Chapter 9 Order guide

69

9.1 Capacity selection

Servo capacity is relative to the load inertia, the load torque, the orienting precision and

max. speed required which are taken into account by the following steps:

1) Calculation of inertia and torque of load, torque of acceleration and deceleration

① Calculation of torque

The load torque is caused by the friction and cutting force of the driver.

2πM = FL

M ── Torque of motor shaft

F ── Force required for moving the mechanical parts in linear direction

L ── Distance of moving mechanically for a revolution (2 π rad) of

motor

2πM is the work done by the motor torque M in a revolution, while FL is the

work done by force F moving an object for L distance.

Practically, due to the factors of transmission efficiency and friction coefficient,

the torque required by ball screw overcoming the external load force P for

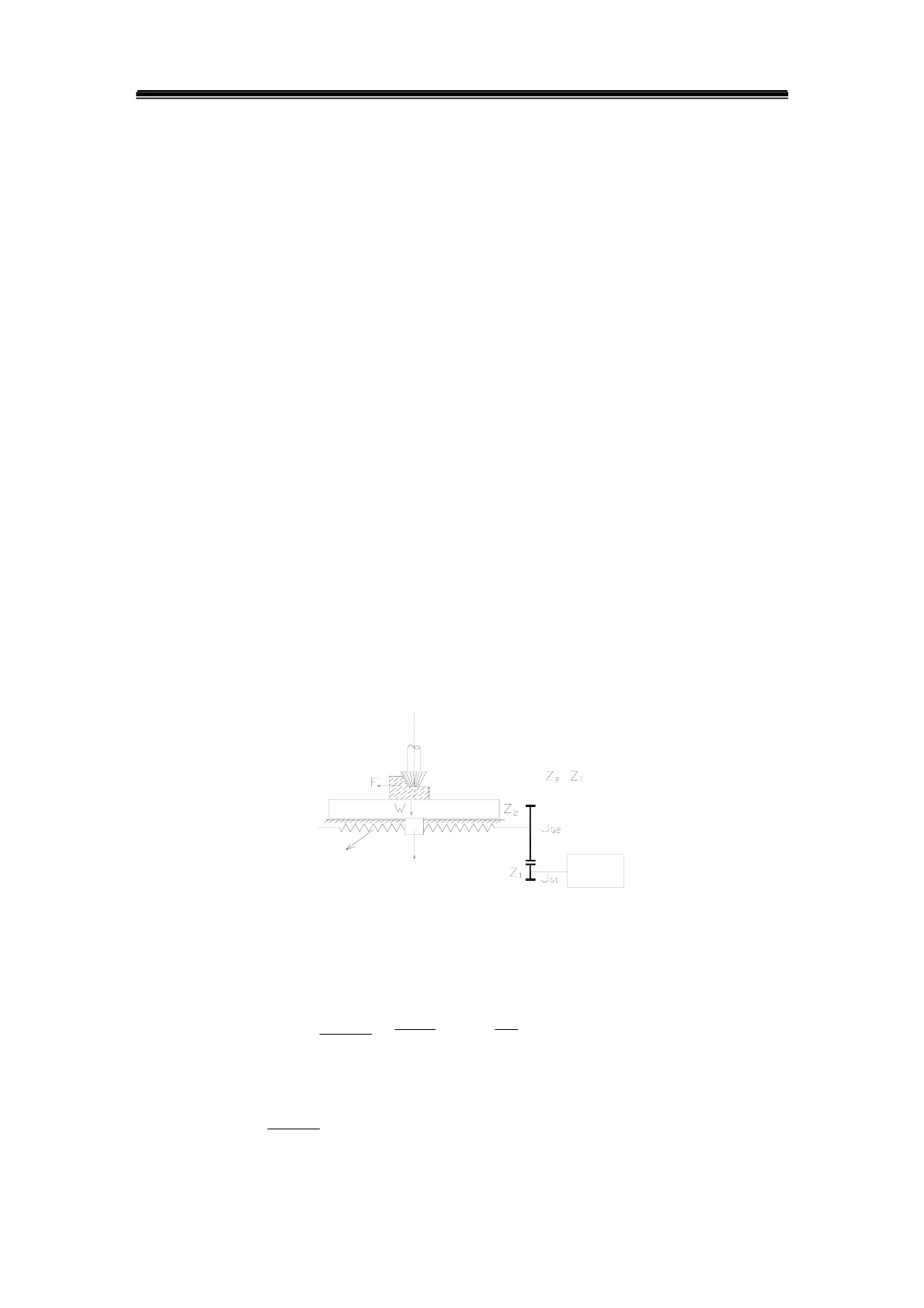

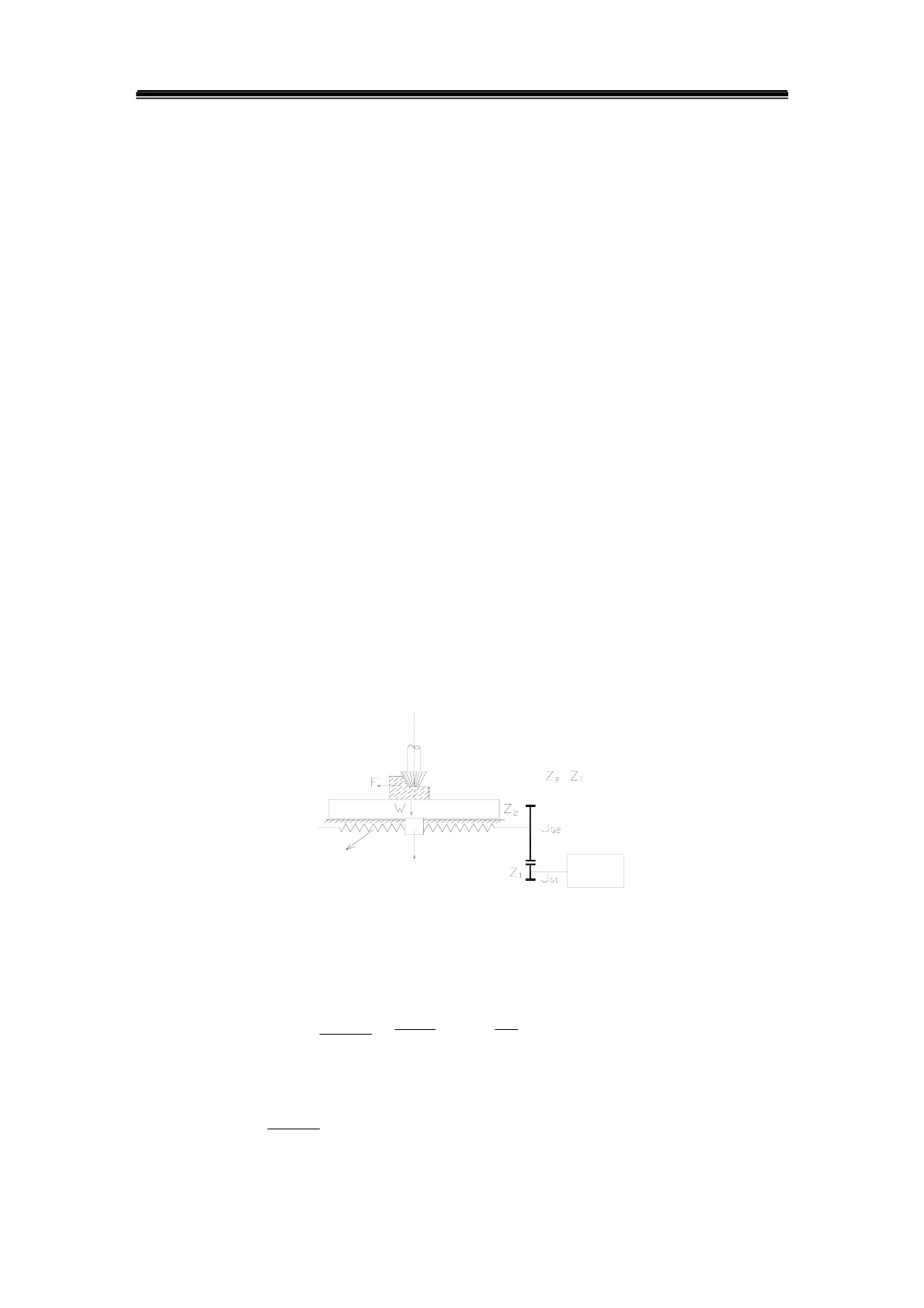

uniform velocity movement is shown as following diagram:

With pre-fastened

double nuts

Servo

motor

Ball screw

, -Tooth number

An example for servo feeding drive system

Calculate it by the following equation:

M

1

=(K

π

2

F

0 spa

h

+

1

2

P

πη

sp

h

+M

B

)

2

1

Z

Z

M

1

—— Drive torque for uniform velocity movement

K

π

2

F

0 spa

h

—— Pre-fastened torque of double nuts ball screw(N•mm)

F

a0

——Pre-fastened force, it generally amounts to one third of the

Chapter 9 Order guide

Loading...

Loading...