GSK CNC Equipment Co., Ltd.

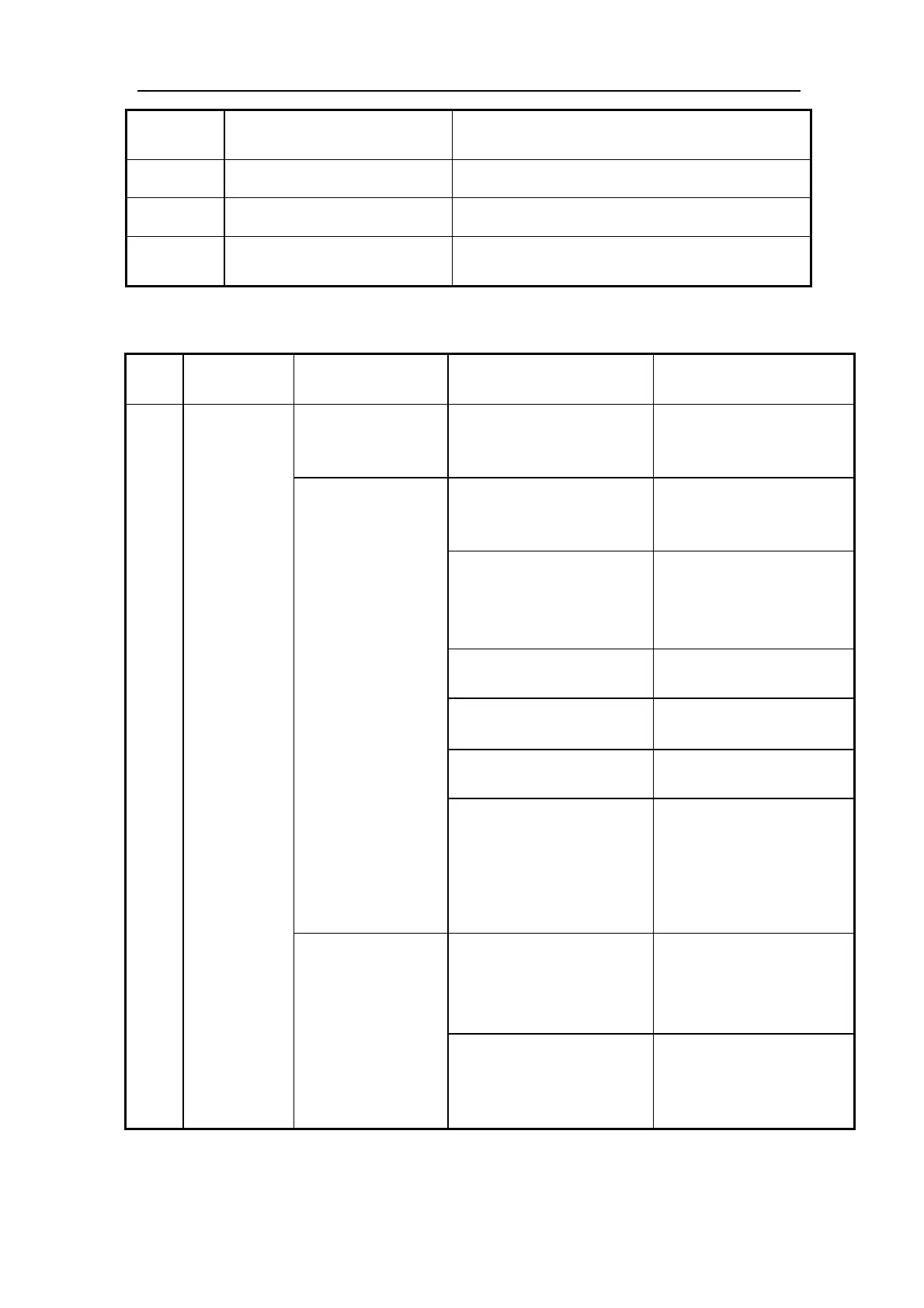

58

20

Data and detecting alarm of

EEPROM

EEPROM chip damaged

22 Zero-adjusting error of encoder Zero-adjusting fail of encoder

23 Current sampling fault Current sampling circuit fault

32

Encoder UVW signals code

invalid

Complete high or low level of UVW signals

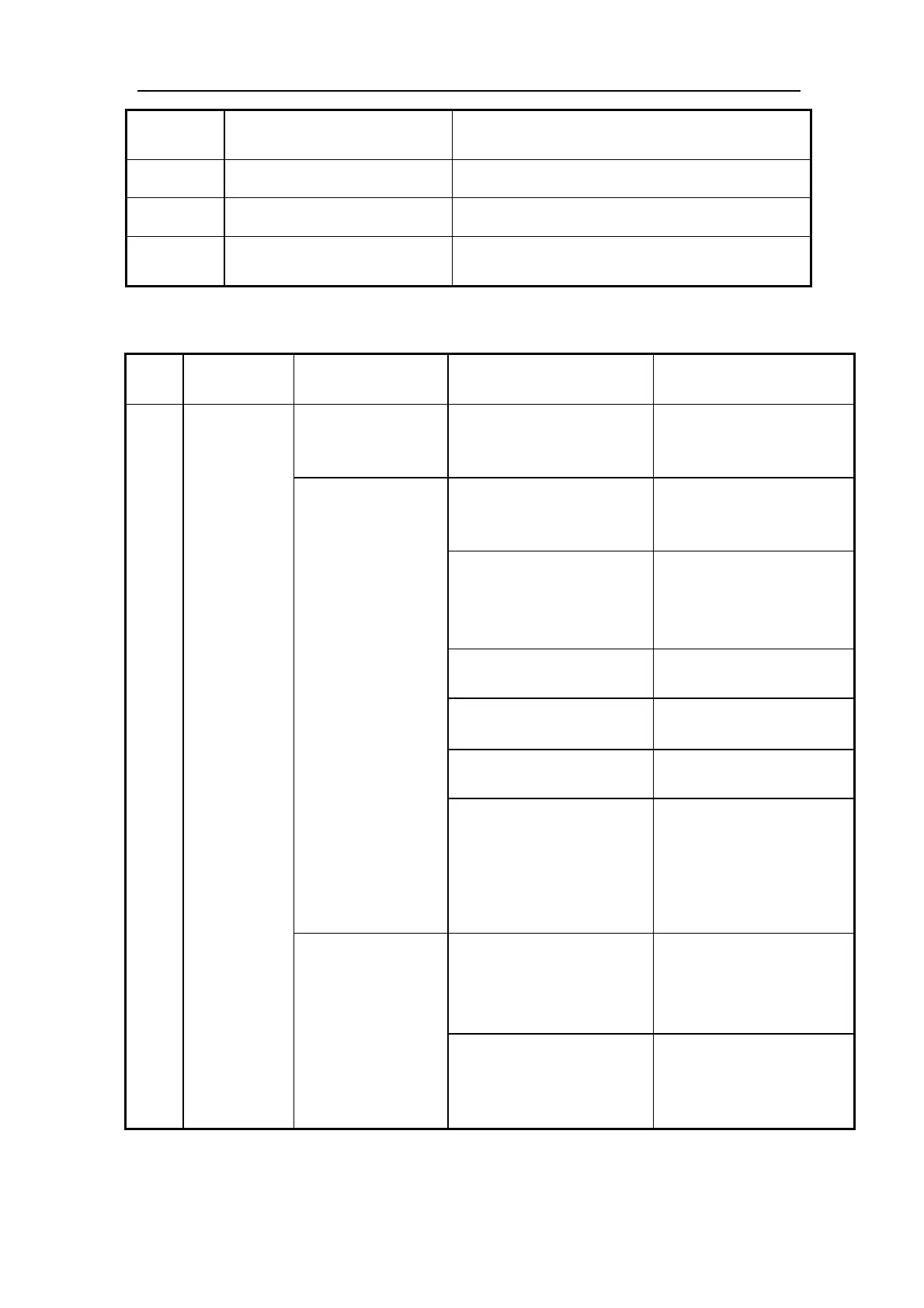

7.2 Alarm troubleshootings

Alarm

code

Alarm name Running state Cause Remedy

Occurring in switching

on control power

supply

① Control circuit board fault

② Encoder fault

① Change servo driver

② Change servo motor

① The frequency of

instruction pulse input is

overhigh.

① Set correctly the input

instruction pulse.

① Acceleration/deceleration

time constant is too small to

cause the speed

overshooting too large.

①Increase acceleration

/deceleration time constant.

① The electronic gear ratio

input is too large.

① Set it correctly.

① Encoder fault ① Change the servo motor.

① Encoder cable is inferior.

① Change the encoder cable.

Occurring in motor

running

① Servo system is not stable

to cause the overshooting.

① Set the related gain

again.

② If the gain can not be set

to a proper value, reduce

rotation inertia ratio of load.

① The load inertia is too large.

① Reduce load inertia.

② Change driver and motor

with larger power ones.

Err-1 Overspeed

Occurring in the

starting of the motor

① Encoder zero fault

① Change servo motor.

② Re-adjust encoder zero

by manufacturer.

Loading...

Loading...