41

Edge sanders

HS 950

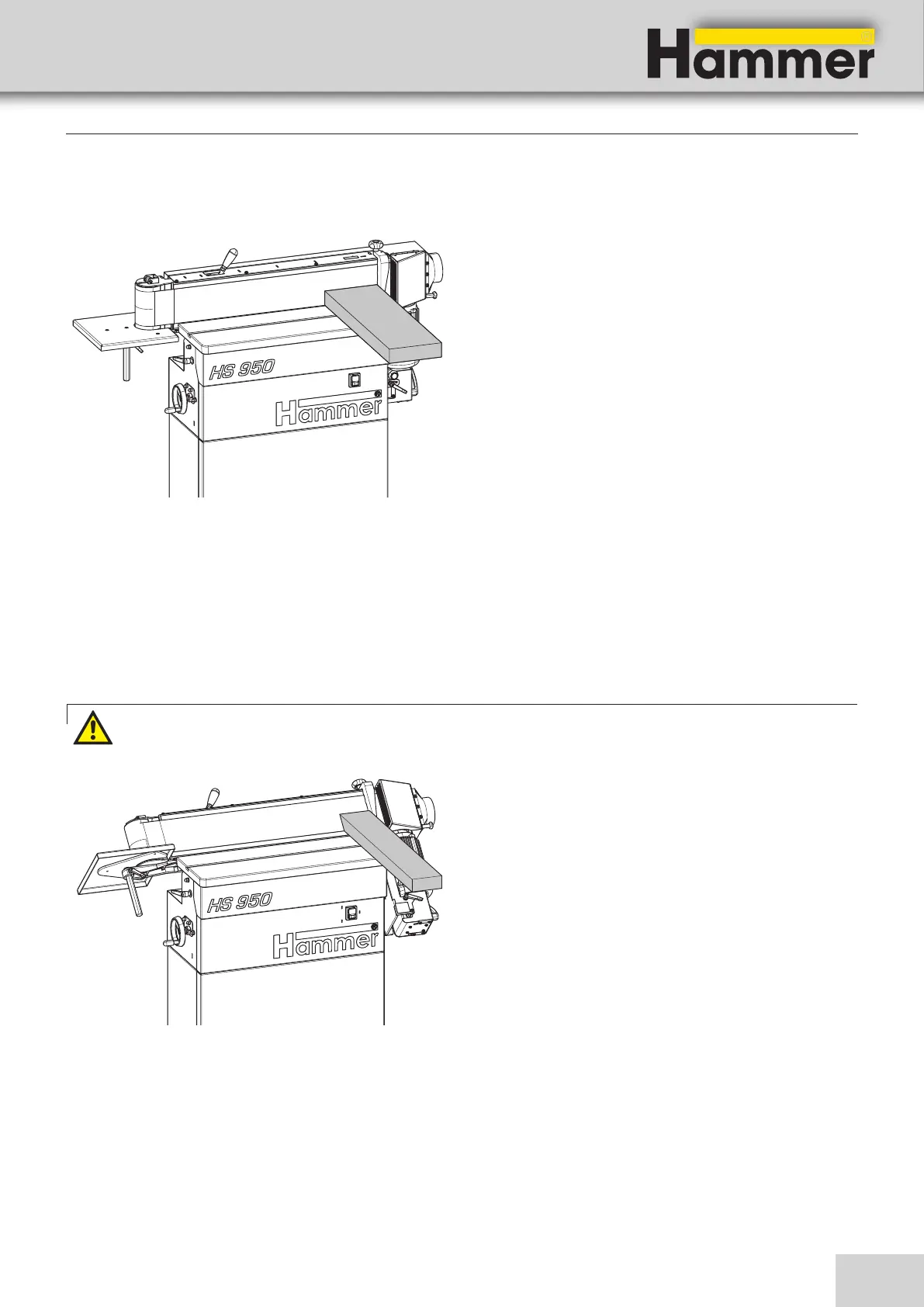

9.4.5 Sanding with tilted unit

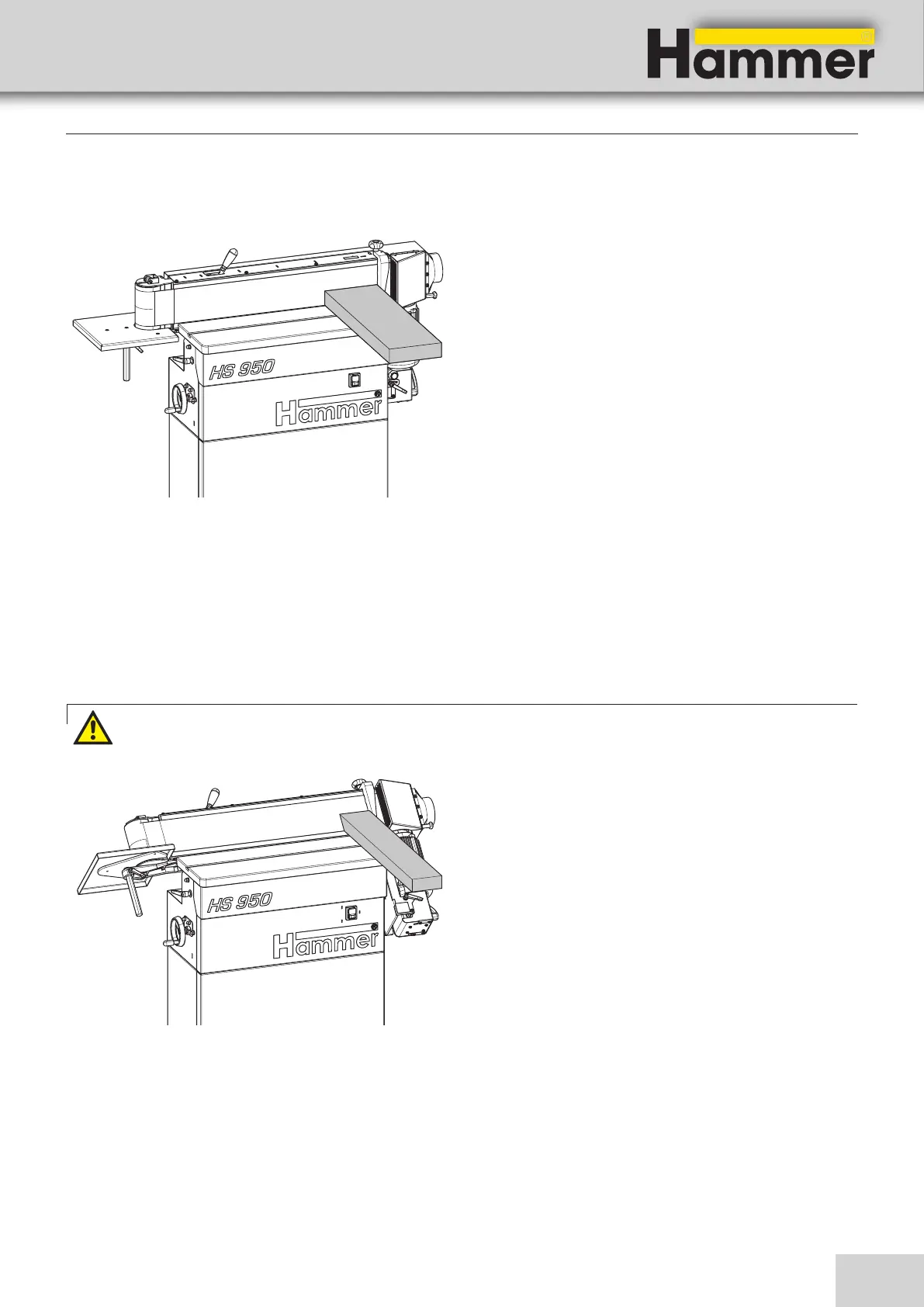

9.4.4 Grinding at the front of the machine

The following operations can be carried out:

• Sanding of parts of drawers

• Straightening corners

• Correcting uneven areas (step between crosspiece

and jamb of a window)

• Head sanding

1. Take note of general procedures for authorized

working techniques.

2. Adjust the table height to the workpiece to be ma-

chined.

3. Check that all clamping levers are tightened firmly.

4. Switch machine on. First place the workpiece against

the fence and then guide it to the abrasive belt. Car-

ry out machining until the surface has been sanded

cleanly.

The tilting sanding unit can be swivelled from 0-90°.

• The sanding of mitered edges

• The chamfering of sharp edges

• The sanding of chamfered edges

1. Take note of general procedures for authorized

working techniques.

2. Adjust the grinding angle by tilting the grinding

unit. Adjust the table height to the workpiece to be

machined.

3. Check that all clamping levers are tightened firmly.

4. Switch machine on.First place the workpiece against

the fence and then guide it to the abrasive belt. Car-

ry out machining until the surface has been sanded

cleanly.

Attention! Risk of material damage! Prior tilting: Remove tools and stops from the work bench

Operation

Fig. 9-4: Grinding at the front of the machine

Fig. 9-5: Sanding with tilted unit

Loading...

Loading...