48

X

"

!

Edge sanders

HS 950

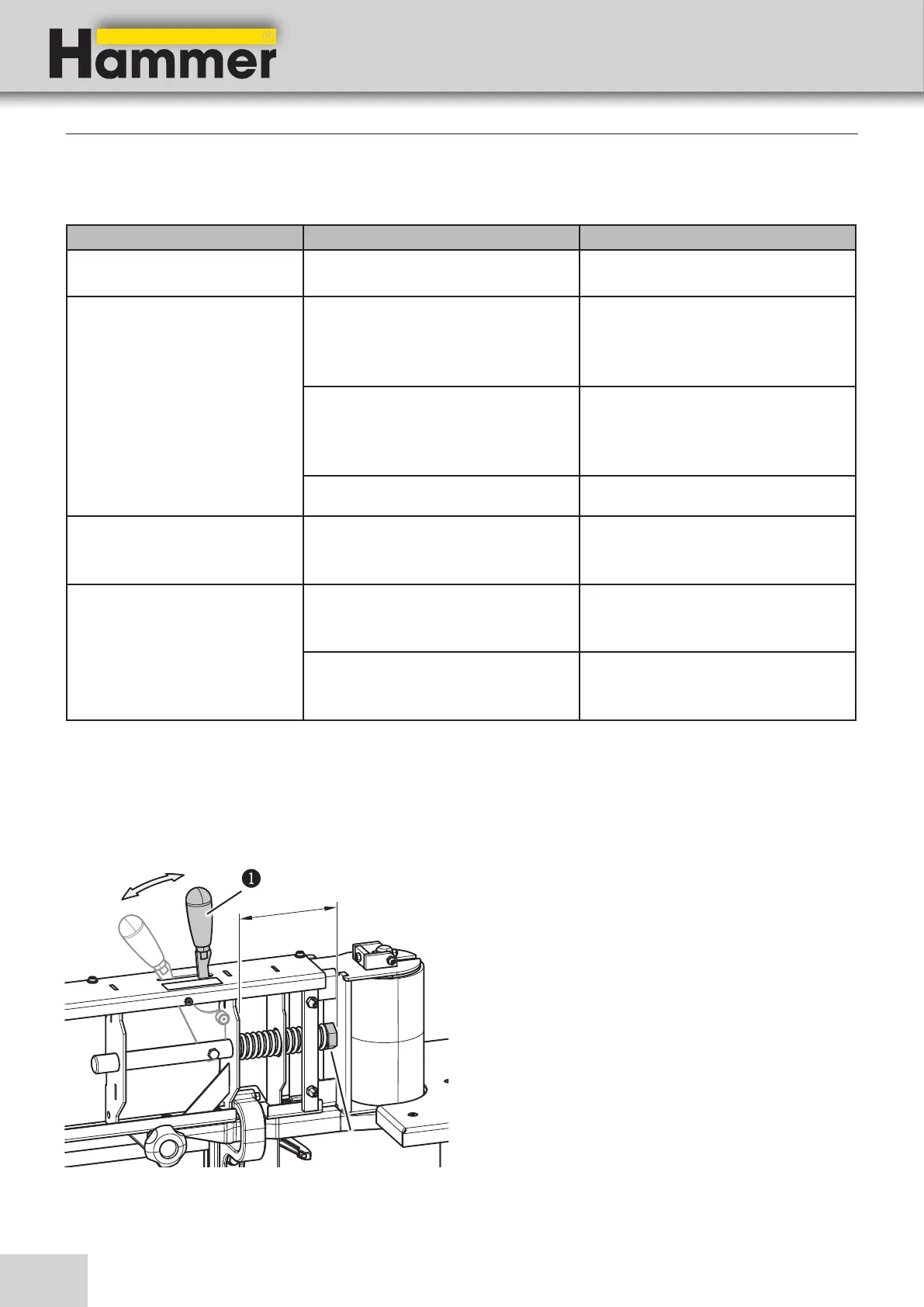

Fault Possible cause Repair

The workpieces are being

sanded diagonally

Abrasive belt support is not parallel Contact service technician

Lines are appearing in the

workpiece length during the

sanding process

The sanding belt grains are crushed or

the sanding belt is damaged as a result

of irregularities on the workpieces (e.g.

due to protruding nails)

Hook a new sanding belt around and

feed the workpieces over the whole

width

The sanding belt is covered with glue

or dust from previously sanded work-

pieces

Hook a new sanding belt around.

Ensure that the workpieces do not have

any protruding nails or contain any

undesired impediments

Sanding belt - The guides are dirty Clean the appropriate part

Cross lines have appeared in the

workpiece width

The weld on the sanding belt has a

difference in thickness which shows on

the workpiece

Place another sanding belt around;

take note of the correct welds

Burn traces have appeared on

the

workpiece and the sanding belt

during

the sanding process

The grain size employed is too fine to

achieve the desired depth of cut

Use a sanding belt with a coarser

grain size or, decrease the depth of cut

The sanding belt is blunt or covered in

a layer of fine dust

Hook a new sanding belt around

11.4.3 Sanding imperfections

Faults

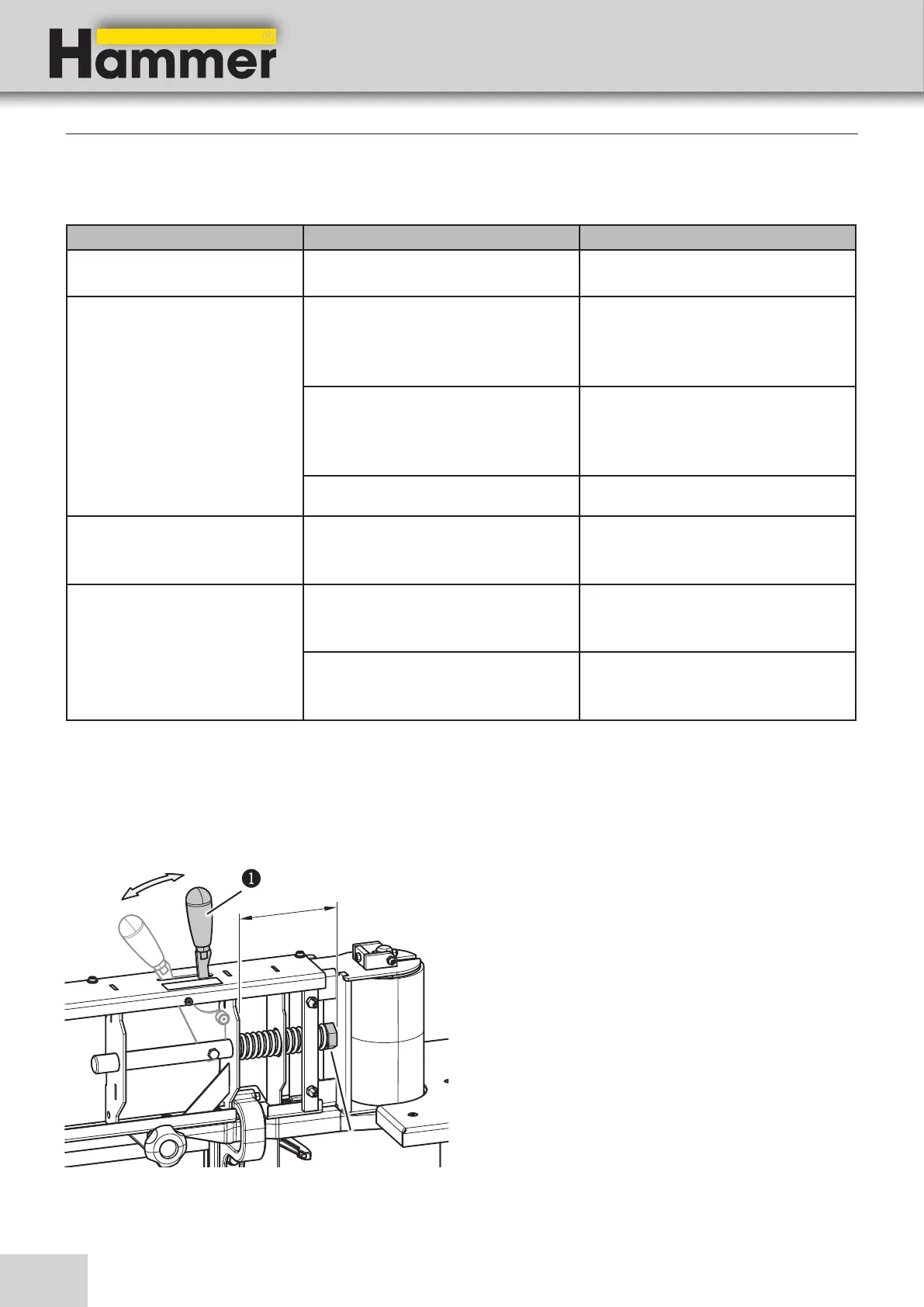

1. Remove the workpiece stop.

2. Remove the rear abrasive belt cover.

3. Tilt the lever until it snaps into place

4. Remove the sanding belt by twisting it slightly while

pulling it out.

5. Measure the distance X.

6. Adjust the distance: 128 mm

7. To adjust the distance, turn the nut.

8. To reassemble, follow the instructions in the reverse

order.

! Lever

" Nut

11.5 Set the spring tension - belt tension

Fig. 11-1: Set the spring tension

Loading...

Loading...