4.1

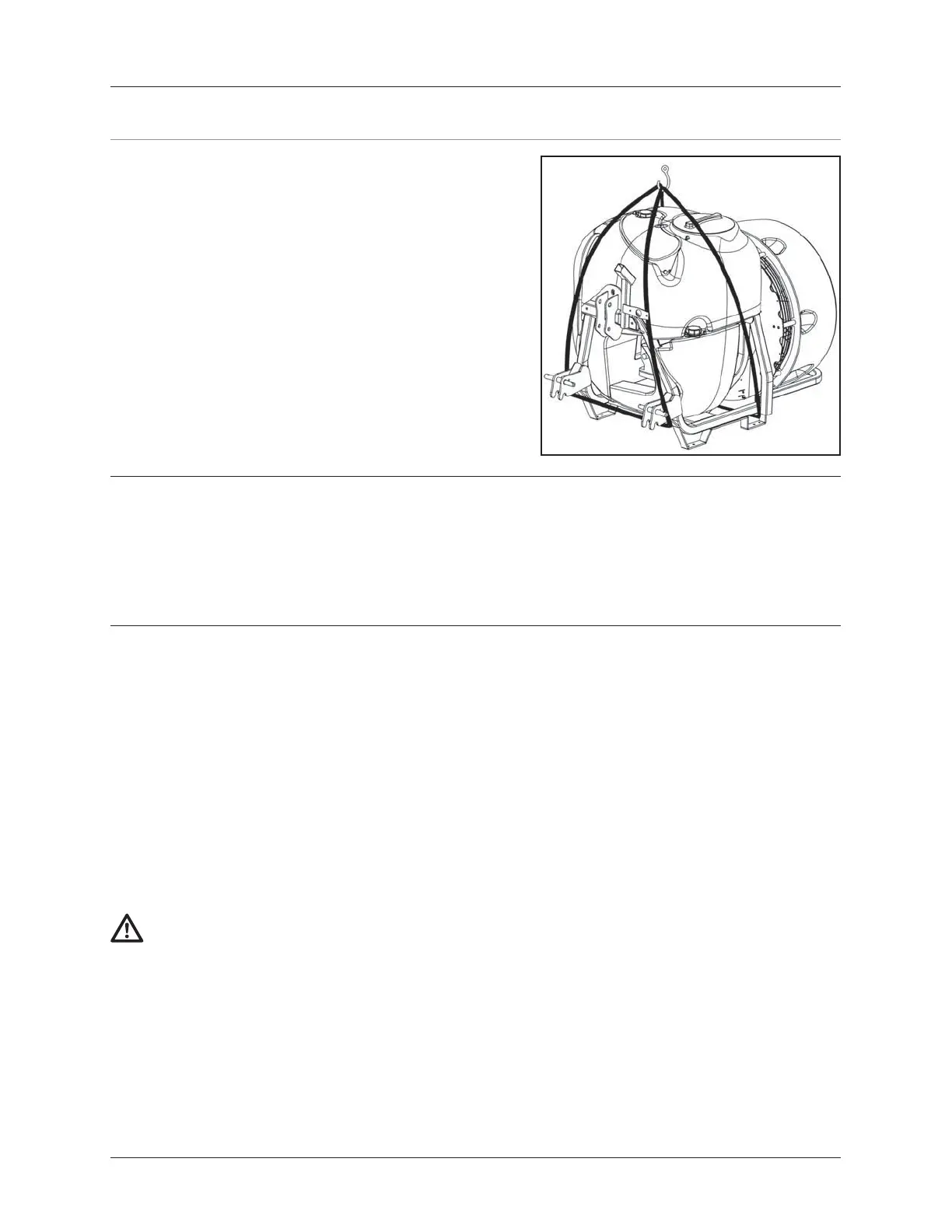

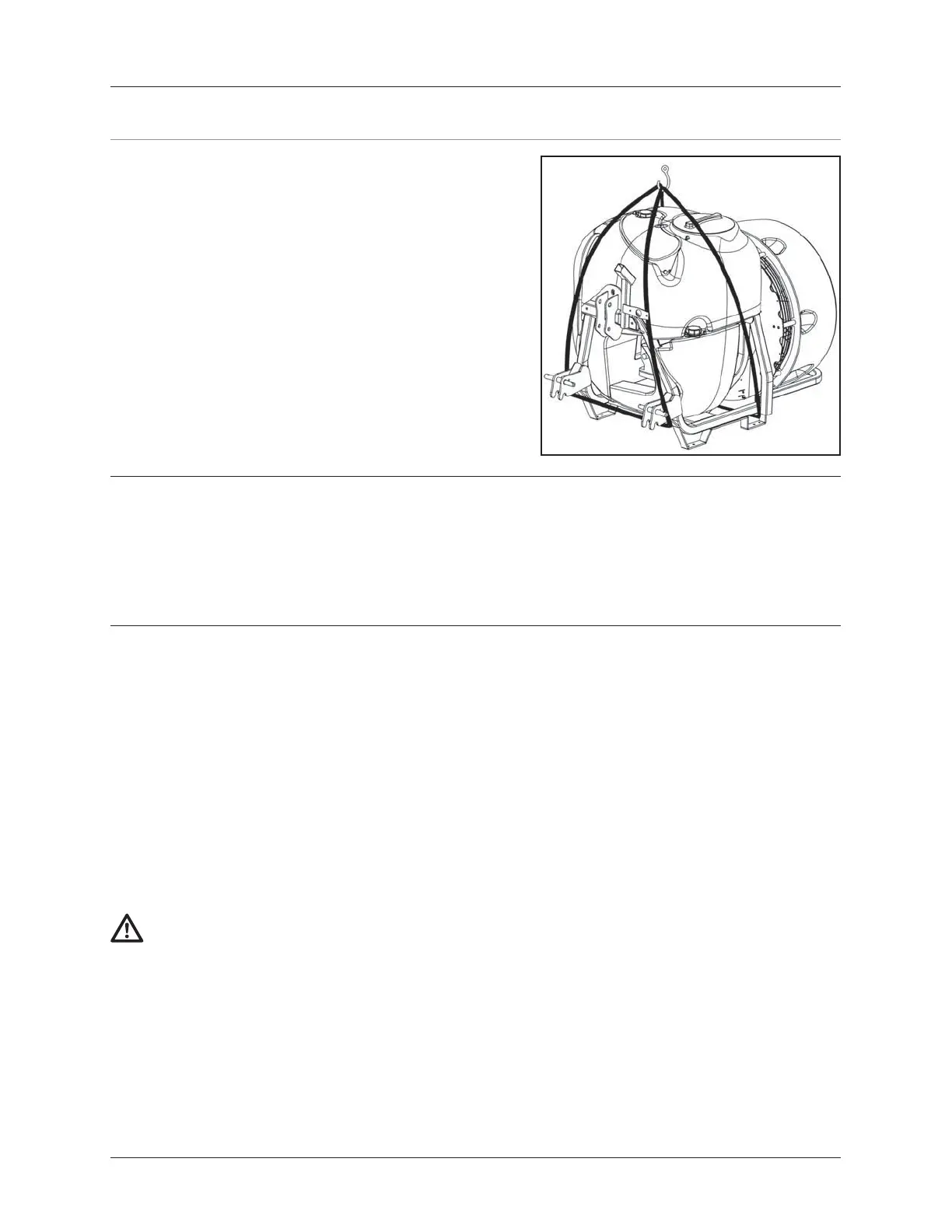

When unloading with an overhead lifting device, please observe the

lifting points as shown in the picture, and make sure that the straps

or belts used for lifting are strong enough.

If using a forklift, be careful not to damage the fittings at the bottom

of the tank.

Unloading the sprayer from the truck

General info

4 - Sprayer setup

Although the sprayer has been applied with a strong and protective surface treatment on steel parts, bolts etc. in the fac-

tory, it is recommended to apply a film of anticorrosion oil (e.g. CASTROL RUSTILLO or SHELL ENSIS FLUID) on all metal

parts in order to avoid chemicals and fertilizers discoloring the enamel. If this is done before the sprayer is put into opera-

tion for the first time, it will always be easy to clean the sprayer and keep the enamel clean for many years. This treatment

should be carried out every time the protection film is washed off.

Before putting the sprayer into operation

DANGER! ROTATING TRANSMISSION SHAFTS WITHOUT PROTECTION GUARDS ARE FATAL.

1. Always STOP ENGINE before attaching the transmission shaft to tractor P.T.O. - most tractor P.T.O. shafts can be rotated

by hand to facilitate spline alignment, when engine is stopped.

2. When attaching the shaft, make sure that the snap lock is FULLY ENGAGED - push and pull shaft until it locks.

3. Always keep protection guards and chains intact and make sure that it covers all rotating parts, including CV-joints at

each end of the shaft. Do not use without protection guard.

4. Do not touch or stand on the transmission shaft when it is rotating - safety distance: 5’ (1.5 meter).

5. Prevent protection guards from rotating by attaching the chains allowing sufficient slack for turns.

6. Make sure that protection guards around tractor P.T.O. and implement shaft are intact.

7. Always STOP ENGINE and remove the ignition key before carrying out maintenance or repairs to the transmission shaft

or implement.

Transmission shaft - Operator’s safety

Loading...

Loading...