Operation indicator mode is displayed when the power is ON and it indicates process

value and set value, process value and volume of output, and remaining time of the

corresponding segment when in operation.

Model NP 100 program temperature controller is divided into operation indicator mode and

program mode and this program mode is further divided into engineering group and program group.

Operation

Indicator Mode

Engineering

Group

Program Group

Engineering mode sets up the basic functions of the instrument including types of

input and output, communication, retransmission, alarm, controlling movement, PID,

and auto tuning.

Program mode sets up the control program. It establishes the number of program

repetition, pattern number, segment number setup, program start condition, time sig-

nal, program ending mode, and each segment

s parameter.

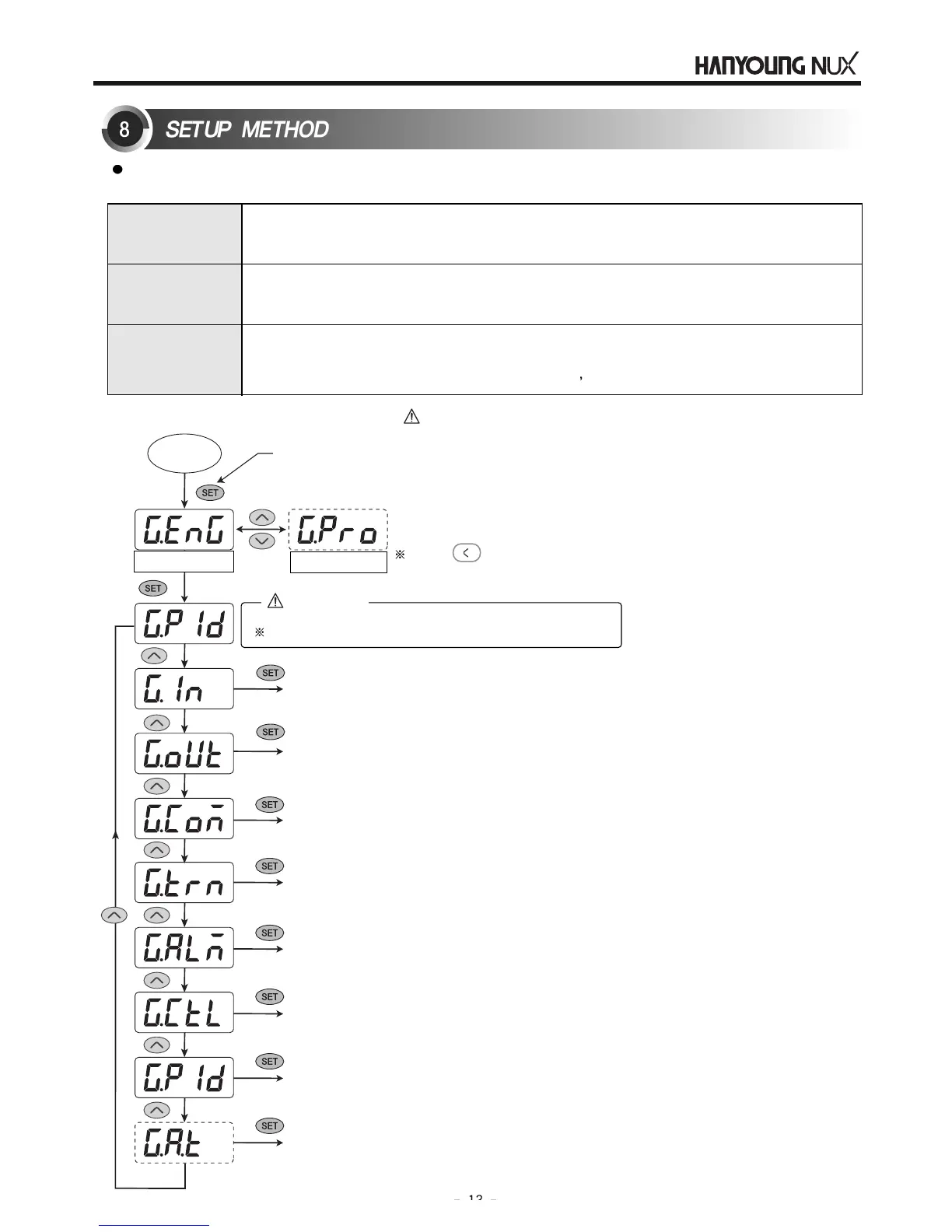

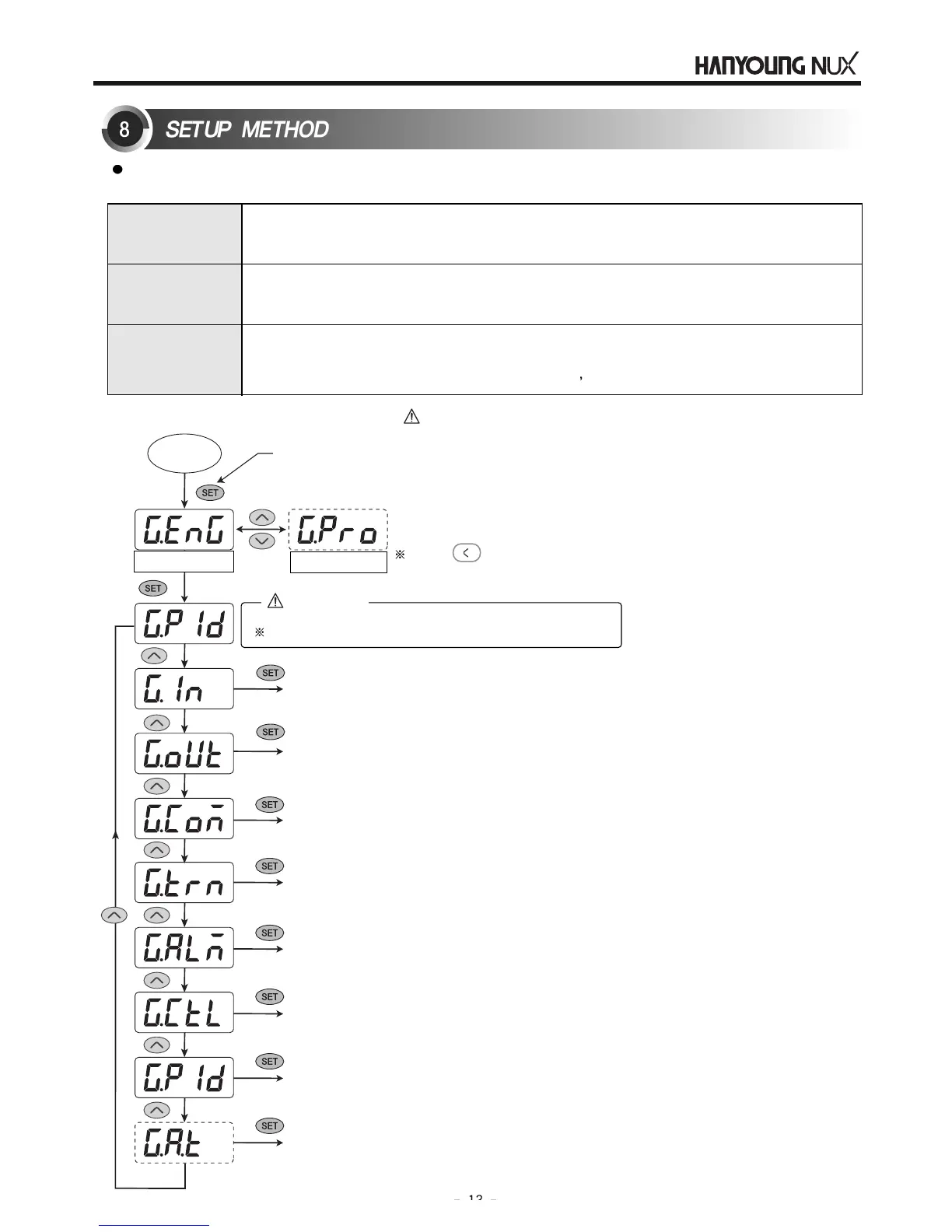

8-1. Engineering Group Setup

Power

ON

(Press 2.5

second.)

Must start with the setup of the input and output.

Engineering group

Caution

Program group

(1.Input setup group) (refer to page 14)

8-1-1

8-1-2

8-1-3

8-1-4

8-1-5

8-1-6

8-1-7

8-1-8

(2.Output setup group) (refer to page 15)

(3.Communication setup group) (refer to page 16)

(4.Retransmission setup group) (refer to page 17)

(5.Alarm setup group) (refer to page 18)

(6.Control setup group) (refer to page 19)

(7.PID setup group) (refer to page 20)

(8.Auto tuning setup group) (refer to page 21)

Press button to enter the engineering

mode from each setup group

- Preparation must be carried out in engineering mode when

operating the controller.

- There are set up mode for input and output functions and set

up mode for control function in engineering mode but must

start with the setup of the input and output functions.

Caution

Loading...

Loading...