6 - Maintenance

6.7

The maintenance and replacement intervals for the following will depend very much on the conditions under which the

sprayer will be operated and are therefore impossible to specify.

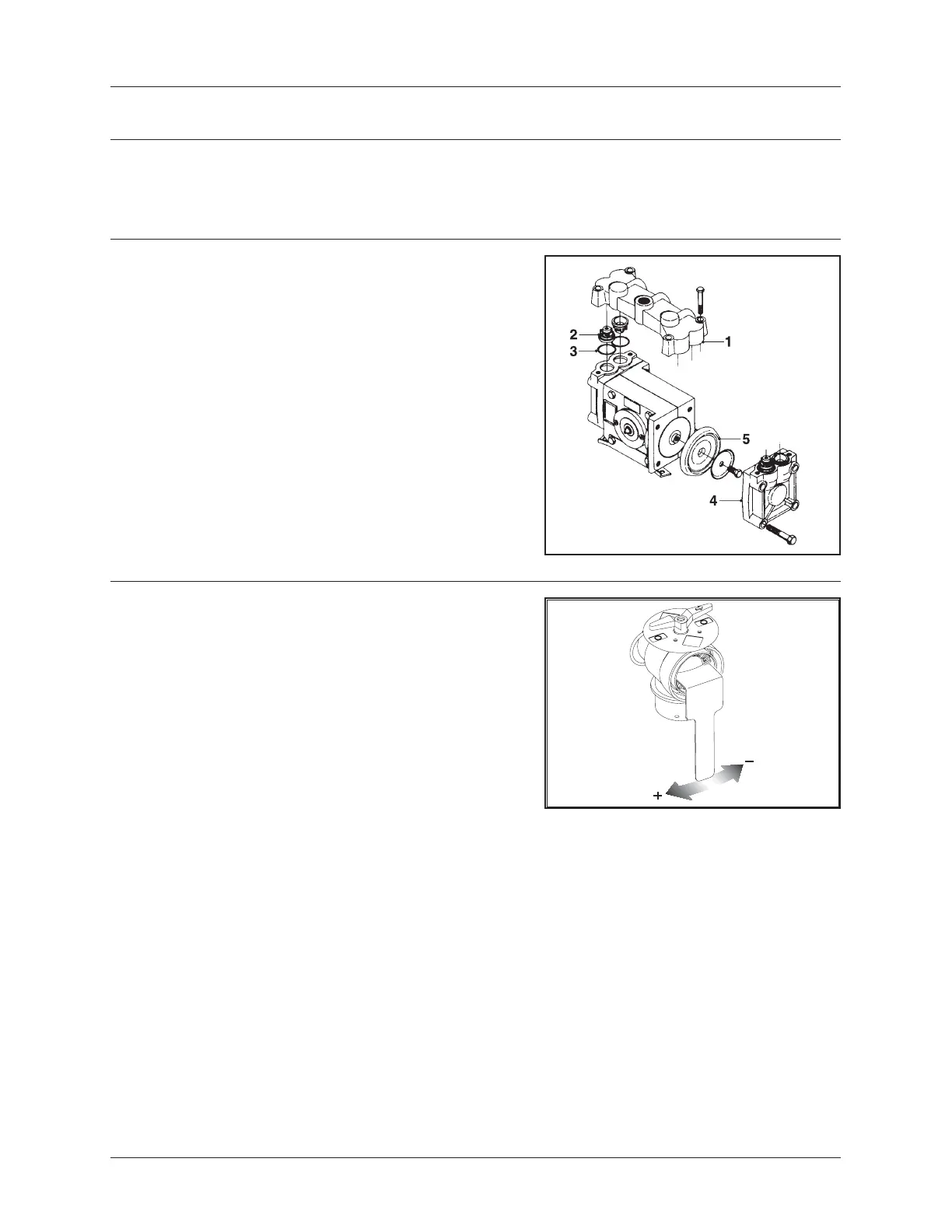

Model 321 pumps:

Valves

Remove valve compartment (1). Before changing the valves (2) -

note their orientation so they are replaced correctly. It is recom-

mended to use new gaskets (3) when changing or checking valves.

Diaphragms

Remove the diaphragm cover (4) after having dismantled the valve

compartment as indicated above. The diaphragm (5) may then be

changed. If fluids have reached the crankcase, re-grease the pump

thoroughly.

Pump valves and diaphragms replacement

General info

Occasional maintenance

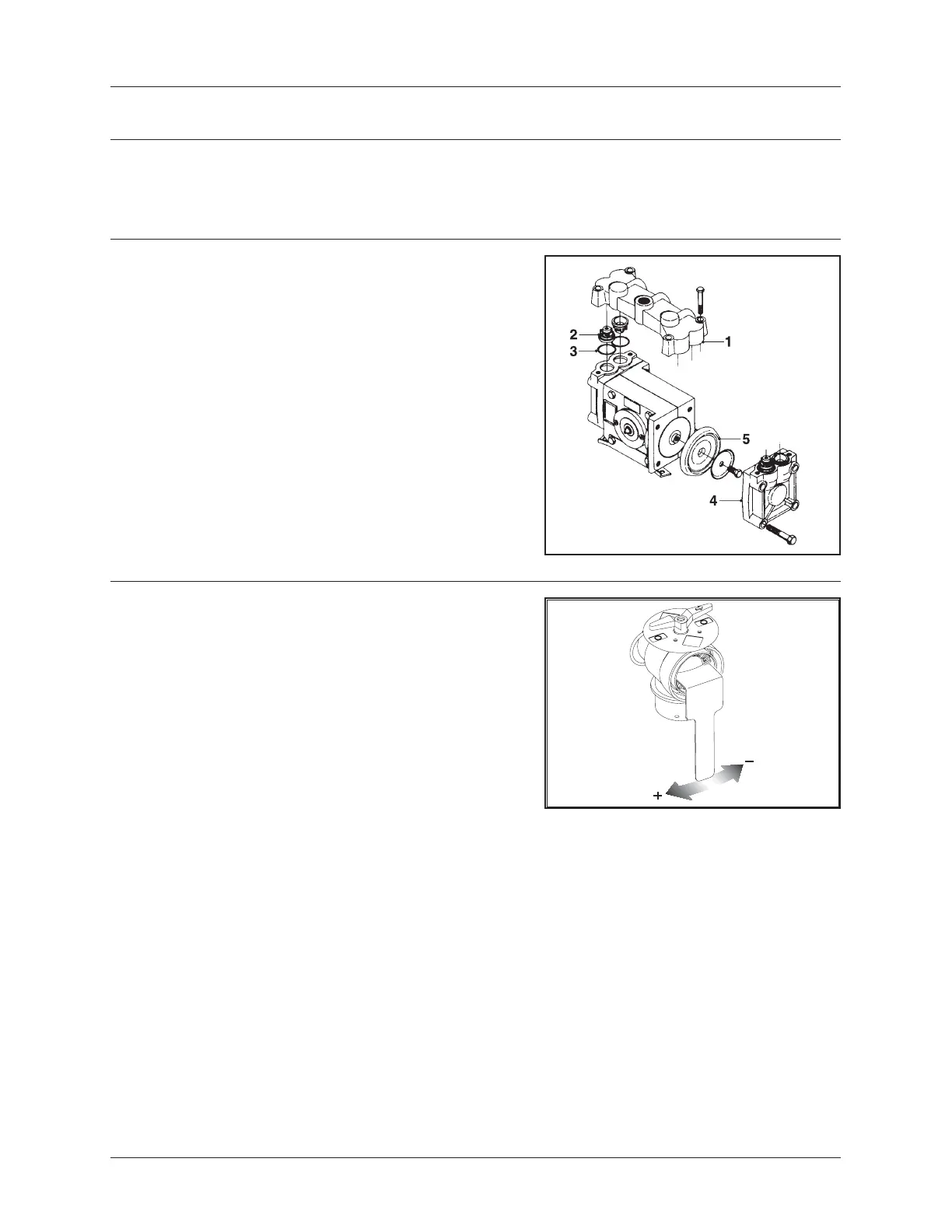

The MANIFOLD valve can be adjusted if it is too tight to operate - or

if it is too loose (=liquid leakage). Correct setting is when the valve

can be operated smoothly by one hand. Use a suitable tool and

adjust the toothed ring inside the valve as shown on the drawing.

Adjustment of Manifold valve

Loading...

Loading...