GSK CNC Equipment Co., Ltd.

20

270

270

控制装置侧

PULS+

PULS-

SIGN+

SIGN-

R

R

VCC

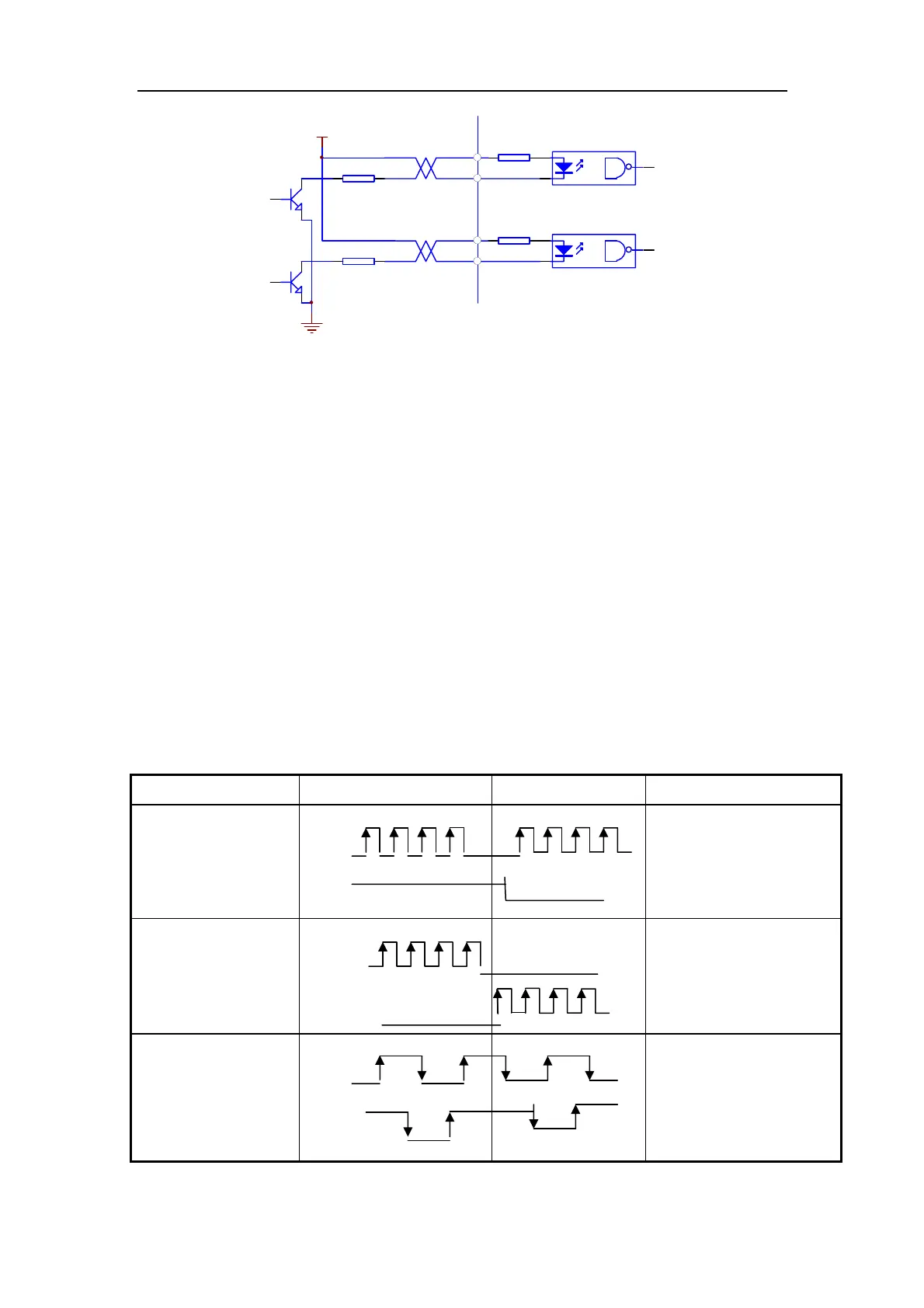

Fig. 3.8 Single terminal drive mode of pulse volume input interface

(1) It is suggested to apply differential drive mode to correctly transmit pulse volume

data;

(2) AM26LS31, MC3487 or RS422 linear driver are employed in the differential drive

mode;

(3) Action frequency will be reduced in single terminal drive mode. According to pulse

volume input circuit, Resistance R is determined by the max. 25V voltage of external

power and 10 ~15mA drive current of the pulse input circuit. Practical data:

VCC=24V,R=1.3~2K;VCC=12V,R=510~820Ω;VCC=5V,R=82~120Ω.

(4) Refer to Table

3-4 about pulse input form, arrowhead indicates counting curb, and

Table

3-5 shows pulse input time sequence and parameter. If two-phase input

form is employed, 4-fold pulse frequency is less than 500kHz.

Table

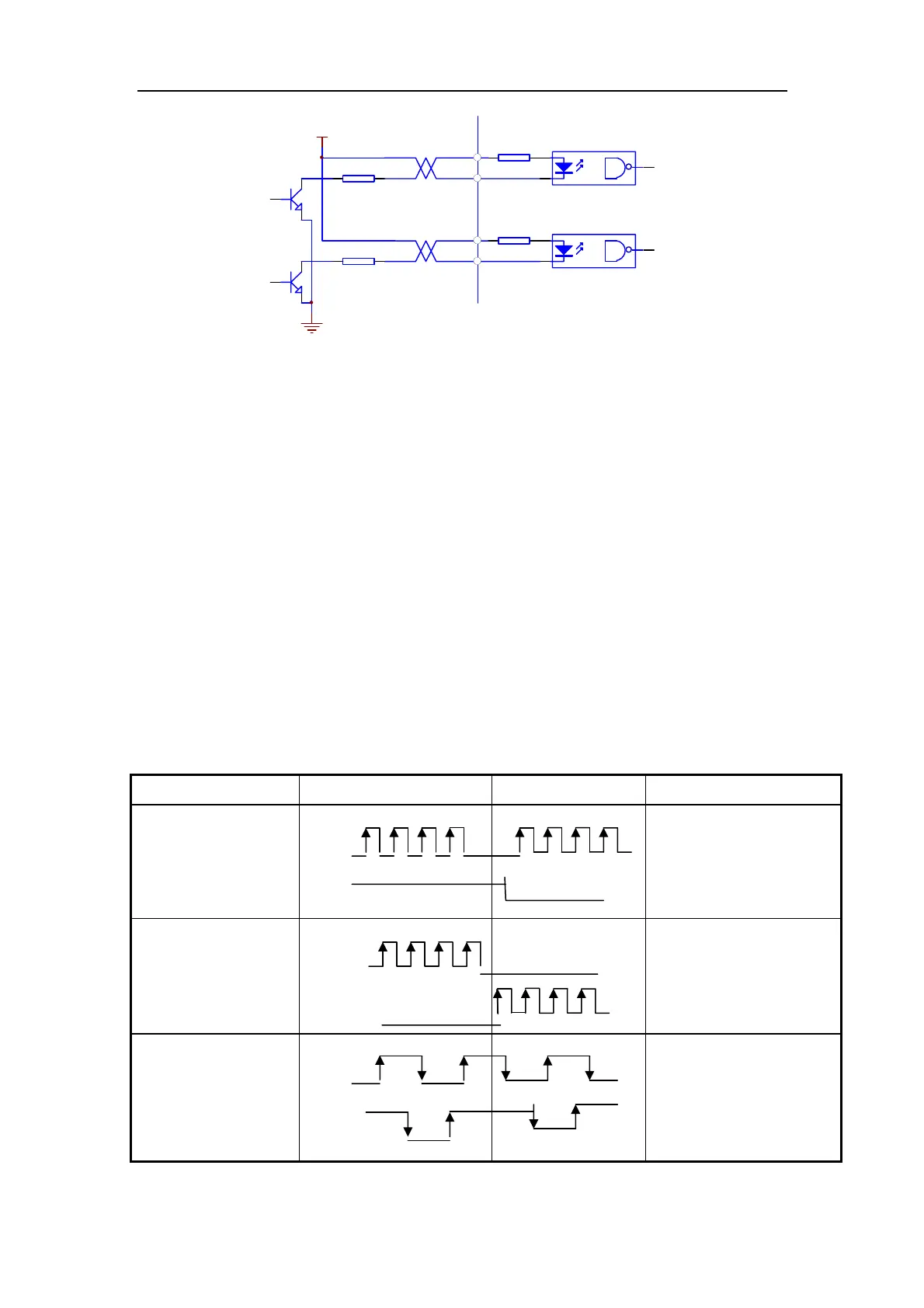

3-4 Pulse input pattern

Pulse instruction form CCW CW Parameter setting value

Pulse string sign

PULS

SIGN

0

Instruction pulse +sign

CCW pulse string

CW pulse string

PULS

SIGN

1

CCW pulse /CCW pulse

A phase pulse string

B phase pulse string

PULS

SIGN

2

2-phase instruction

pulse

Controller side

Loading...

Loading...