6 - Maintenance

6.3

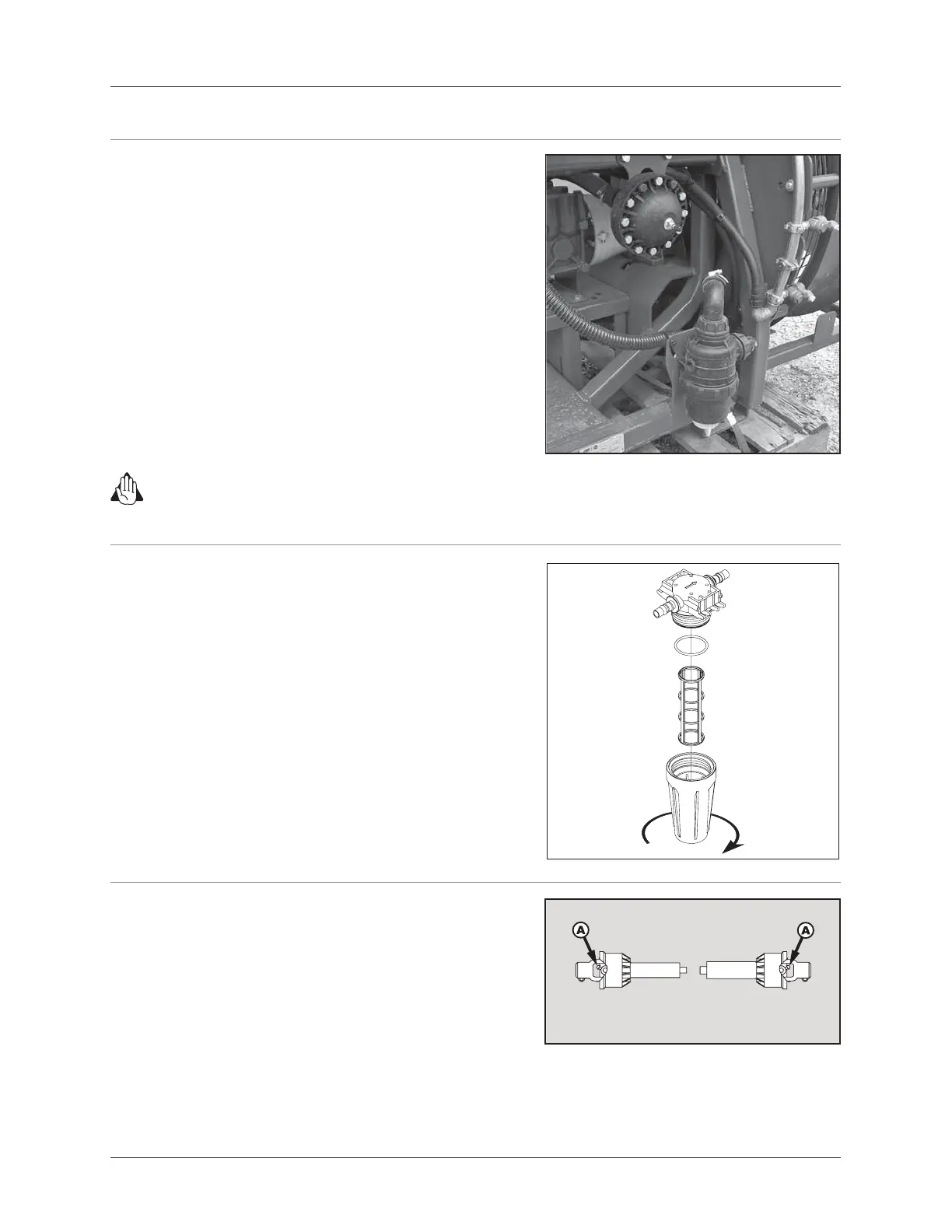

The suction filter is located on the left side of the sprayer near the

pump. Its primary purpose is to protect the pump from damage. It

contains an automatic shut off valve to allow the operator to clean

and service the filter with a full tank.

Turn the yellow handle counter-clockwise until it “pops out”. This

closes an internal valve to prevent the main tank from draining

when cleaning the filter. Unscrew the large plastic nut and remove

the lid. Remove the filter for cleaning, being very careful not to dam-

age the O-ring of the filter lid. This would allow air to enter during

suction and cause rattling of hoses and continual pressure varia-

tions. To prevent this, it is advisable to lubricate the O-ring with veg-

etable oil before closing the lid. Finally, replace the yellow valve han-

dle and lock into position to allow flow through the filter.

10 hours service - Suction filter

Regular maintenance

WARNING! The suction filter is one of the most important elements of the fluid circuit. The ability of the pump to

take in air correctly largely depends on how well the filter has been cleaned and maintained. It is necessary to

clean the filter after every working day in order to keep the filter free of blockage.

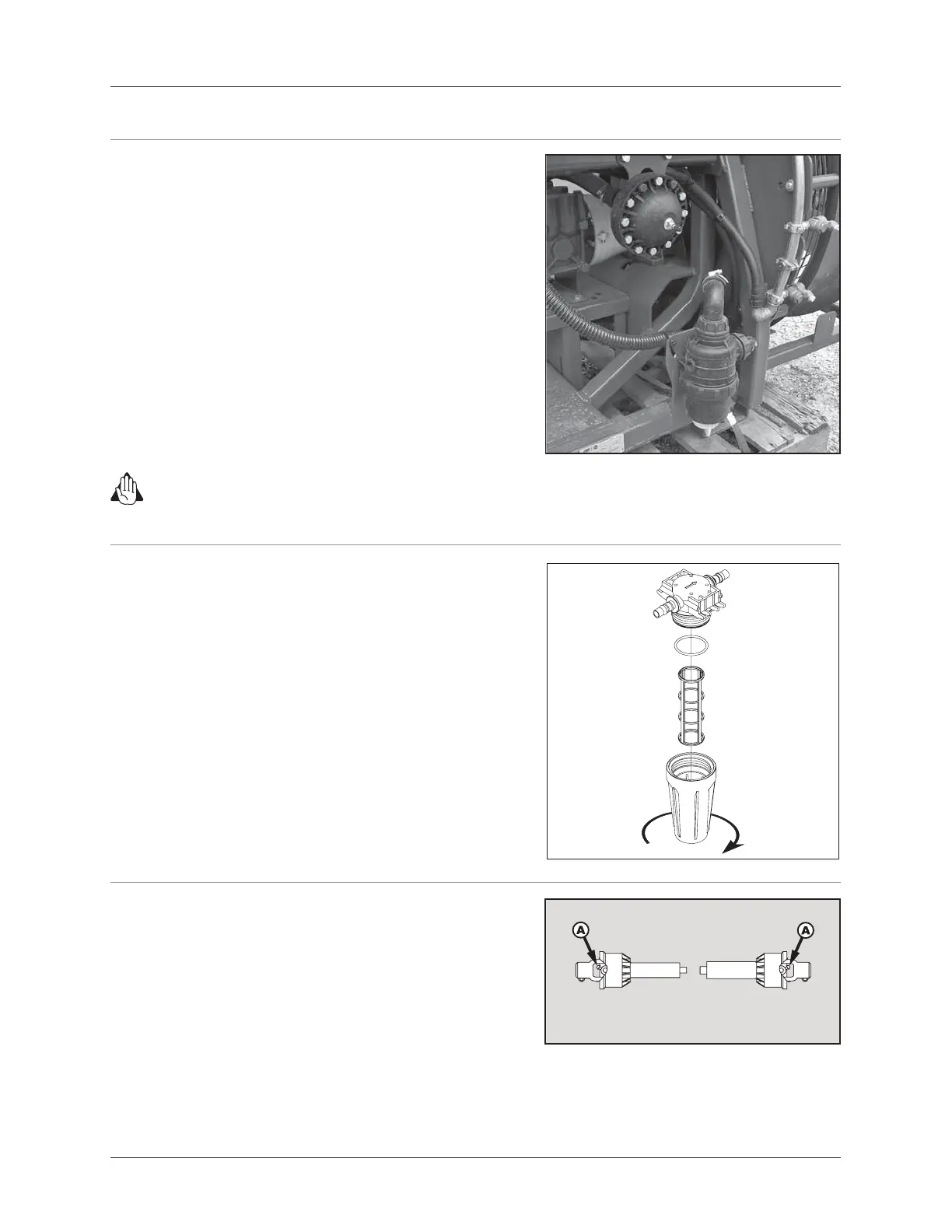

Unscrew the filter bowl to inspect and clean the filter. When

reassembling, the O-ring should be lubricated with vegetable oil.

Alternative filter meshes are available. See section on Technical spec-

ifications - Filters and nozzles.

10 hours service - In-Line filter

The universal joints and ball bearings should be lubricated with

grease at the points (A) every 10 hours.

10 hours service - Transmission shaft

Loading...

Loading...