GSK CNC Equipment Co., Ltd.

40

immediately be reflected in the control process, press‘ ’or‘ ’to go on modify

parameters till the completion of modification, then press

‘ ’to back to parameter

selection mode. Do not press‘

’to confirm if the parameters modified are not proper,

press

‘ ’to cancel it to make the parameter recover to its original value and back to the

parameter selection mode.

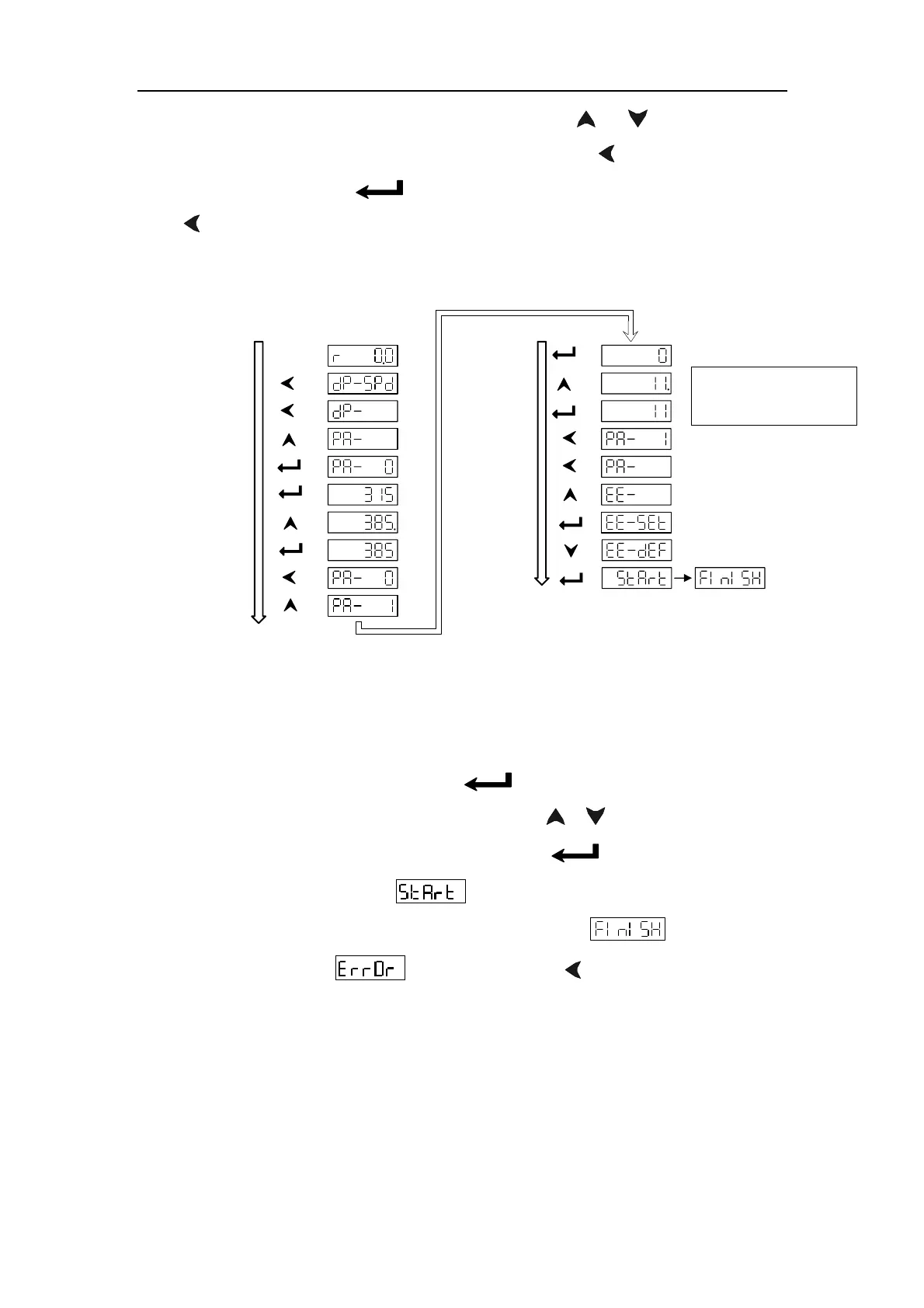

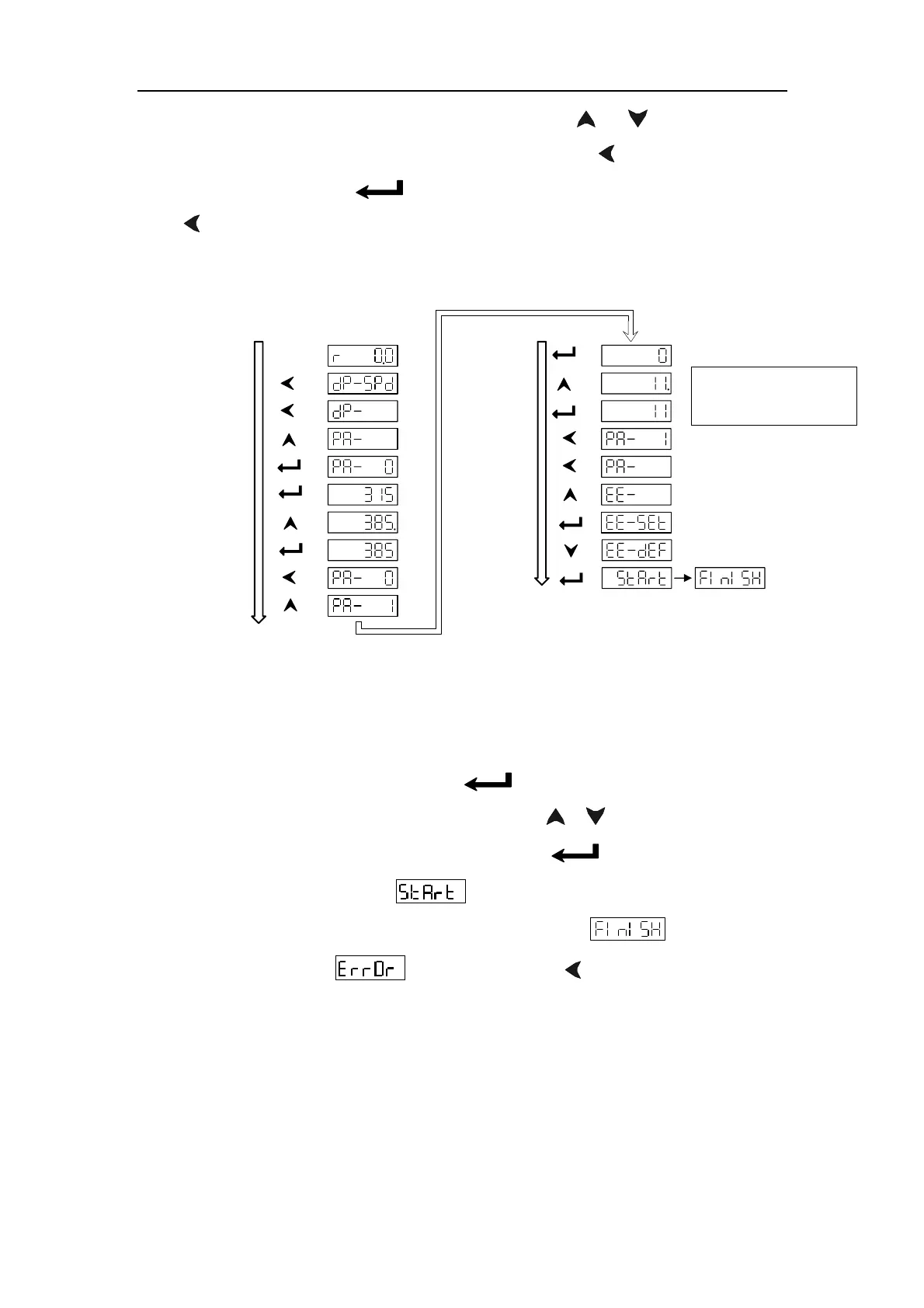

The following is the parameter setting procedure for GSK 110SJT-M040D servo motor

:

Power on

Back a layer

Menu selection

Back a layer

Forward a layer

Parameter value

Modification

Confirmation

Back a layer

Parameter selection

Default call

Parameter value

Modification

Confirmation

Back a layer

Back a layer

Menu selection

Forward a layer

Hold for 2s

Fig. 5.5 Diagram block of parameter setting

5.4 Parameter management

The parameter management is mainly used for memory and EEPROM operation.

Select “EE-” in the first layer and press‘

’to enter into parameter management

mode. 5 operation modes can be selected by

‘ 、 ’keys. For example, for

“ parameter writing ” , select “EE-Set”,then press‘

’and hold it on for over 1

second, the monitor displays “

” that means the parameter is being written

into EEPROM. After 1~2 seconds, the monitor displays “

” if the writing is

successful, otherwise“ ” is displayed. Press ‘ ’again to return to operation

selection mode.

z EE-Set: parameter writing. It means to write the parameters in the memory into

EEPROM parameter area. The parameters modified by user only change the

parameter values in the memory that they will restore to their original values after

power is on again. If the parameter values are changed permanently, parameter

writing should be executed to write the parameters in the memory into the

EEPROM parameter area, so the modified parameter values will be valid after

Model code parameter

of the respective motor

Loading...

Loading...