6 - Maintenance

96

Grease Nipple

When lubricating the sprayer, please use a greasing gun which fits the

dimensions of the grease nipples.

ATTENTION! If grease is leaking from the nipple near its threaded

part when grease is being applied, tighten the nipple by using a

wrench or socket. Replace the nipple if it is damaged or bent out

of shape.

ATTENTION! If applying grease into the nipple seems difficult,

unscrew the nipple. Check if the nipple is blocked inside, or if the

spring-loaded ball is stuck. Clean or repair as needed.

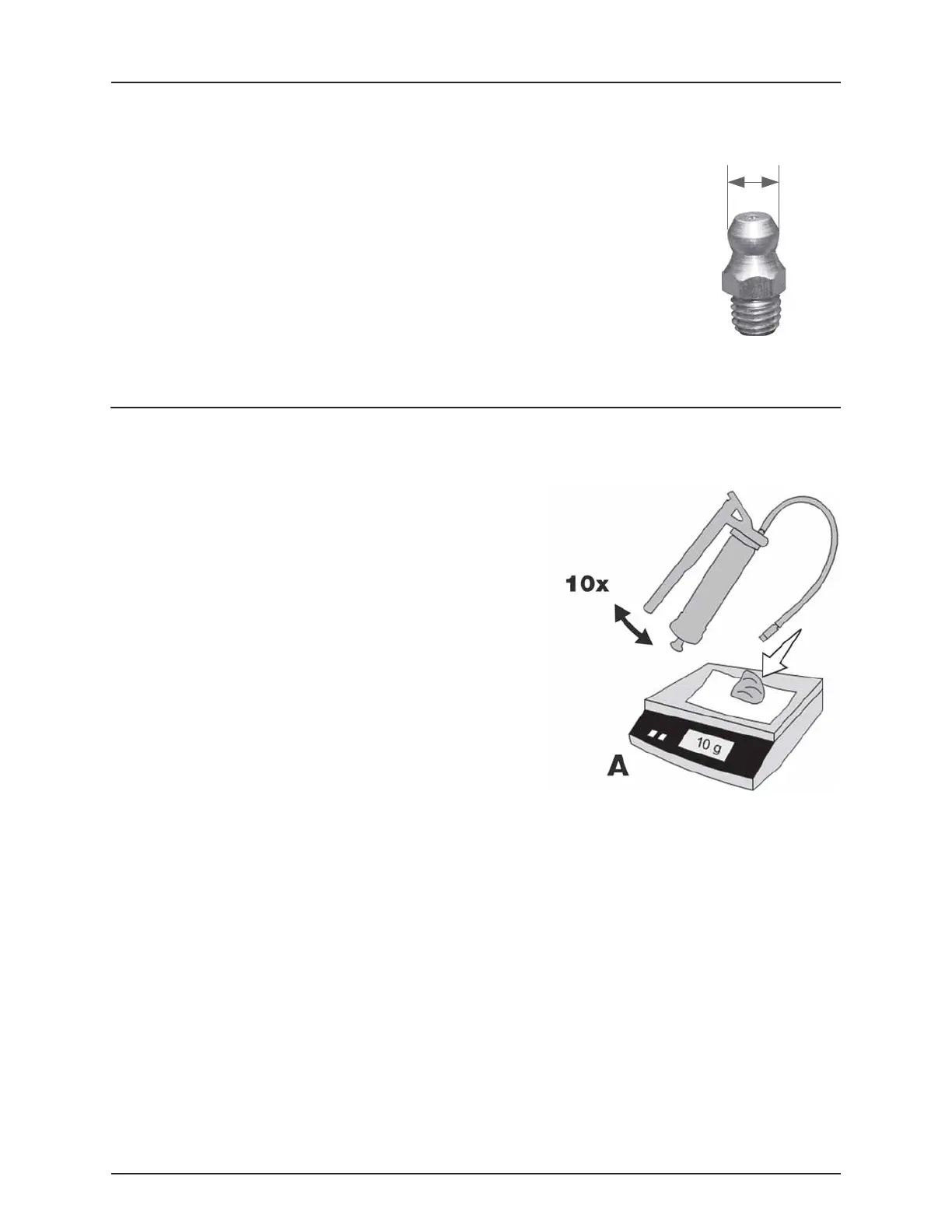

Grease Gun Calibration

Before lubricating the sprayer, you must calibrate your grease gun to ensure that the correct amount of grease is applied to

each lubrication point. The correct amount of grease applied will prolong the lifetime of the sprayer.

Calibration Example

1. Insert the correct grease cartridge in your grease gun.

2. Apply grease onto a tissue or a piece of paper. Complete 10 full

strokes of the grease gun.

3. Place the paper with grease on a scale (A).

4. If your grease pile weighs e. g. 10 grams (0.4 oz.), then 1 stroke

equals 1 gram (0.04 oz.) of grease.

When calibrated, you can count how many strokes to complete when

lubricating the different grease points on the sprayer according to the

specifications.

Alternative Method

1. Count the strokes, until you have 10 grams (0.4 oz) of grease piled

up on the scale (A).

2. Now you can figure out how many strokes to use for applying a

certain amount of grease to a lubrication point.

Nipple head type: DIN 71412

Nipple head size (A): 6.5 mm

Loading...

Loading...