Setup/Startup

10 3A3393C Operation

Setup/Startup

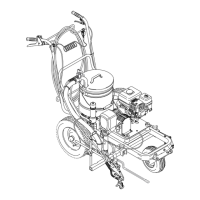

1. Perform

Pressure Relief Procedure

, page 9.

2. Perform Grounding Procedure (For Flammable

Flushing Fluids Only), page 9 if using flammable

materials.

3. Fill throat packing nut with Throat Seal Liquid (TSL)

to decrease packing wear.

4. Check engine oil level. Add SAE 10W-30 (summer)

or 5W-30 (winter). See engine manual.

5. Fill fuel tank.

6. Set pump valve(s) to OFF (250

SPS has one pump

valve; 250

DC has two pump valves).

7. If removed, install strainer(s).

8. Turn prime valve(s) down (250

SPS has one prime

valve; 250

DC has two prime valves). Turn pressure

control counterclockwise to lowest pressure.

NOTE: Minimum hose size allowable for proper

sprayer operation is 3/8 in. x 11 ft (9.5mm x 3.3m).

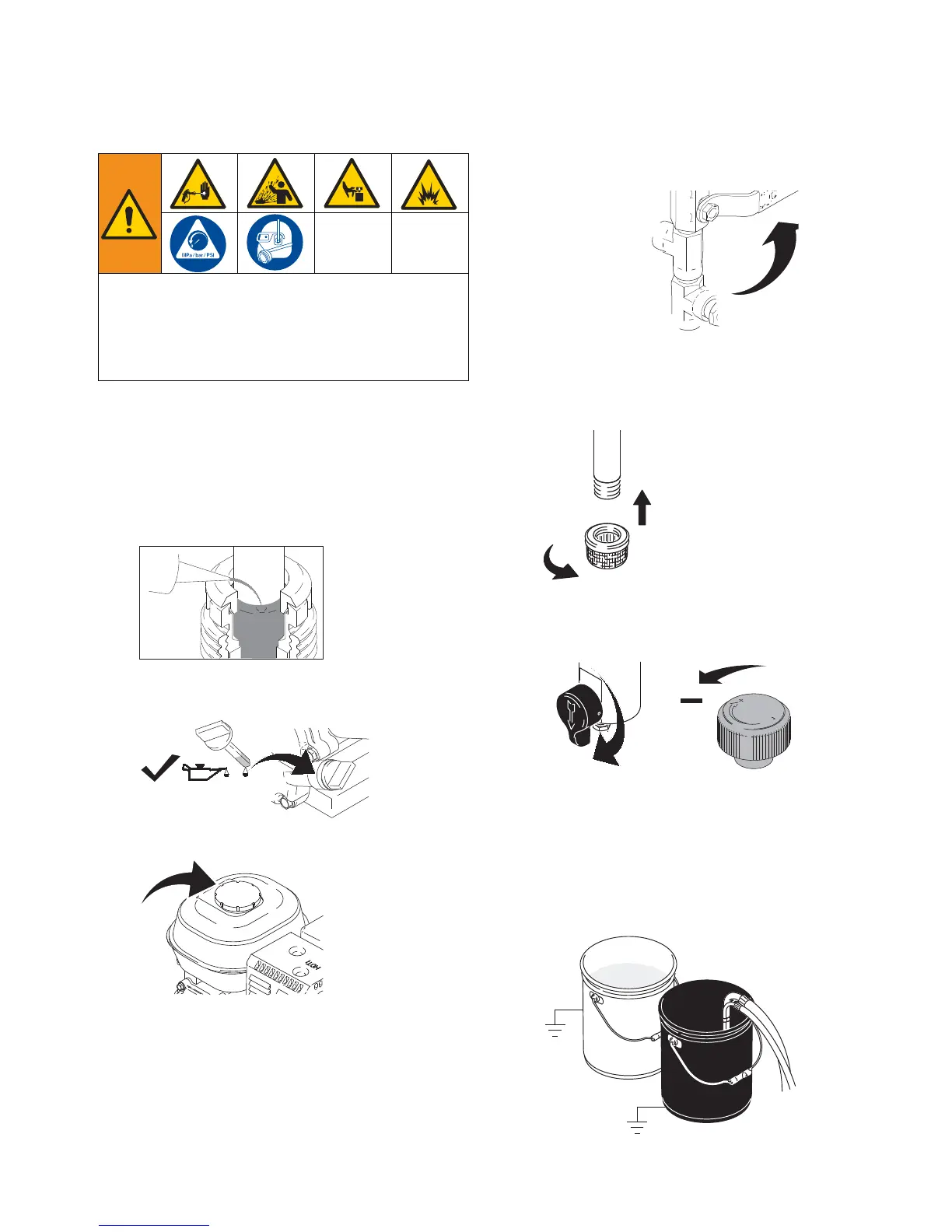

9. Place siphon tube set(s) in grounded metal pail par-

tially filled with flushing fluid. Attach ground wire to

true earth ground. Use water to flush water-base

paint and mineral spirits to flush oil-base paint and

storage oil.

This equipment stays pressurized until pressure is

manually relieved. To help prevent serious injury

from pressurized fluid, such as skin injection, splash-

ing fluid and moving parts, follow the Pressure Relief

Procedure when you stop spraying and before clean-

ing, checking, or servicing the equipment.

ti3430a

PAINT

FLUSH

ti3310a

Loading...

Loading...