3 - Description

3.3

ATTENTION! Only the function in use should be open - always close valve when function is no longer needed.

ATTENTION! If a MANIFOLD valve is too tight to operate - or too loose (= liquid leakage) - the valve needs to be

serviced. Please see the “Maintenance” section for further information.

The MANIFOLD valve is equipped with symbol decals located on the disc for easy identification and operation. A function

is activated by turning the handle towards the desired function symbol.

Valves and symbols

HC/1 or HC/2 Hydraulic control

Liquid system

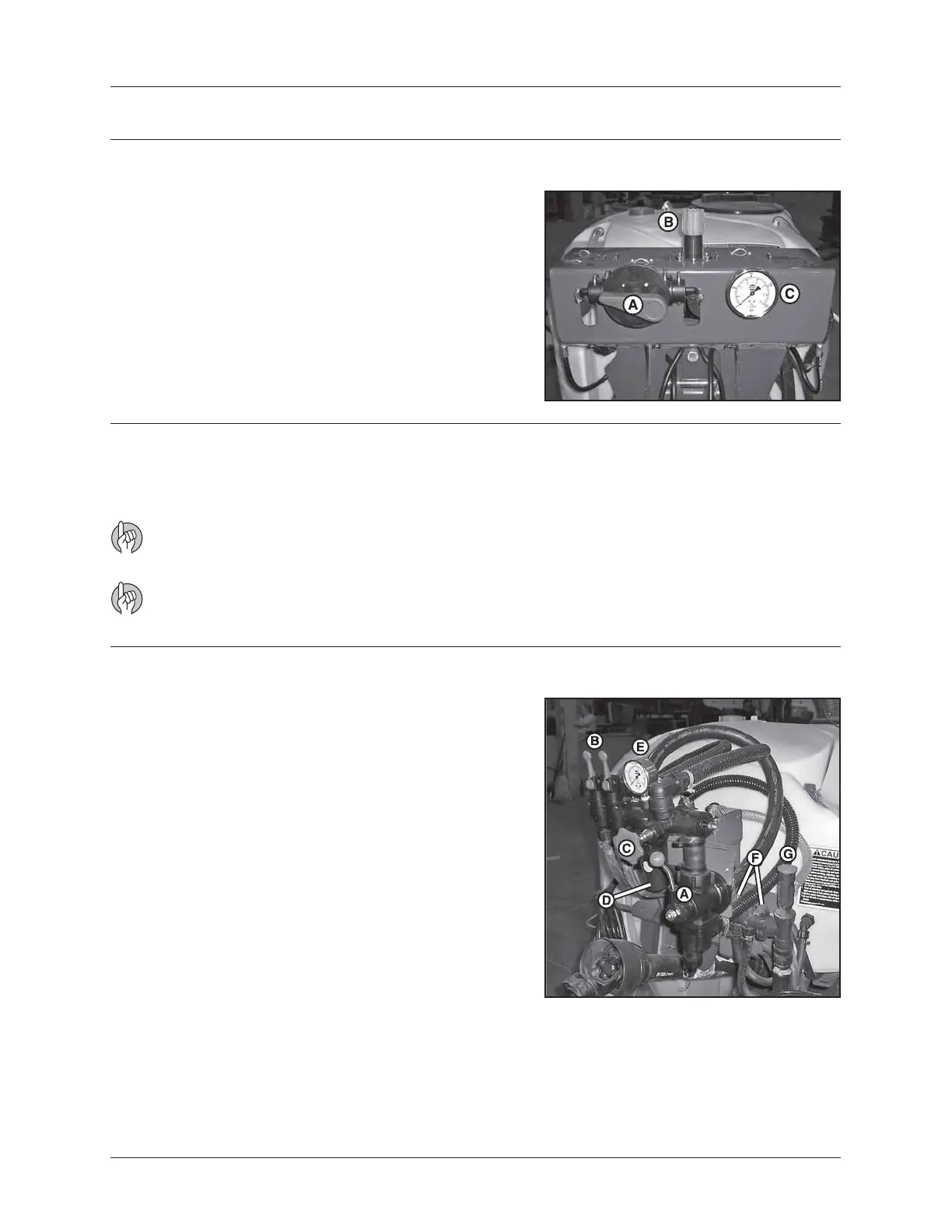

The HC/1 or HC/2 hydraulic control consists of a MANIFOLD valve (A)

for operating agitation and the powder mixer, a manual pressure

regulator (B) with built-in safety valve, and a manifold pressure

gauge (C). The blower nozzles are operated with hydraulically con-

trolled section valves using the tractor hydraulics. All of these con-

trols are conveniently mounted in the control bracket located on the

front of the sprayer.

BK/2 Manual control

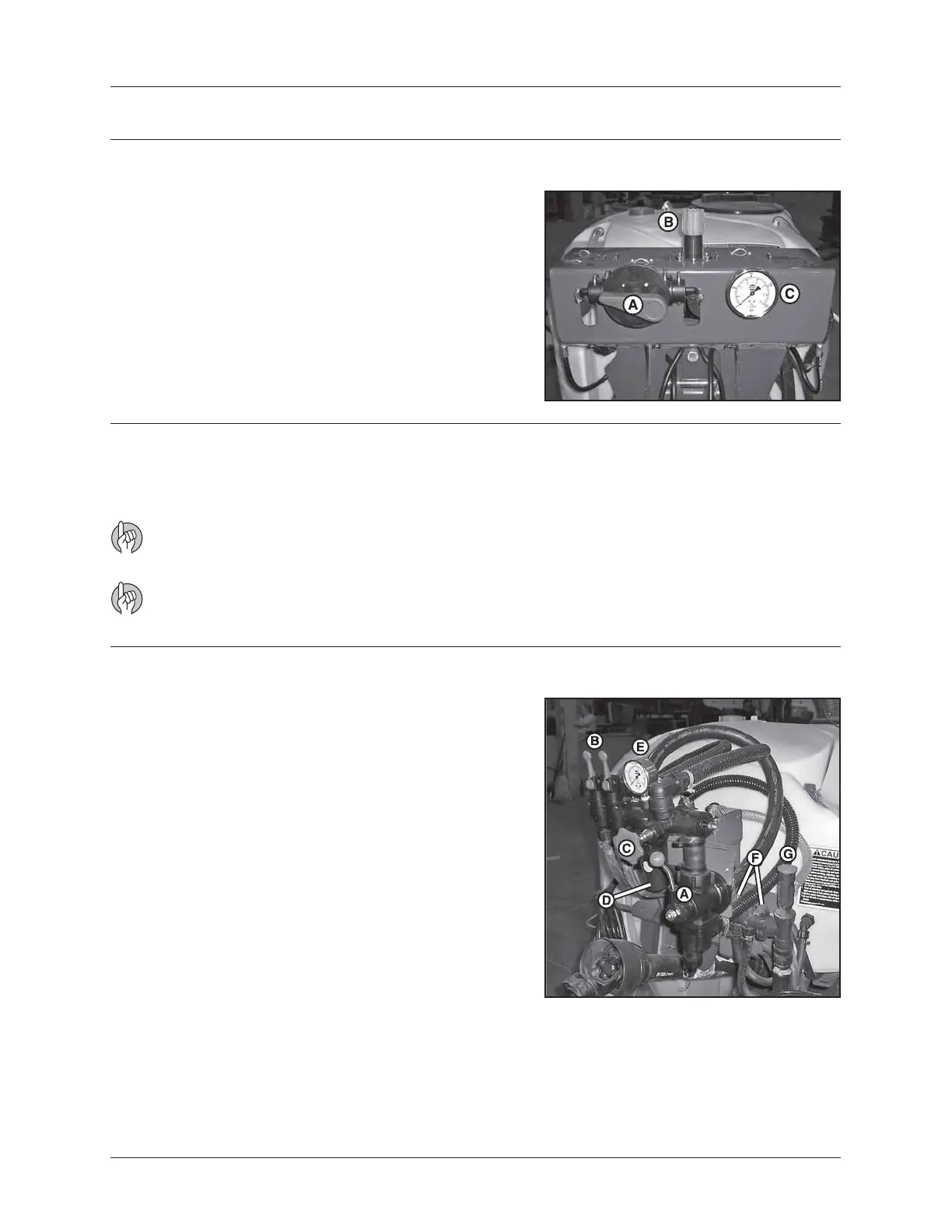

The BK/2 manual control consists of a Master On/Off valve (A), blow-

er nozzle distribution valves (B) with pressure equalization, manual

pressure adjustment valve (C), pressure filter (D), 2-1/2” pressure

gauge (E) and HARDI-MATIC. The HARDI-MATIC is a mechanical rate

controller that ensures a constant volume of spray solution per acre

at varying speeds in the same gear.

Agitation and the powder mixer are operated with the distribution

valves (F) located next to the safety valve (G).

Loading...

Loading...