8 - Technical Specifications

151

Specifications

Diaphragm pumps

Tractor Requirements

Power Take-off

Hydraulic System

* Depending on scope of supply.

€

DANGER! If one or more the values are exceeded, this may cause damages and sudden leaks on the sprayer. Risk of

injuries and fatal accidents.

Hydraulic Oil

Oil from the tractor to the sprayer must have been filtered according to ISO 4406 20/14 as a minimum. Particles bigger than

25 micron in size must be filtered from the oil (Filtration quotient ß25-75, ISO 4572-81 Multipass test).

• Follow the tractor oil change schedule as directed.

• Choose hydraulic oil with anti-foam and anti-oxidant additives.

Be especially cautious where the tractor transmission oil is also used for the sprayer hydraulics. Consult the tractor dealer if

in doubt.

Pump model 464/6.5 PSI RPM GPM HP

0 1000 92.2 4.3

220 1000 78.7 13.8

Pump model 464/10.0 PSI RPM GPM HP

0 540 74.0 2.4

220 540 68.4 11.1

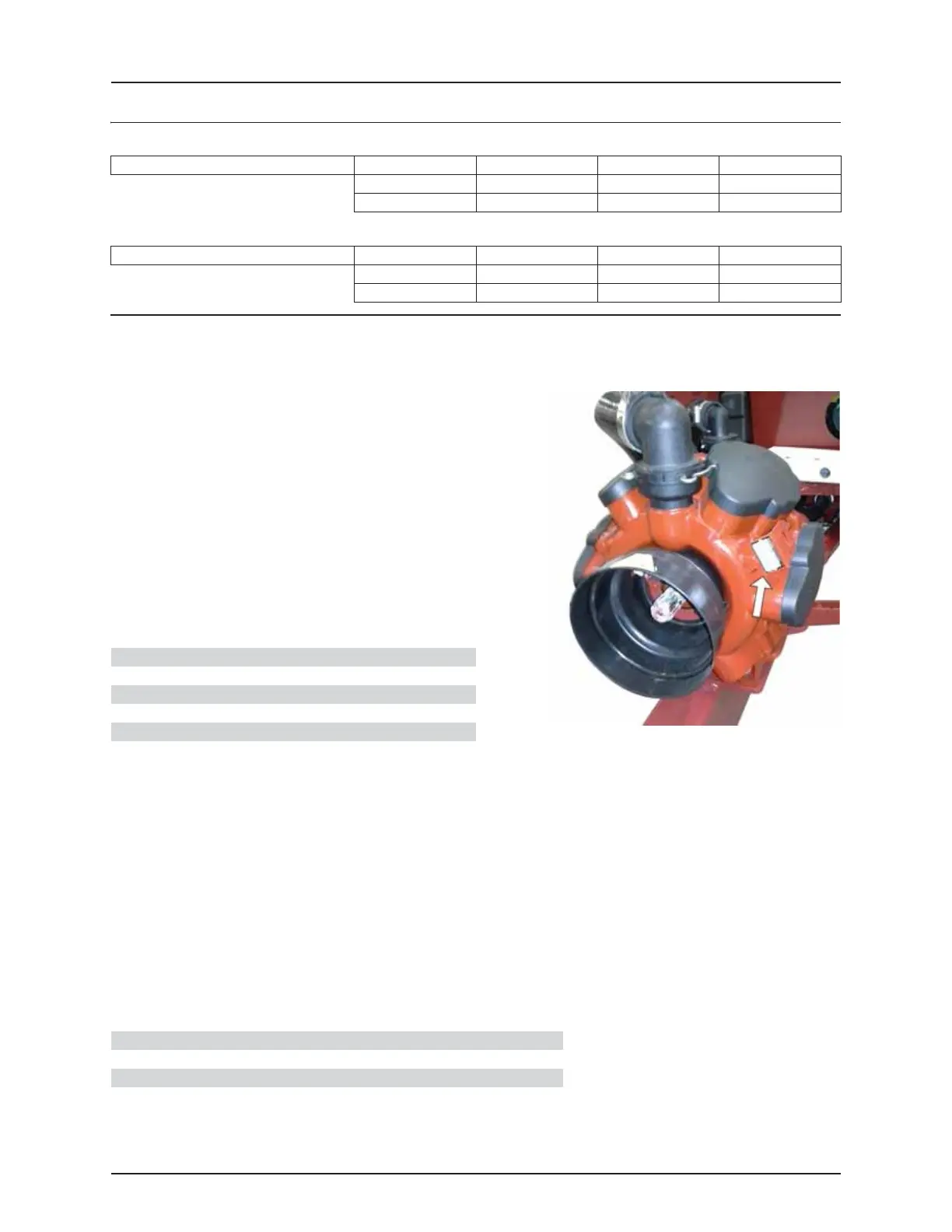

Min. / Max. operating torque (kW): See type sign for liquid pump.

The type sign is located on the front

side of the pump facing towards the

tractor.

Max. operating temperature 176° F (80° C)

Max. operating pressure from the tractor 3050 psi (210 bar)

Min. operating pressure from the tractor 2610 psi (180 bar)

Max. flow from tractor 32 gal/min (120 l/min)

Min. flow from tractor @ 2900 psi (200 bar) 4 - 21 gal/min (15 - 80 l/min)*

Max. oil filter rating 10 μm

Type Hydraulic oil with anti-foam and antioxidant additives.

Purity ISO 4406 20/14. Filtration quotient ß25-75, ISO 4572-81.

Multipass test 25 micron absolute.

Viscosity Minimum: 10 mm²/s (cSt).

Maximum:100 mm²/s (cSt).

At normal operation:15 - 35 mm²/s (cSt).

Loading...

Loading...