CHAPTER 5: SETTINGS CONTROL ELEMENTS

C70 CAPACITOR BANK PROTECTION AND CONTROL SYSTEM – INSTRUCTION MANUAL 5-291

5

When current is less than the dropout level, I

n

> 0.97 × k × I

B

, the element starts decreasing the thermal energy:

Eq. 5-27

where

∆t is the power cycle duration

n is the power cycle index

t

op(In)

is the trip time calculated at index n as per the IEC255-8 cold curve or hot curve equations

t

rst(In)

is the reset time calculated at index n as per the reset time equation

I

n

is the measured overload RMS current at index n

E

n

is the accumulated energy at index n

E

n–1

is the accumulated energy at index n – 1

The thermal overload protection element removes the

THERMAL PROT 1 OP output operand when E < 0.05. In case of

emergency, the thermal memory and

THERMAL PROT 1 OP output operand can be reset using THERM PROT 1 RESET setting.

All calculations are performed per phase. If the accumulated energy reaches value 1 in any phase, the thermal overload

protection element operates and only resets when energy is less than 0.05 in all three phases.

Table 5-38: Typical time constants

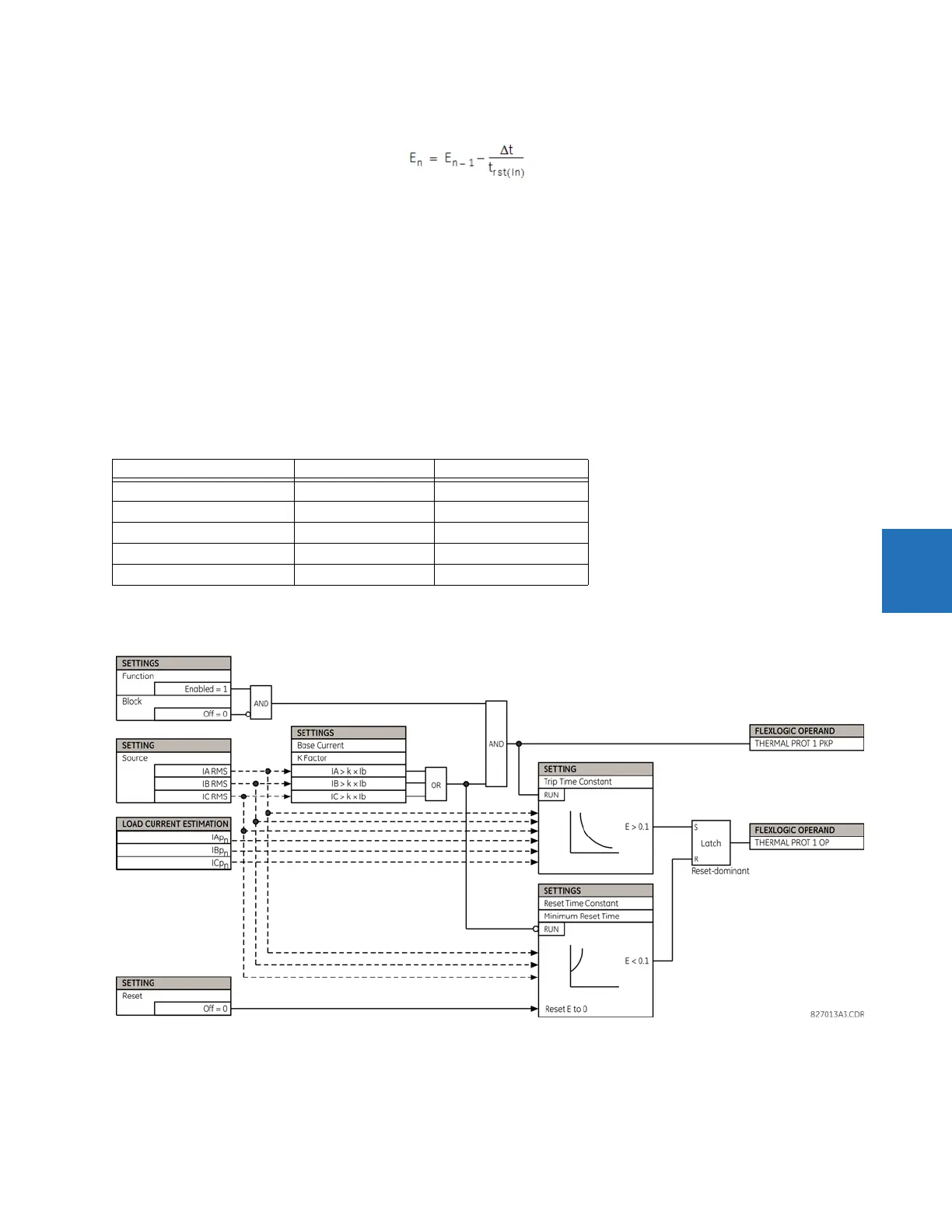

The figure shows the logic for the thermal overload protection element.

Figure 5-160: Thermal overload protection logic

Protected equipment Time constant Minimum reset time

Capacitor bank 10 minutes 30 minutes

Overhead line 10 minutes 20 minutes

Air-core reactor 40 minutes 30 minutes

Busbar 60 minutes 20 minutes

Underground cable 20 to 60 minutes 60 minutes

Loading...

Loading...