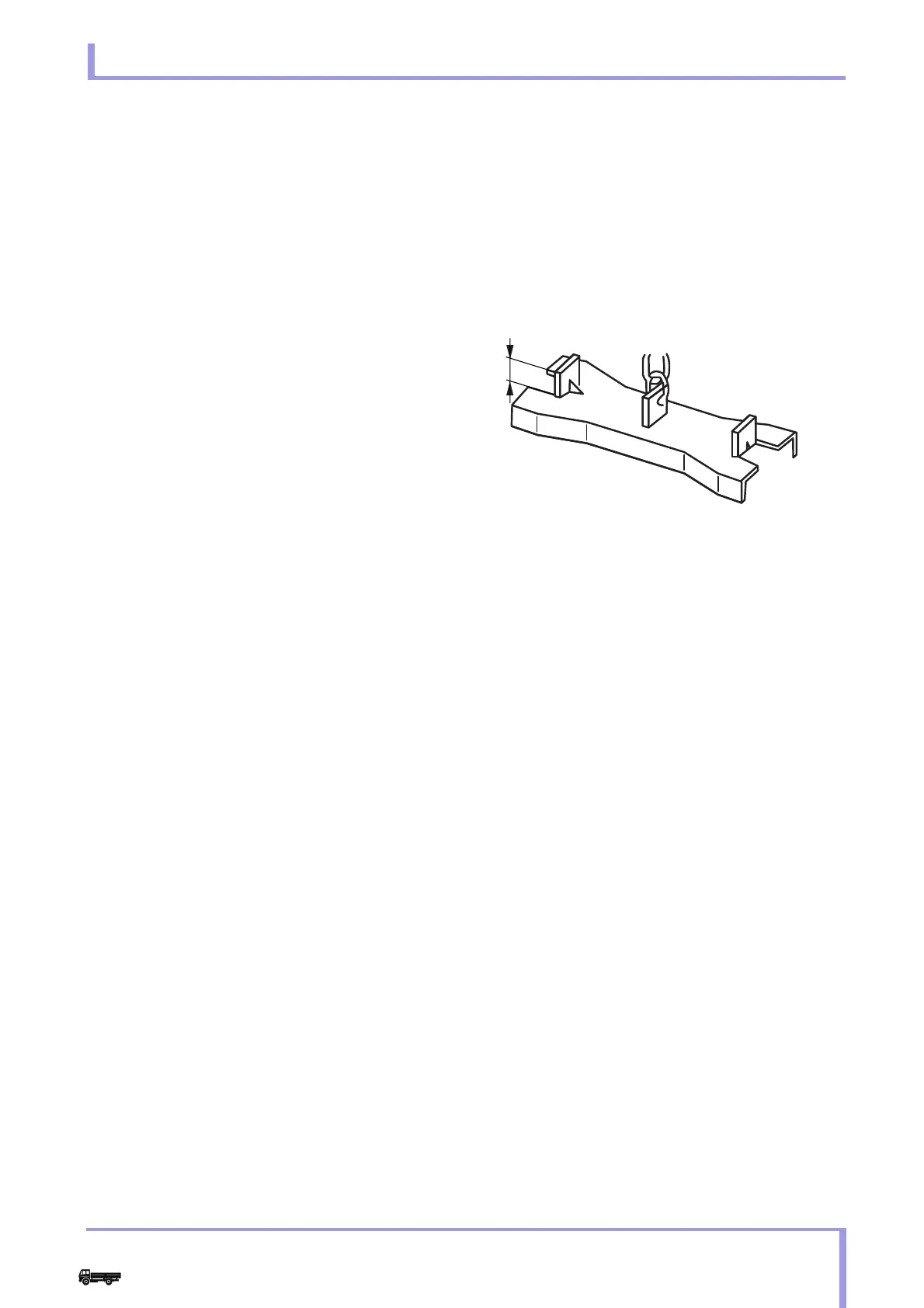

Example 1: Clamped tire-carrier

• The tightening bolt must be 30 mm or

longer.

• Double nuts must be used for tightening.

• The structure having a height difference for

preventing falling on the bracket.

• The structure having a stopper for

preventing tightening nuts and bolts from

falling.

Example 2: Hoisted tire-carrier

• The structure must have a spring inserted

below the hoisting plate.

• The structure must prevent reverse rotation

of the hoisting shaft.

• The structure must have a lock for

preventing the tire from falling

(e) The tightening bolt must be M10, 7 T strength

or an equivalent product. (clamped tire-carriers)

(f) The tire shape must limit movement in the

forward, backward, left and right directions.

(clamped tire-carriers)

(g) Take care to prevent injury when hoisting tires.

(hoisted tire-carriers)

(h) Tightening bolts must be tightened to a torque

of at least 49 Nm and by a force at least 290 N

at handles. The tire-carrier must be designed to

have enough contact area to support the tire

securely. (hoisted tire-carriers)

(i) The height difference on the lifter must be at

least 10 mm, or the lifter must be of a shape

that enables the same effect. (hoisted tire-

carriers)

(j) When manufacturing the carrier, apply a tensile

load of 4900 N or more on the lifter. (hoisted

tire-carriers)

(k) Affix a Caution Plate indicating the

recommended tightening torque 49 Nm at a

position that can be easily seen during

operation.

Loading...

Loading...