42

Edge sanders

HS 950

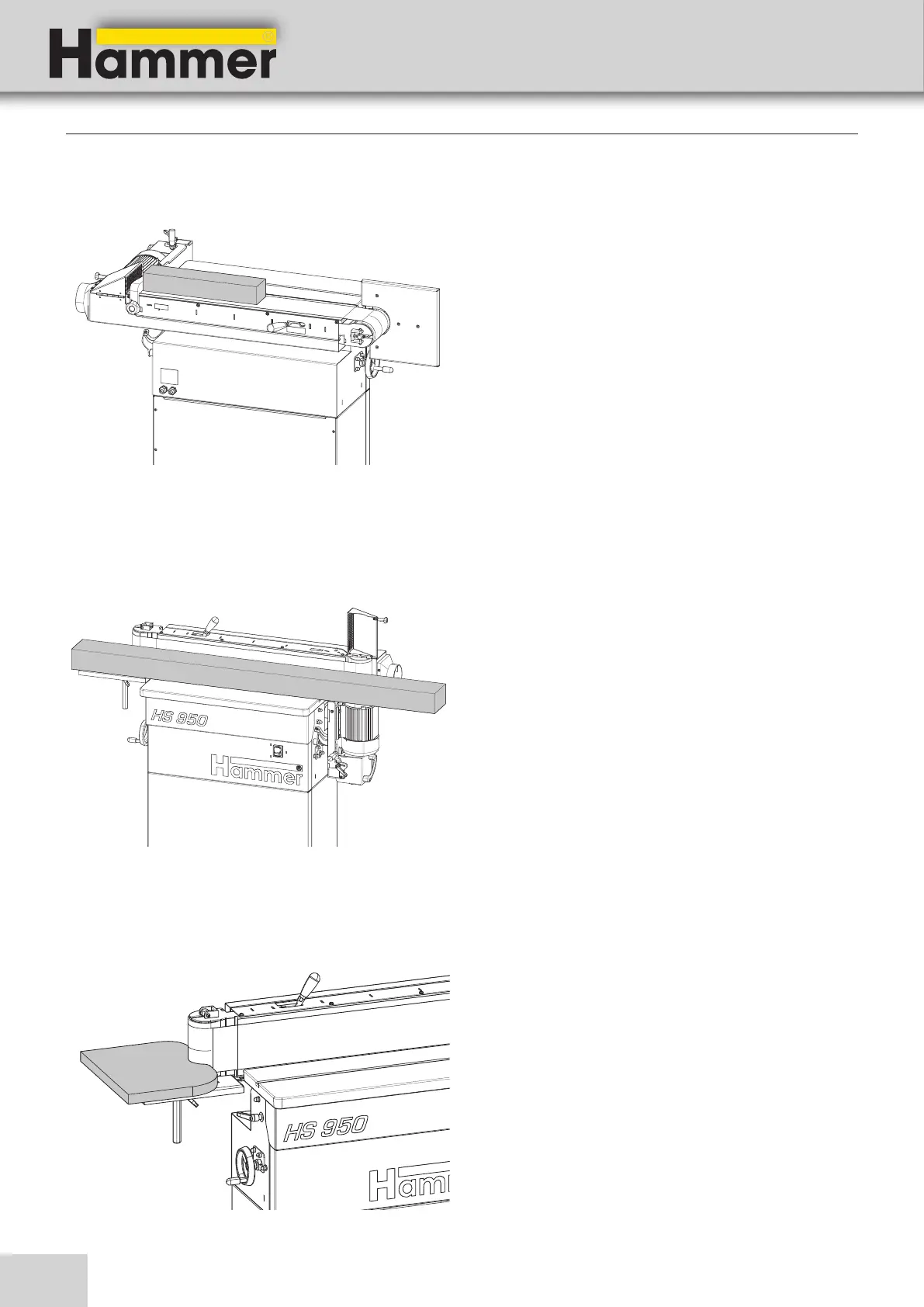

9.4.6 Face grinding at 0°

This step enables you to face grind workpieces up to a

width of 150 mm.

1. Take note of general procedures for authorized

working techniques.

2. Adjust the table height to the workpiece to be ma-

chined. Swivel the sanding unit to the 0° position.

3. Check that all clamping levers are tightened firmly.

4. Switch machine on.First place the workpiece against

the fence and then guide it to the abrasive belt. Car-

ry out machining until the surface has been sanded

cleanly.

This operation is used for grinding curved workpieces

with large bends.

Place the workpiece on the side working table.

1. Take note of general procedures for authorized

working techniques.

2. Adjust the table height to the workpiece to be ma-

chined.

3. Check that all clamping levers are tightened firmly.

4. Switch machine on. Hold the workpiece to the abra-

sive belt until the surface is sanded cleanly.

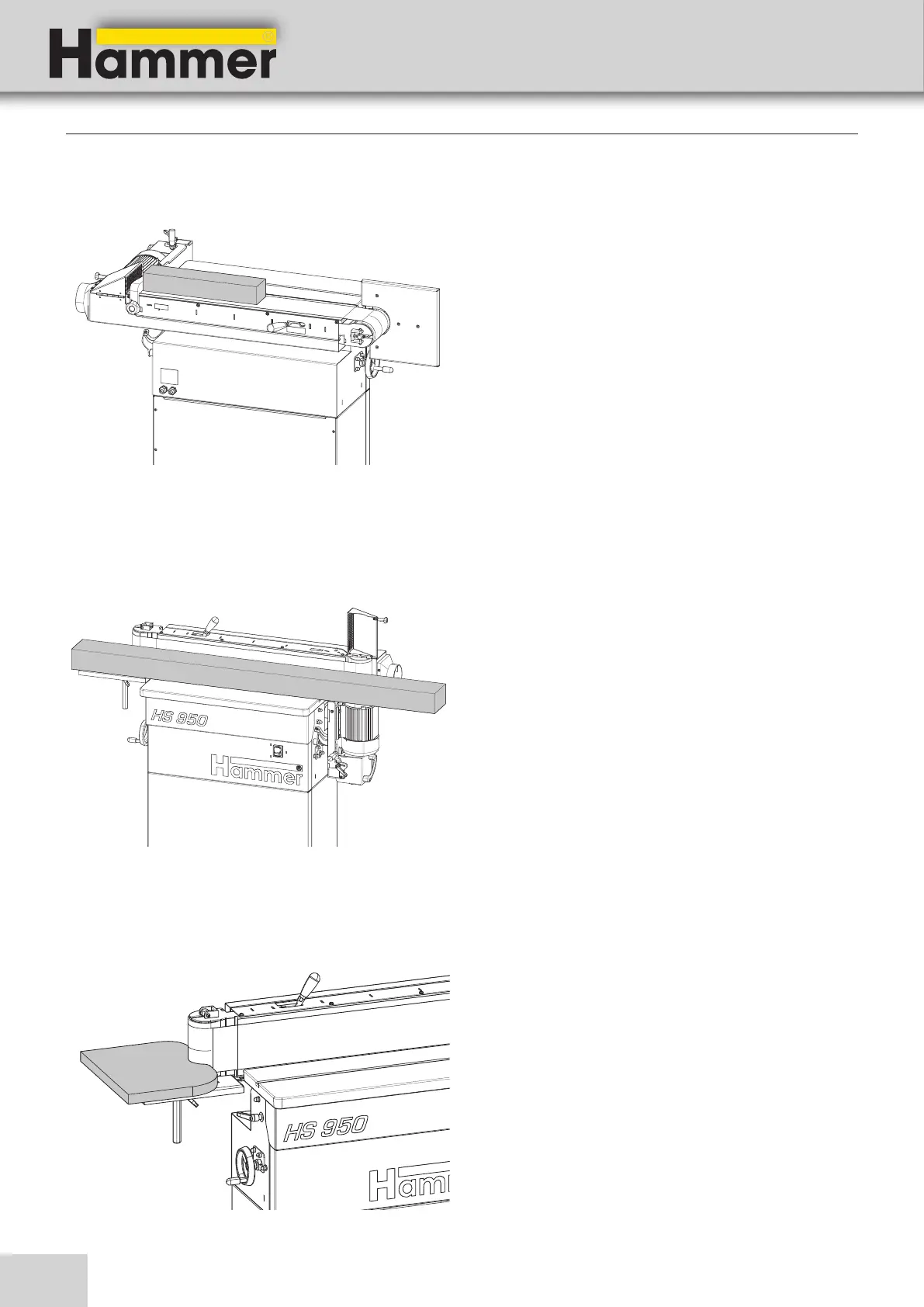

Extending the machining area (long workpieces)

See chapter entitled 8.7

This makes it possible to easily sand extra long workpi-

eces

with ease.

1. Take note of general procedures for authorized

working techniques.

2. Adjust the table height to the workpiece to be ma-

chined.

3. Check that all clamping levers are tightened firmly.

4. Switch machine on. Hold the workpiece to the abra-

sive belt until the surface is sanded cleanly.

9.4.7 Grinding of long workpieces

9.4.8 Grinding on the roller

Operation

Fig. 9-6: Face grinding at 0°

Fig. 9-7: Grinding of long workpieces

Fig. 9-8: Grinding on the roller

Loading...

Loading...