HT# 059299-00 A

• The RS485 cable length must not exceed 3500 feet

• The RS485 cable must use one of the Platinum control’s

enclosure side knockouts Do not use bottom knockouts for

communication cabling

• Connect the RS485 cable coming from the BACnet MSTP or

Modbus network to the Black RS485 communication socket on

the back of the control’s Communication Board The terminals

are labeled ‘A1 (+)’, G1 (Ground), and ‘B1 (-)’

The RS485 Ground terminal (G) MUST be

connected to the BMS RS485 Ground

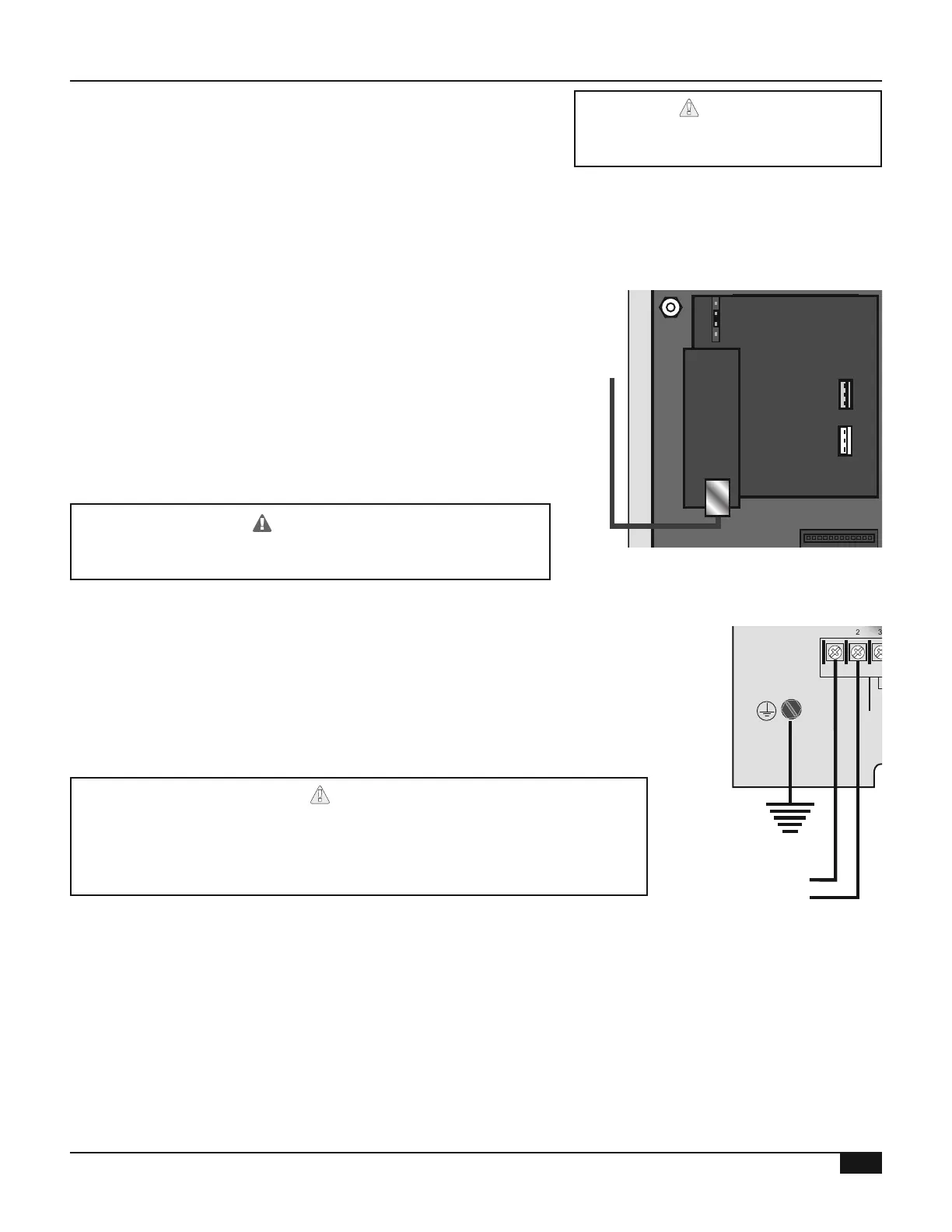

• The Ethernet cable must use one of the Platinum control’s

enclosure side knockouts Do not use bottom knockouts for

communication cabling

• For reliable communication, the maximum Ethernet cable run

must not exceed 200'

• Use only CAT-5E Ethernet cable or better when connecting

from the Internet Modem, router or the IP network to the

Ethernet RJ45 communication socket on the back of the

control’s Communication Board

Class 1 voltage wiring (low voltage) must use a different knockout

and conduit from any Class 2 voltage wiring (high voltage)

N

5V

8V

Ethernet

RS485

Main Board

Control Stages

A & B

Control Stages

C & D

A1

G1

B1

A2

G2

B2

RS485

Communication Board

(HT# 900234-20-XXX)

Connect to BACnet IP Network

or the Internet

CAT5-E Cable

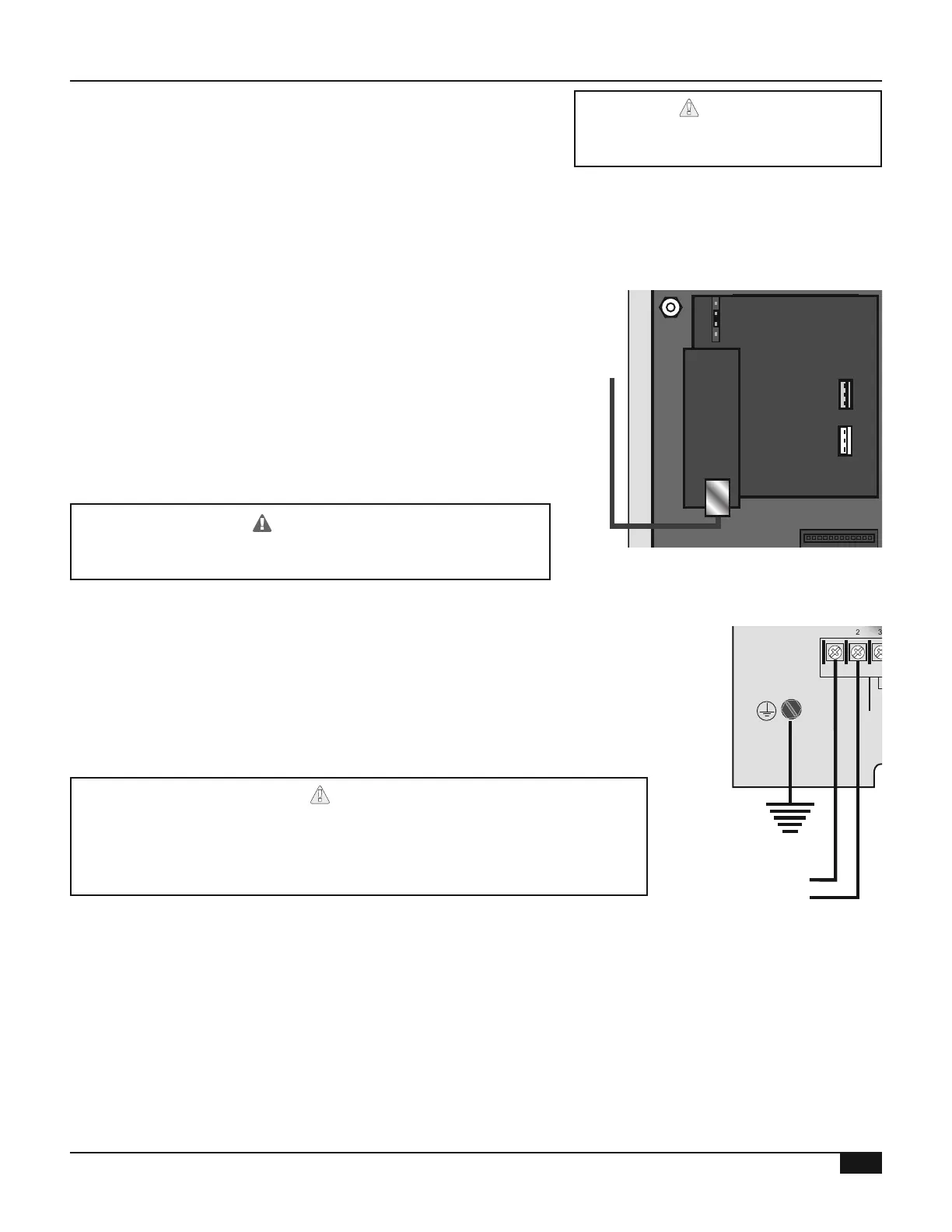

• Bring the 120VAC power wires through the enclosure's bottom knockouts

• Connect the hot line to the Line terminal (1) and connect the neutral line to

the Neutral terminal (2) Connect the green screw to Earth Ground

• Heat-Timer recommends the installation of a surge suppressor and a

power switch before the power line connection

• Use a separate circuit breaker for the control Do not share the control power

with other major equipment, pumps and motors

• Output relays do not source any power A separate power source must be

used Use the output relay to enable or disable the equipment

• Output relays do not source any power If the equipment connected to an

output relay requires power, an external power source must be used

• To use an output, you must install a relay Relays must be ordered

separately (HT# 500054-00)

• Each output relay on the Multi-MOD is rated for 1 Amp (1/8 HP) at 120

VAC 60 Hz If higher relay rating is required, connect the equipment to an

external relay Use the Multi-MOD output relay to control the external relay

MADE IN U.S.A.

SAFETY

GROUND

MUST BE

CONNECTED

OUT

TEMP

PROVE

/DHW

STAGE

A

STAGE

B

MENU FUNCTIONS

SELECT enters menus or accepts changes

ADJUST selects menu items or changes settings

BACK returns to previous menu

PREV./NEXT steps through stage status

DEL deletes schedule settings

STAGE

(DAY)

HELP NEXT

PRESS TO

SELECT

BACK

ADJUST

A1

A2

A3

A4

A5

A6

A7

A8

A9

A10

A11

A12

STAGE

C

DO NOT APPLY ANY VOLTAGE

TO SENSOR TERMINALS

B1

B2

B3

B4

B5

B6

NETWORK

PRESS

4-20 mA

SHUTDOWN

SYSTEM

TEMP

INPUTS

ROUTE SENSOR AND AUXILIARY WIRES

THROUGH THIS KNOCKOUT ONLY

<A> B C D

100% 50% --- ---

T

T

OUTPUT RATINGS:

120VAC, 6A RESISTIVE

1A PILOT DUTY

15A TOTAL

FOR ALL CIRCUITS

INPUT RATINGS:

115VAC 60Hz

30VA MAX

USE COPPER WIRE,

CLASS 1 WIRE ONLY

ENCLOSED

ENERGY

MANAGEMENT

EQUIPMENT

LISTED

99RA

STAGE selects stage menus or next stage

DAY selects next day

SYSTEM B C DA

LINE

NEUTRAL

1 2

3 4

5 6 7 8 9 10 11 12

FULL MODULATION

SEQUENCING CONTROL

LOCKOUT

INPUTS

STAGE

D

B7

B8

OPERATING LIMIT

OUTPUTS

SIGNAL

SHIELD

+

EMS

MODULATION OUTPUTS

A B C

D

C1 C2 C3 C4 C5 C6 C7 C8 C9 C10 C11 C12

S

+

L

N

Earth

Ground

120VAC

Loading...

Loading...