27

L

B

H

!

"

$

#

%

&

!

"

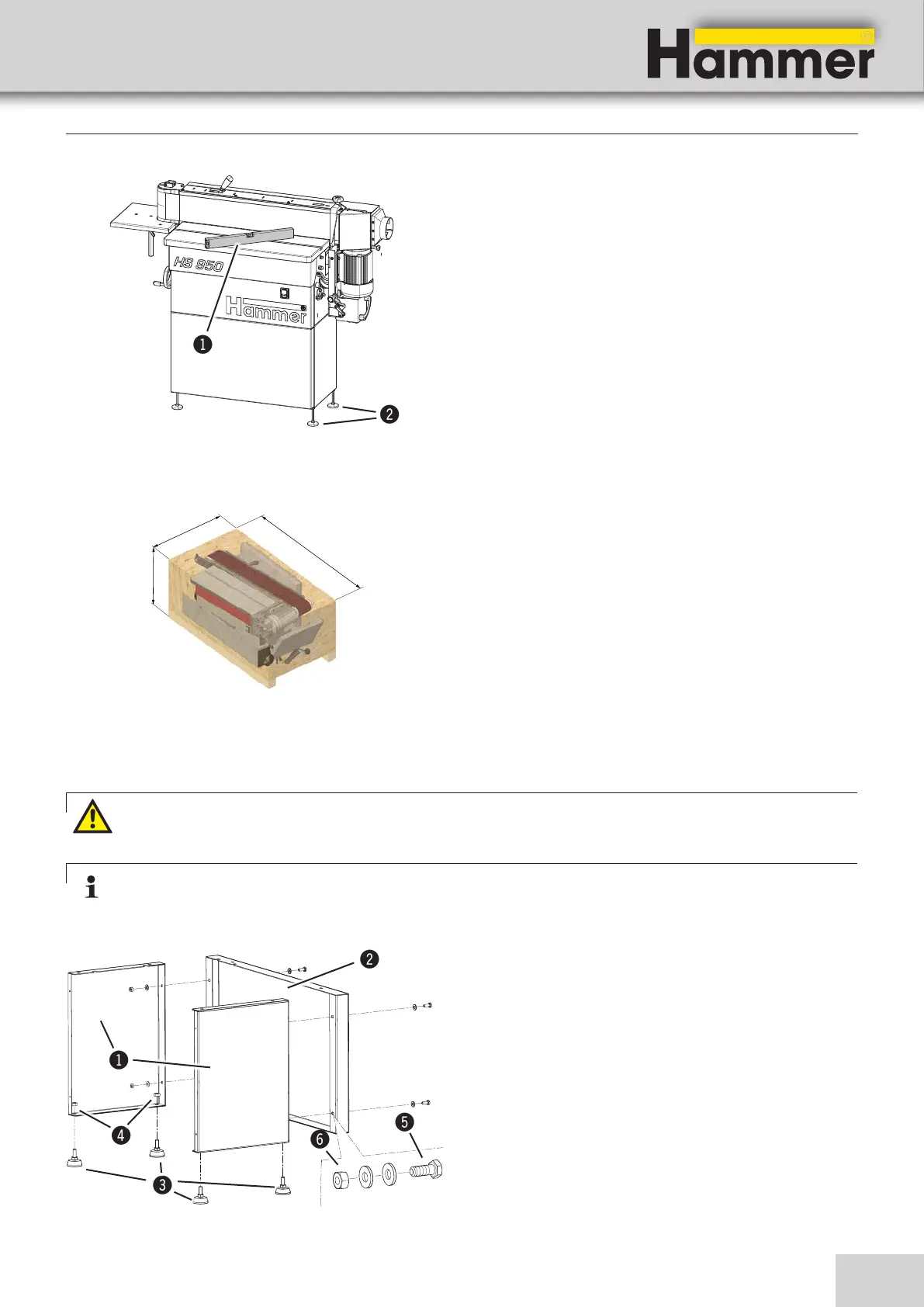

Edge sanders

HS 950

The machine is shipped mounted on a pallet.

Carefully remove the lid and side walls of the pallet.

Store the loose components cleanly and safely.

Remove the transport brackets before moving the machi-

ne to the installation location

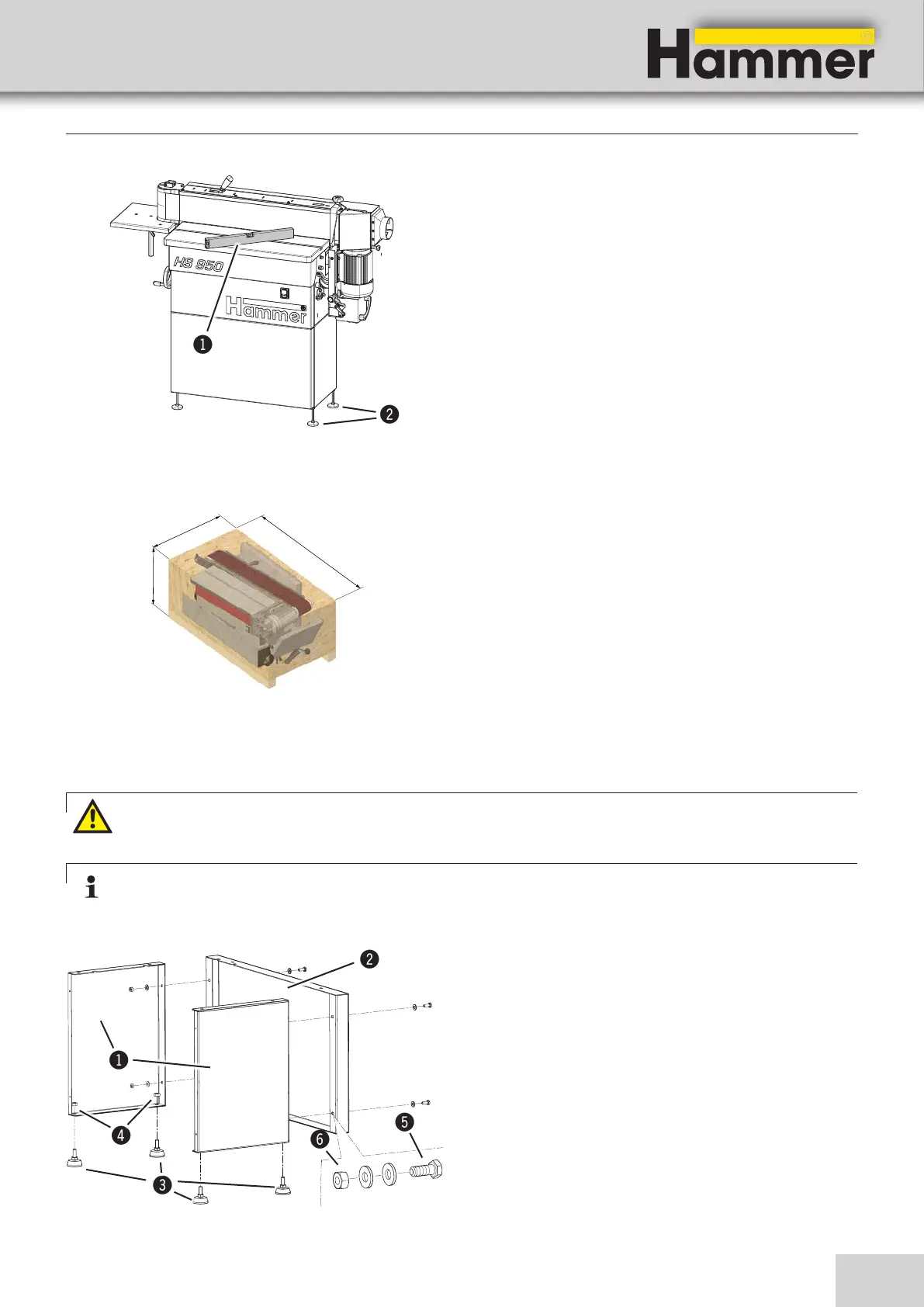

1. Fix the adjusting screws with the nut (4 x M10) to the

side sheet metal parts.

2. Fasten the two side sheet metal parts onto the sheet

metal front part using the screws and nuts (4 x M8).

! Side sheet metal

" sheet metal front

# Adjusting screws

$ Nut (M10)

% Screw (M8)

& Nut (M8)

1. Transport the machine to the installation site as

instructed in the “Transport“ chapter and the enclo-

sed transport or installation instructions.

2. Position the machine with the aid of a spirit level

to ensure that the machine functions precisely and

operates smoothly.

Even out uneven floors by setting the adjusting screw

or by bolstering the machine.

! Spirit levels

" Adjusting screws

Setup and installation

7.3 Machine assembly

Fig. 7-2: Positioning the machine

Fig. 7-3: Machine packaging

7.3.1 Assemble machine frame

Warning! Heavy dead weights can easily cause an injury

To facilitate assembly, ensure the presence of a minimum of one additional people.

Take measures to prevent the machine from slipping sideways.

Note:

During the assembly of the machine frame, first loosely connect all parts.

Finally, tighten all screws.

Fig. 7-4: Assemble machine frame

Loading...

Loading...