Setup/Startup

12 3A3393C Operation

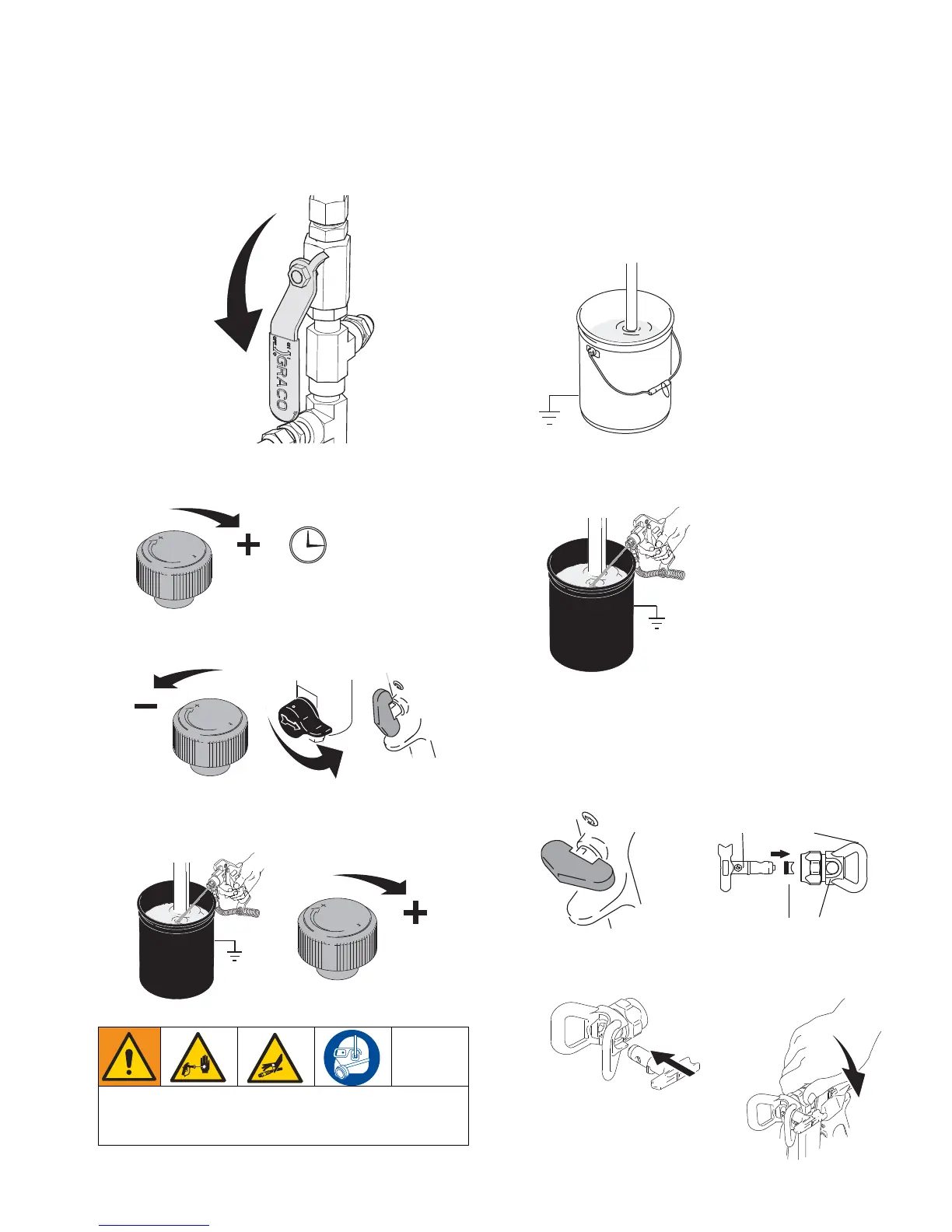

14. Set pump valve(s) ON (250SPS has one pump

valve; 250

DC has two pump valves). Pumps are now

active.

15. Increase pressure control enough to start pump.

Allow fluid to circulate for 15 seconds.

16. Turn pressure down, turn both prime valves hori-

zontal. Disengage gun trigger lock.

17. Hold all guns against a grounded metal flushing pail.

Trigger guns and increase fluid pressure slowly until

pumps run smoothly.

18. Inspect fittings for leaks. If leaks occur, turn sprayer

OFF immediately. Perform Pressure Relief Proce-

dure. Tighten leaky fittings. Repeat Startup, steps

1 - 17. If no leaks, continue to trigger gun until sys-

tem is thoroughly flushed. Proceed to step 18.

19. Place siphon tube in paint pails.

20. Trigger all guns again into a flushing fluid pail until

paint appears. Assemble tips and guards.

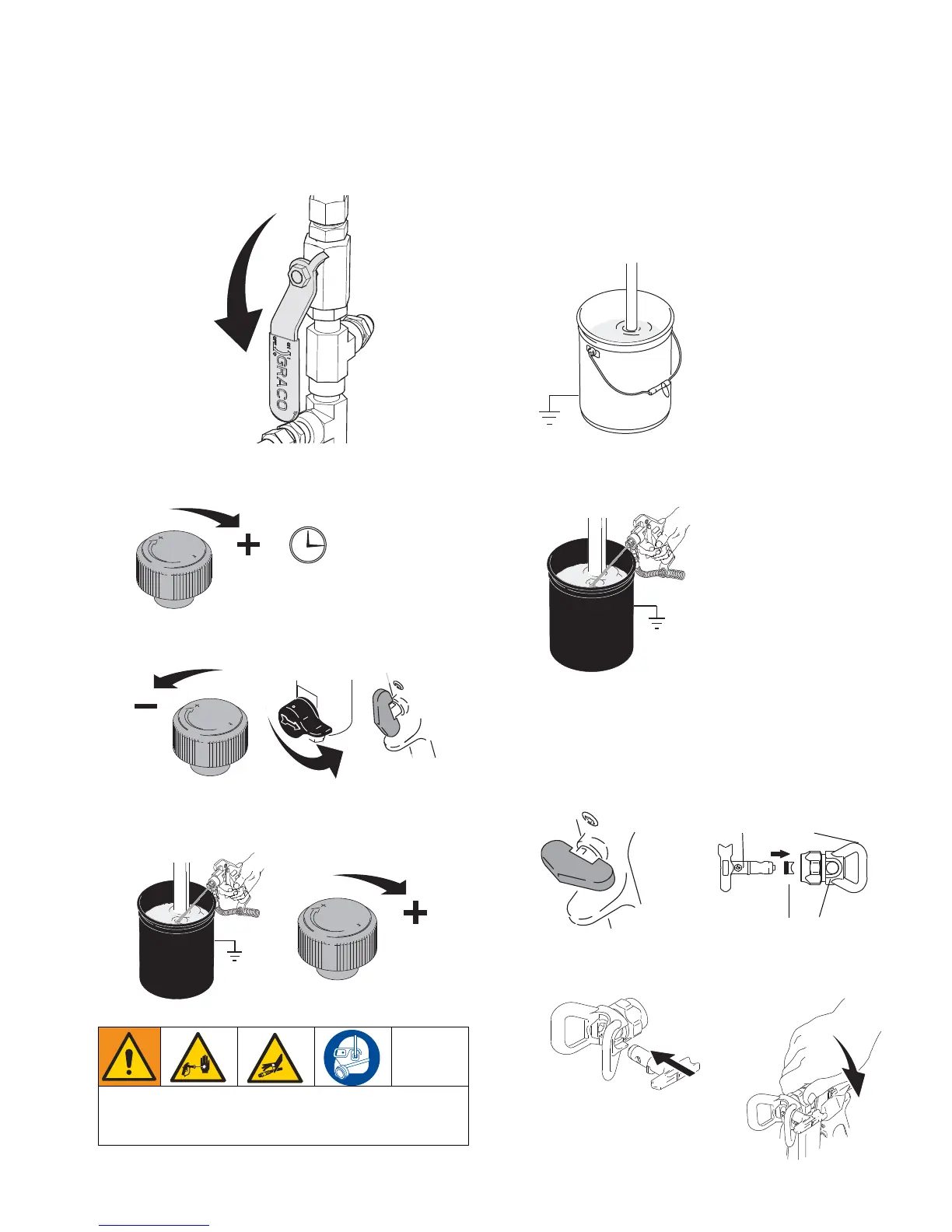

SwitchTip and Guard Assembly

1. Engage trigger lock. Use end of SwitchTip (A) to

press OneSeal (B) into tip guard (D), with curve

matching tip bore (C).

2. Insert SwitchTip in tip bore and firmly thread assem-

bly onto gun.

High-pressure spray is able to inject toxins into the

body and cause serious bodily injury. Do not stop

leaks with hand or rag.

PAINT

ti3316a

ti3324a

Loading...

Loading...