30

!

"

!

X

Y

!

"

!

Edge sanders

HS 950

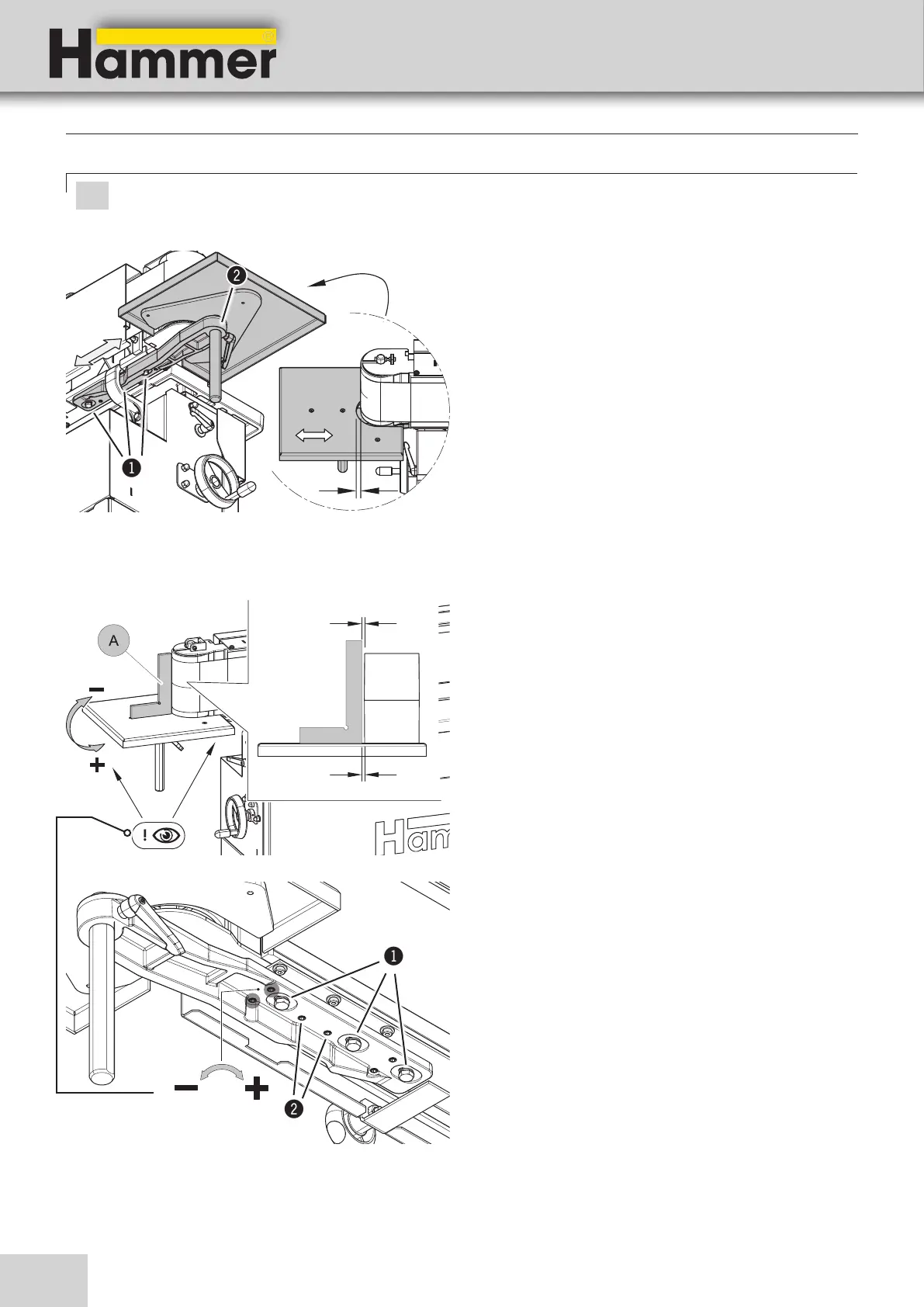

Setting: Distance of the roller to the side working table

1. Loosen the hexagonal screws.

2. Move the clamp along the slotted holes.

3. Tighten the hexagonal screws.

!Socket head cap screw

"clamp

Setup and installation

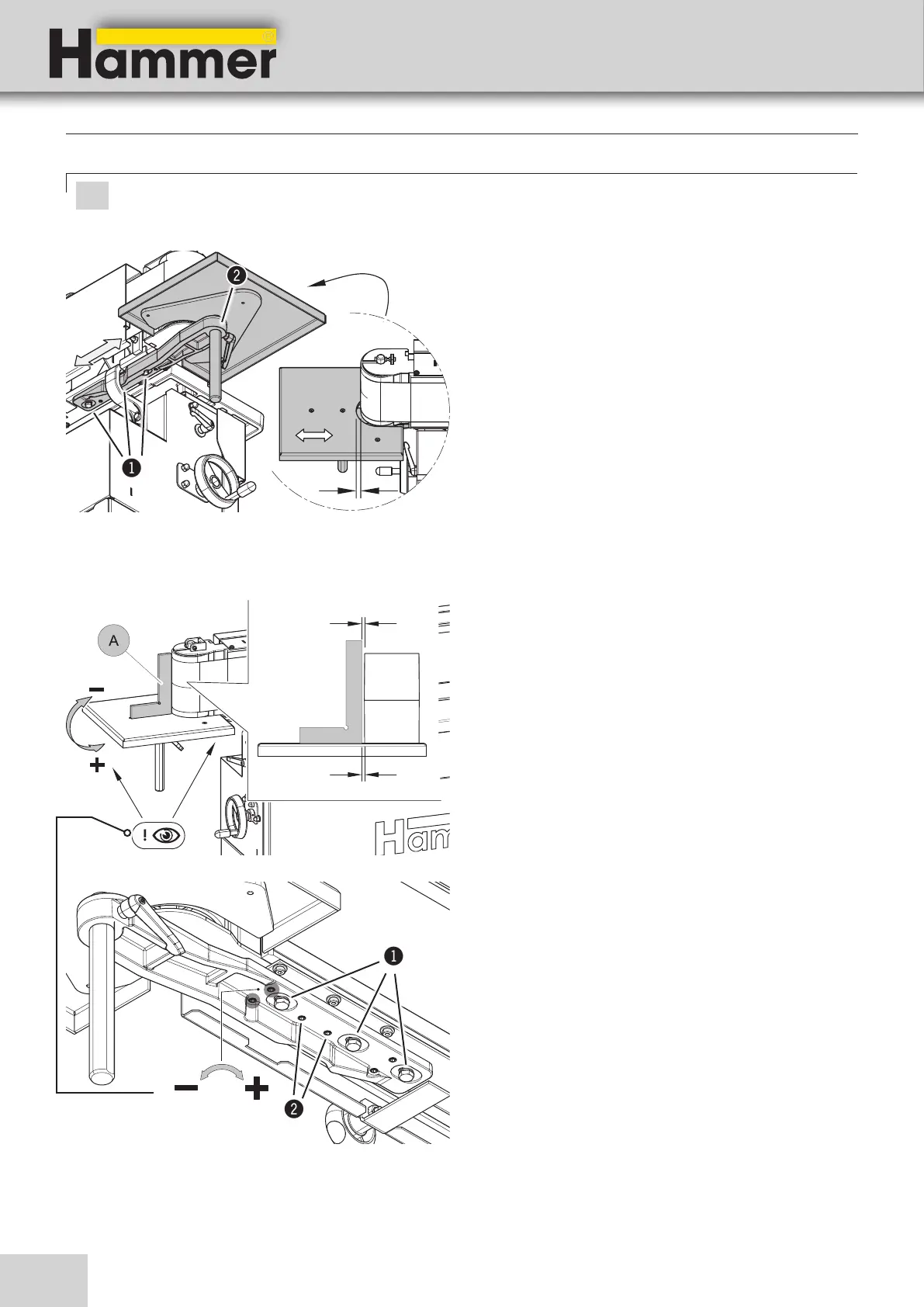

Setting: 90° angle of the roller to the side working table

Angle A:

1. Place a 90° angle between the roller and the side

work table.

2. Measure the distance Y and X . The values X and Y

must be equal.

3. Loosen the hexagonal screws.-

Release the fixing screws

Setting - at X>Y:

• Adjusting in the „-“ direction

Setting - at X<Y:

• Adjusting in the „+“ direction

4. Tighten the hexagonal screws.

Tighten the fixing screws

!Socket head cap screw

"Fixing screws

#clamp

Fig. 7-11: Setting - side working table

Fig. 7-12: Setting - Angle A

Attention! Risk of material damage!:

Set the working table with sufficient distance to the sanding belt! There is the risk of collision.

Loading...

Loading...