Chapter 6 Trial run

47

with zero speed. If the motor runs in low speed, adjust the parameter PA22 to make the

motor to be in zero speed state.

3) Slowly adjust the analog voltage, the motor speed will vary by the voltage variation. The

highest motor speed in ±10V input voltage can be adjusted by modifying parameter

PA29. Be attentive that the highest running speed is limited by PA23.

4) Modify parameter PA19 if the rotation direction is required to be changed.

When PA19=0, motor runs forward (CCW) for positive voltage, backward(CW) for

negative voltage;

When PA19=1, motor runs backward (CW) for positive voltage, forward(CCW) for

negative voltage;

5) If vibration occurs in the CNC closed loop running, adjust parameter PA08 for feedback

filtering.

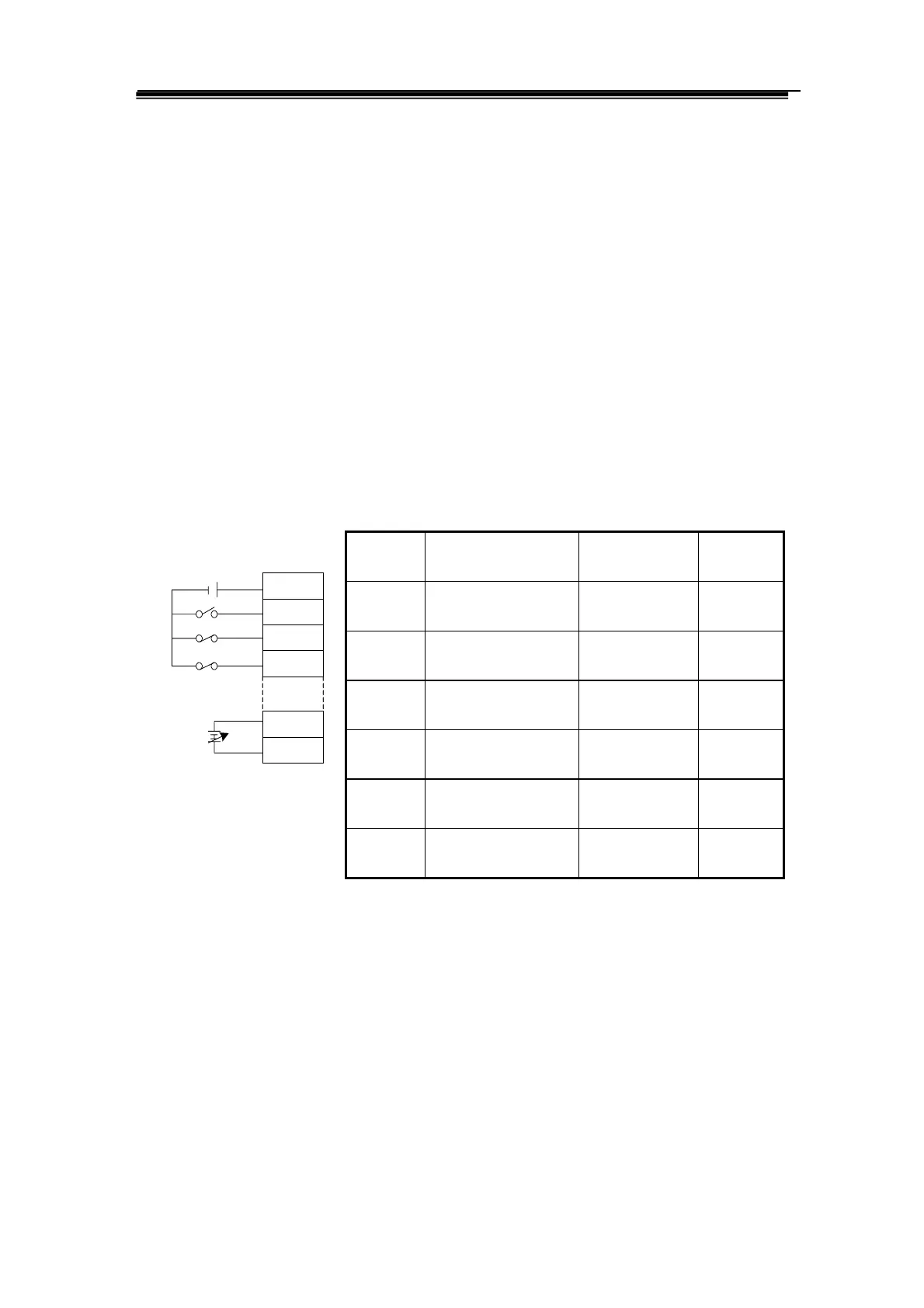

Wiring diagram block: pameter list

Sequence

number

Name Setting range Factory

setting

PA04 Control mode

selection

0~6

1

PA08 Low pass filter for

speed detecting

1~5000

200

PA19 Reverse of analog

speed

0~1

0

PA22 Instruction deviation

of analog speed

-500~500

0

PA23 Highest speed setting

for motor

-30000~30000

25000

PA29 Highest speed of

analog instruction

-30000~30000

25000

Fig.6.2 Wiring for analog instruction control

Wirings for two types of CNC system for milling machines made by us.

COM+

SON

FSTP

RSTP

VCMD

AGND

DC

12-24V

DC

-10V-+10

38

23

24

9

17

1

Loading...

Loading...