31

!

X

Y

Edge sanders

HS 950

Setup and installation

7.4 Chip extraction

Warning! Risk of injury!:

Vacuum hose must be flame-resistant and must conduct electricity! Be sure to use only genuine Hammer

vacuum hoses!

Note: As a rule, all units must be vacuumed during use. A time delayed socket is available as an accessory.

• The dust extractor must be connected to the machine

in such a manner that it runs in unison with the

machine.

• The dust extraction hoses must be electrically conduc-

tive and grounded to prevent electrostatic

build up.

• Use dust extractors with reduced dust emission to clean

dust from the machine.

• In addition, the vacuum performance must be sufficient

to achieve the required negative pressures and an air

speed of 20 m/s at the connector. (see “Technical

data”)

• Check the air speed before putting the machine into

operation for the first time and after essential changes.

• The dust extractor setup must be controlled before the

machine is put into operation for the first time. Check for

obvious defects on a daily basis and the efficiency on a

monthly basis.

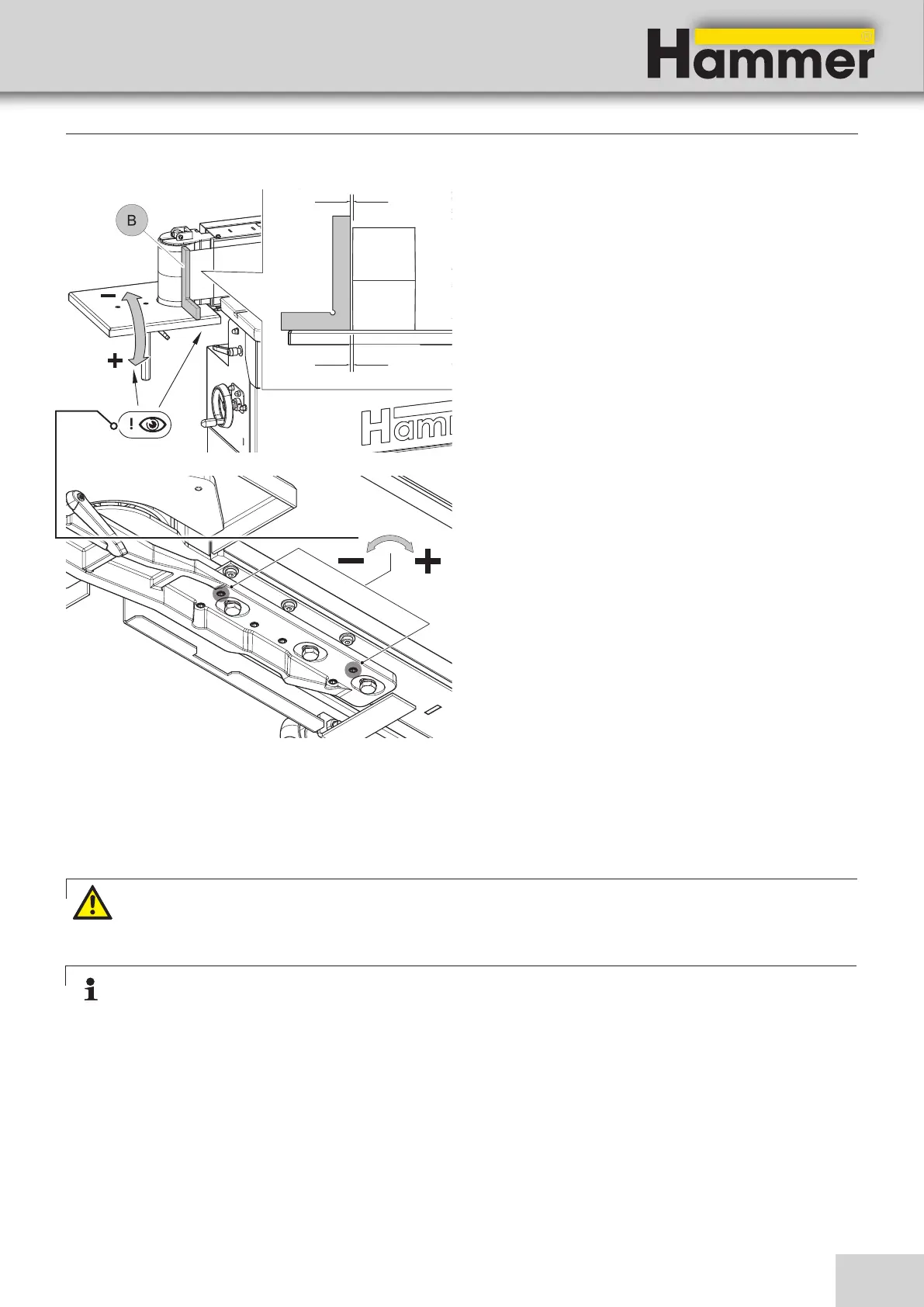

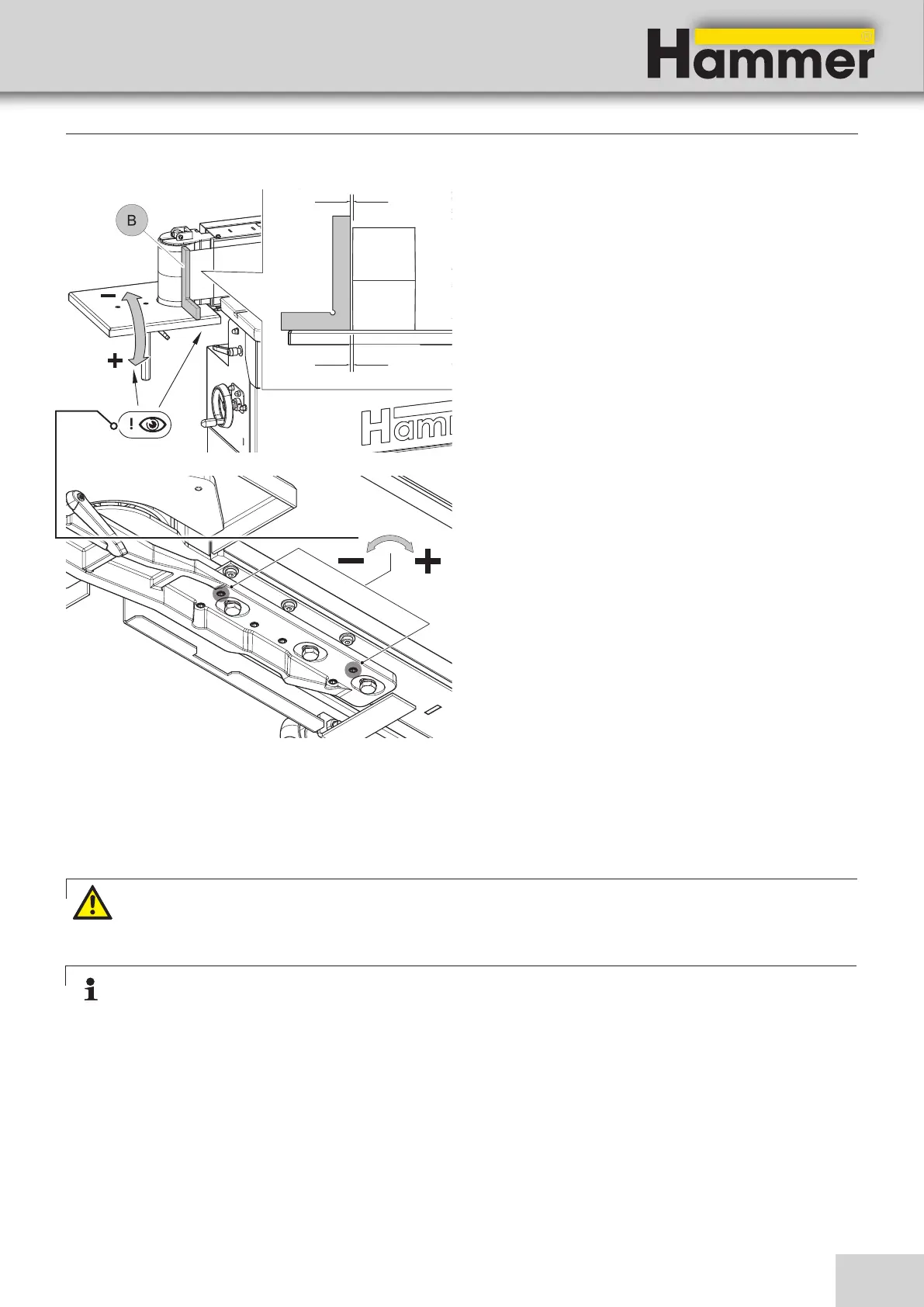

Angle B:

1. Place a 90° angle between the roller and the side

work table.

2. Measure the distance Y and X. The values X and Y

must be equal.

3. Loosen the hexagonal screws.

Release the fixing screws

Setting - at X>Y:

• Adjusting in the „-“ direction

Setting - at X<Y:

• Adjusting in the „+“ direction

4. Tighten the hexagonal screws.

Tighten the fixing screws

!Socket head cap screw

"Fixing screws

#clamp

Fig. 7-13: Setting - Angle B

Loading...

Loading...