5 - Operation

5.6

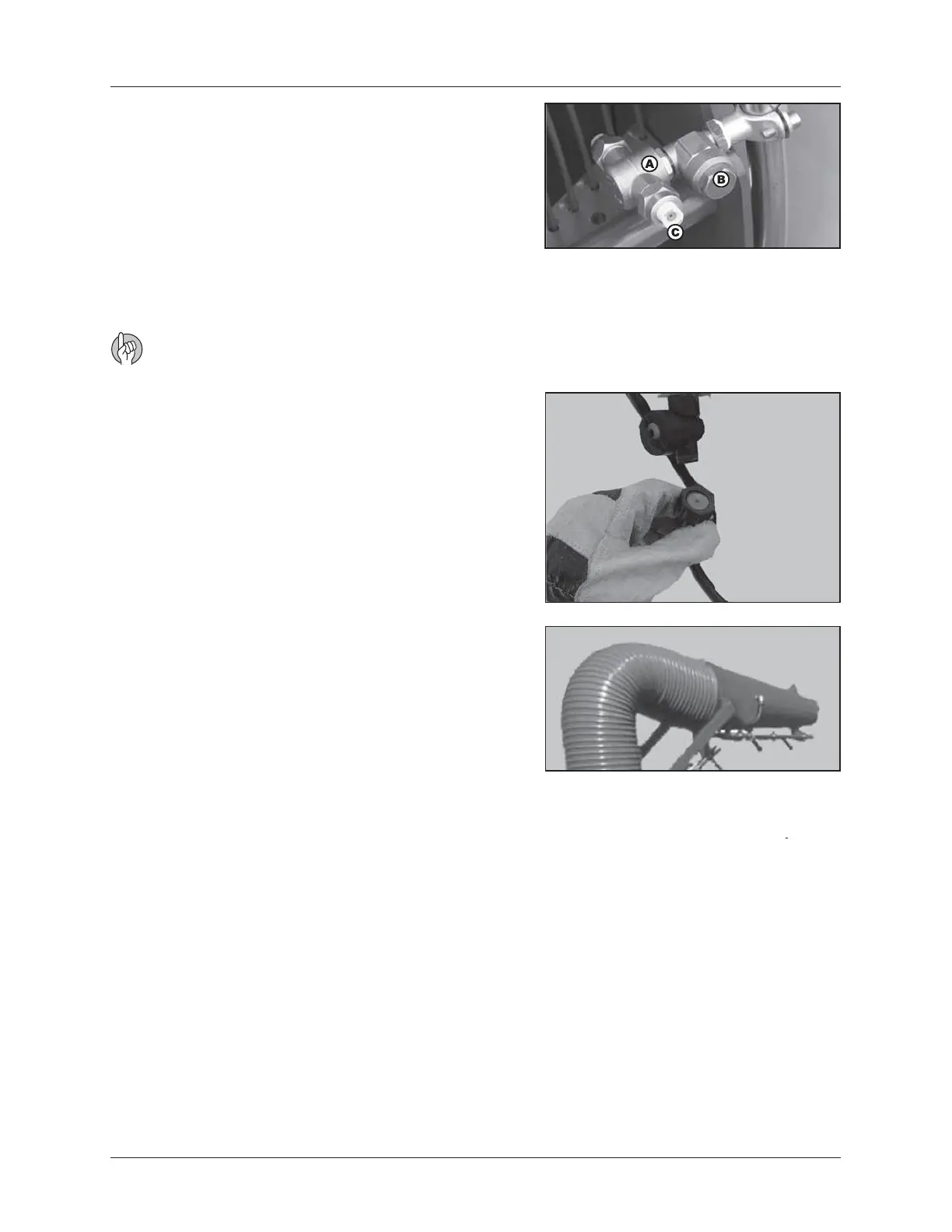

The standard nozzle holders included in axial air kits are made of

brass (A). They can be closed individually by turning them 90°. When

open, they have a range of +/- 15° to vary their inclination. They are

fitted with a non-drip valve (B) to avoid the loss of chemical product

that remains in the lines when the different sections are shut off.

The nozzles (C) are turbulence (also known as ATR) nozzles. They are

color-coded and their pressure ranges from 70 to 215 PSI (5 to 15

bar).

This type of nozzle can also be used with hydro-pneumatic equip-

ment.

Nozzles

ATTENTION! It is not advisable to go over 215 PSI (15 bar) with ATR nozzles as the drops would be far too small and

the product could evaporate in high temperatures or be carried off by the breeze or wind.

The pneumatic system is fitted with ceramic calibrated discs. This

type of disc has two possible positions. If the disc is placed so that

the flow goes in through the cone-shaped side, the nozzle will give

out more flow than if it is placed so that flow goes in through the

flat side.

The function of these nozzles in the pneumatic system is to control

the amount of flow needed to break up the spray film. The pressure

ranges in the pneumatic system range from 0 to 60 PSI (0 to 4 bar).

The CANNON model has a spout made of polyester and is only fitted

on a pneumatic system. It includes 4 bi-jet holders with two nozzles

each. Also included are three adjustable nozzles outside the spout

which allow for proper treating of nearby crops.

Loading...

Loading...