Grounding Procedure (For Flammable Flushing Fluids Only)

3A3393C Operation 9

Grounding Procedure

(For Flammable Flushing Fluids

Only)

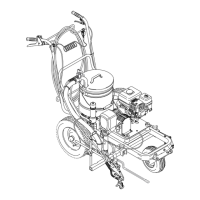

1. Position striper so that the tires are not on pave-

ment.

2. Striper is shipped with a grounding clamp. Ground-

ing clamp must attach to grounded object (e.g.

metal sign post).

3. Disconnect grounding clamp after flushing is com-

pleted.

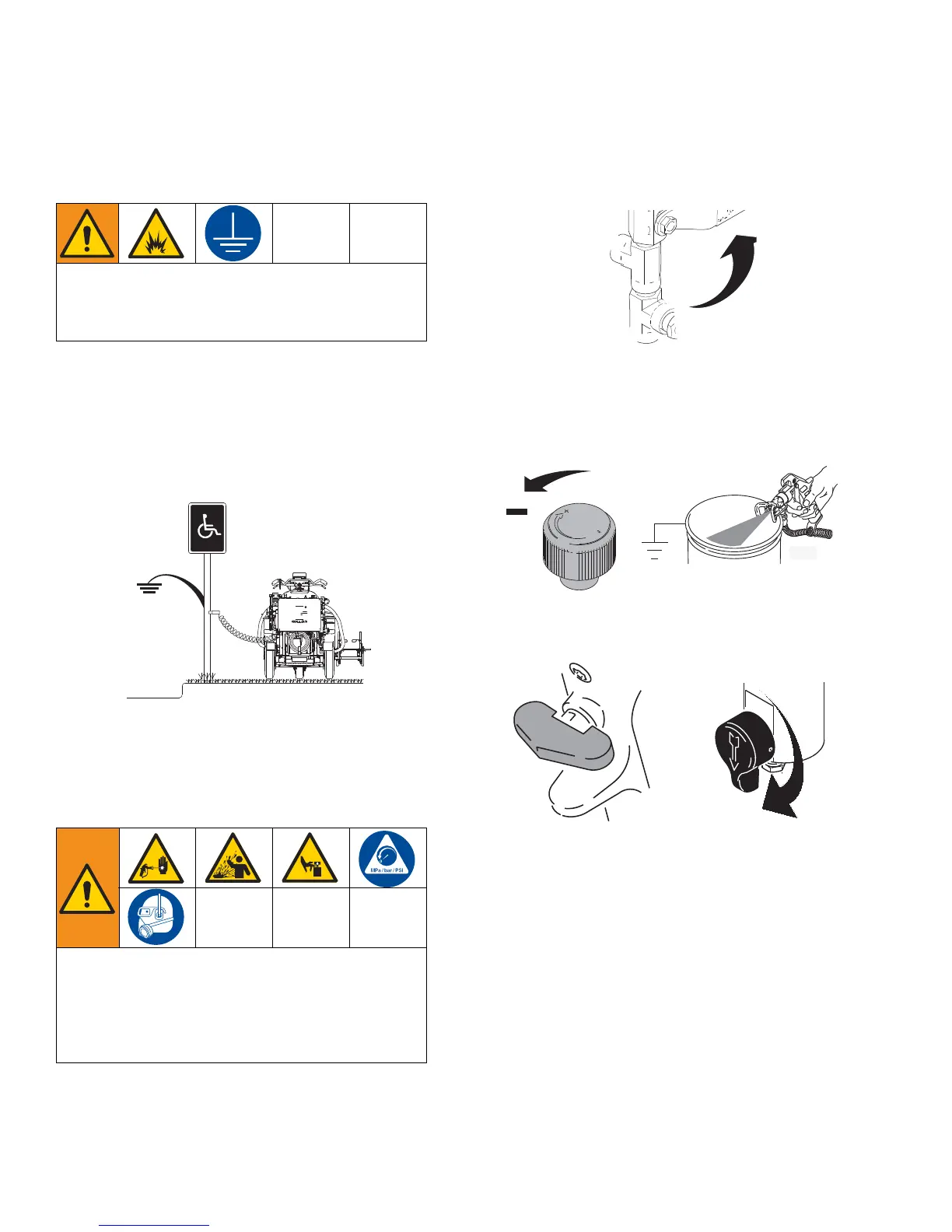

Pressure Relief Procedure

1. Perform Grounding Procedure if using flammable

materials.

2. Set pump valve(s) to OFF (250

SPS has one pump

valve; 250

DC has two pump valves). Turn engine

OFF.

3. Turn pressure control to lowest setting. Trigger all

guns to relieve pressure.

4. Engage all gun trigger locks. Turn prime valve(s)

down (250

SPS has one prime valve; 250DC has two

prime valves).

5. If you suspect the spray tip or hose is clogged or

that pressure has not been fully relieved:

a. VERY SLOWLY loosen the tip guard retaining

nut or the hose end coupling to relieve pressure

gradually.

b. Loosen the nut or coupling completely.

c. Clear the obstruction in the hose or tip.

This equipment must be grounded to reduce the risk

of static sparking. Static sparking can cause fumes to

ignite or explode. Grounding provides an escape wire

for the electric current.

This equipment stays pressurized until pressure is

manually relieved. To help prevent serious injury

from pressurized fluid, such as skin injection, splash-

ing fluid and moving parts, follow the Pressure Relief

Procedure when you stop dispensing and before

cleaning, checking, or servicing the equipment.

PAINT

ti3305a

ti3324a

Loading...

Loading...