5 - Operation

5.5

When working with the liquid circuit only, it is not necessary for the

fan to be on. Therefore, it is advisable to put the gear box in the neu-

tral (off ) position.

The gear box is behind the pump. When the gear lever (A) is in the

middle position, the gear box is in neutral.

If you cannot get the gearbox into gear because of interference

between the teeth and sprockets, engage the PTO for a few seconds

and try again.

Gear Box

WARNING! Both the pump and fan should be at a complete

stop before attempting to change gears in the gear box.

The maximum number of revolutions when in use is 540 rpm. The

diaphragm pump is self-priming and can be run dry without dam-

age.

Diaphragm pump

ATTENTION! See “Maintenance” section for how frequently the

pump needs to be checked.

WARNING! Make sure the pump is properly greased before

operating the sprayer.

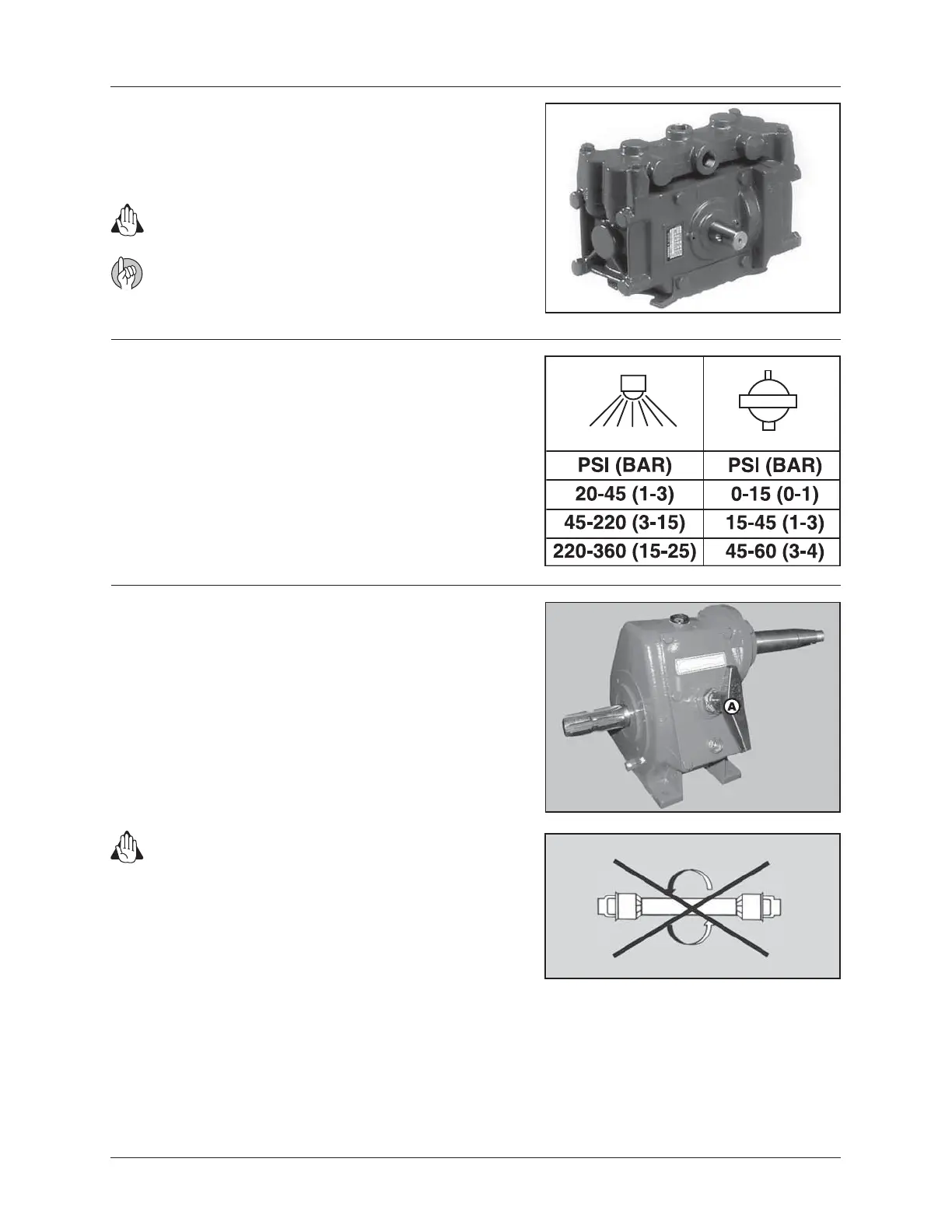

The air pressure in the damper on the HARDI® diaphragm pump is

factory preset at 30 psi (2 bar). This is suitable for nozzle spray pres-

sures between 45 and 220 psi (3 and 15 bar). If different nozzle pres-

sures are required, set pressure damper at pressures indicated.

Pressure damper adjustment

Loading...

Loading...