HT# 059299-00 A

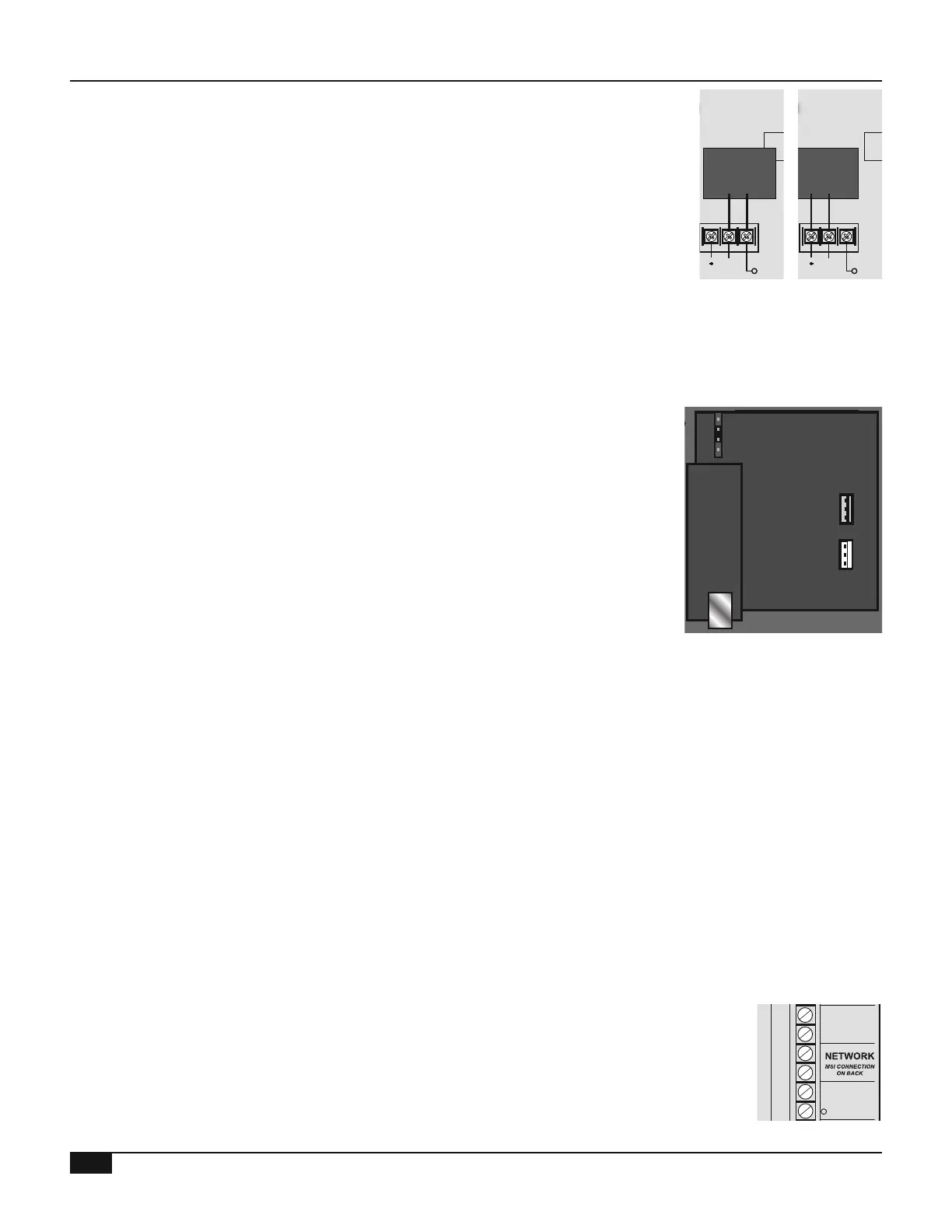

• The Multi-MOD Platinum can be congured to accept a remote 4-20mA set

point from an Energy Management System (EMS)

• Set the Multi-MOD Platinum EMS Input Mode to EMS-Control See "EMS

Input Mode" on page 27

• There are two ways to wire the 4-20mA signal The method used depends on

signal power source

• If the EMS sources the voltage for the 4-20mA signal, connect the EMS signal

(+) to the Multi-MOD EMS SIGNAL terminal Then connect the EMS signal (-)

to the Multi-MOD EMS SHIELD terminal This is the most common method

• If the Multi-MOD Platinum sources the current for the 4-20mA signal, connect

the EMS signal (+) to the Multi-MOD EMS + terminal Then connect the EMS

signal (-) to the Multi-MOD EMS SIGNAL terminal

MULTI-MOD

Platinum

MADE IN U.S.A.

PREV.

(DEL)

SAFETY

GROUND

MUST BE

CONNECTED

OUT

TEMP

PROVE

/DHW

STAGE

A

STAGE

B

MENU FUNCTIONS

SELECT enters menus or accepts changes

ADJUST selects menu items or changes settings

BACK returns to previous menu

PREV./NEXT steps through stage status

DEL deletes schedule settings

STAGE

(DAY)

HELP NEXT

PRESS TO

SELECT

BACK

ADJUST

A1

A2

A3

A4

A5

A6

A7

A8

A9

A10

A11

A12

STAGE

C

DO NOT APPLY ANY VOLTAGE

TO SENSOR TERMINALS

B1

B2

B3

B4

B5

B6

NETWORK

PRESS

4-20 mA

SHUTDOWN

SYSTEM

TEMP

INPUTS

ROUTE SENSOR AND AUXILIARY WIRES

THROUGH THIS KNOCKOUT ONLY

<A> B C D

100% 50% --- ---

T

T

OUTPUT RATINGS:

120VAC, 6A RESISTIVE

1A PILOT DUTY

15A TOTAL

FOR ALL CIRCUITS

INPUT RATINGS:

115VAC 60Hz

30VA MAX

USE COPPER WIRE,

CLASS 1 WIRE ONLY

ENCLOSED

ENERGY

MANAGEMENT

EQUIPMENT

LISTED

99RA

STAGE selects stage menus or next stage

DAY selects next day

SYSTEM B C DA

LINE

NEUTRAL

SYS

B C DA

1 2 3 4

5 6 7 8 9 10 11 12

FULL MODULATION

SEQUENCING CONTROL

LOCKOUT

INPUTS

STAGE

D

B7

B8

OPERATING LIMIT

OUTPUTS

SIGNAL

SHIELD

+

EMS

MODULATION OUTPUTS

A B C

D

C1 C2 C3 C4 C5 C6 C7 C8 C9 C10 C11 C12

S

+

4-20mA

Set Point

EMS

Sources

Power

(+)

(-)

MULTI-MOD

Platinum

MADE IN U.S.A.

PREV.

(DEL)

SAFETY

GROUND

MUST BE

CONNECTED

OUT

TEMP

PROVE

/DHW

STAGE

A

STAGE

B

MENU FUNCTIONS

SELECT enters menus or accepts changes

ADJUST selects menu items or changes settings

BACK returns to previous menu

PREV./NEXT steps through stage status

DEL deletes schedule settings

STAGE

(DAY)

HELP NEXT

PRESS TO

SELECT

BACK

ADJUST

A1

A2

A3

A4

A5

A6

A7

A8

A9

A10

A11

A12

STAGE

C

DO NOT APPLY ANY VOLTAGE

TO SENSOR TERMINALS

B1

B2

B3

B4

B5

B6

NETWORK

PRESS

4-20 mA

SHUTDOWN

SYSTEM

TEMP

INPUTS

ROUTE SENSOR AND AUXILIARY WIRES

THROUGH THIS KNOCKOUT ONLY

<A> B C D

100% 50% --- ---

T

T

OUTPUT RATINGS:

120VAC, 6A RESISTIVE

1A PILOT DUTY

15A TOTAL

FOR ALL CIRCUITS

INPUT RATINGS:

115VAC 60Hz

30VA MAX

USE COPPER WIRE,

CLASS 1 WIRE ONLY

ENCLOSED

ENERGY

MANAGEMENT

EQUIPMENT

LISTED

99RA

STAGE selects stage menus or next stage

DAY selects next day

SYSTEM B C DA

LINE

NEUTRAL

SYS

B C DA

1 2 3 4

5 6 7 8 9 10 11 12

FULL MODULATION

SEQUENCING CONTROL

LOCKOUT

INPUTS

STAGE

D

B7

B8

OPERATING LIMIT

OUTPUTS

SIGNAL

SHIELD

+

EMS

MODULATION OUTPUTS

A B C

D

C1 C2 C3 C4 C5 C6 C7 C8 C9 C10 C11 C12

S

+

4-20mA

Set Point

MMOD

Sources

Power

(+)

(-)

• Internet capable Multi-MOD Platinum controls are equipped with an Internet

communication board installed on the back of the main board

• Connect the Ethernet cable coming from the Internet Modem or Internet

server to the RJ45 socket on the back of the communication board

• See Platinum Internet Setup Manual for additional information on conguring

Internet controls and their features

N

5V

8V

Ethernet

RS485

Main Board

Control Stages

A & B

Control Stages

C & D

A1

G1

B1

A2

G2

B2

RS485

Communication Board

(HT# 900234-20-XXX)

• BACnet capable Multi-MOD Platinum controls has a BACnet communication

board that can communicate over BACnet IP or BACnet MSTP networks

• When using BACnet IP, connect the BACnet CAT5 Ethernet cable coming

from the BACnet network to the BACnet RJ45 Communication socket

(Ethernet socket) on the Multi-MOD communication board

• When using BACnet MSTP, connect the RS485 BACnet cable coming from

the BACnet network to the Black RS485 Communication socket on the

Multi-MOD communication board

• Set the Multi-MOD BACnet Settings as described in the BACnet Manual

• MODBUS capable Multi-MOD Platinum controls has a MODBUS

communication board that can communicate over MODBUS RTU networks

• Connect the RS485 BACnet cable coming from the MODBUS network to the

Black RS485 Communication socket on the Multi-MOD communication board

• Set the Multi-MOD MODBUS Settings as described in the MODBUS Manual

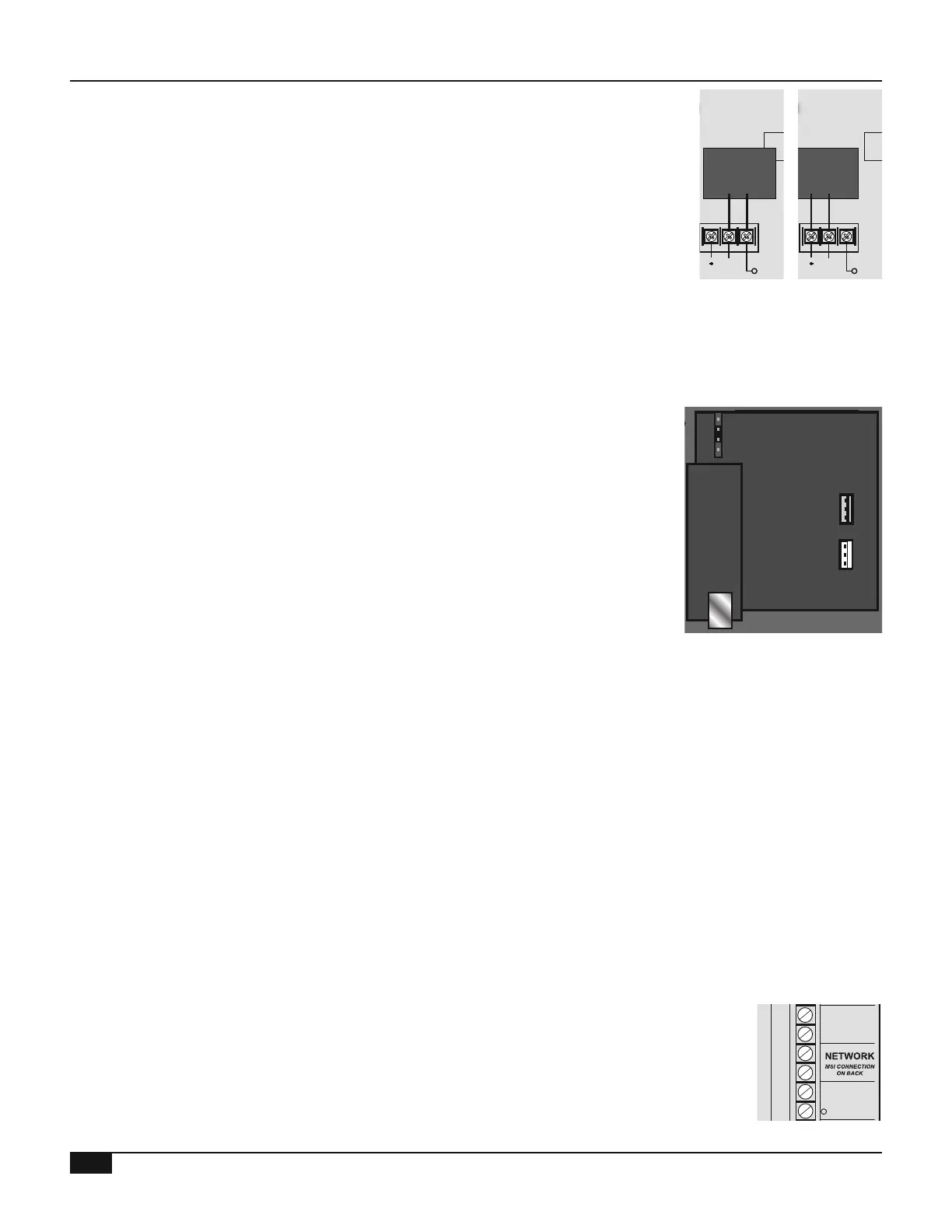

• The Multi-MOD Platinum with Internet communication is capable of connecting

to large number of Network sensor Heat-Timer has a variety of Network

Sensors that can measure temperature, pressure, vacuum, humidity, oil level,

and other mediums See Internet Communication Manual for information on

connecting and conguring network sensors

MULTI-MOD

Platinum

MADE IN U.S.A.

PREV.

(DEL)

SAFETY

GROUND

MUST BE

CONNECTED

OUT

TEMP

PROVE

/DHW

STAGE

A

STAGE

B

MENU FUNCTIONS

SELECT enters menus or accepts changes

ADJUST selects menu items or changes settings

BACK returns to previous menu

PREV./NEXT steps through stage status

DEL deletes schedule settings

STAGE

(DAY)

HELP NEXT

PRESS TO

SELECT

BACK

ADJUST

A1

A2

A3

A4

A5

A6

A7

A8

A9

A10

A11

A12

STAGE

C

DO NOT APPLY ANY VOLTAGE

TO SENSOR TERMINALS

B1

B2

B3

B4

B5

B6

NETWORK

PRESS

4-20 mA

SHUTDOWN

SYSTEM

TEMP

INPUTS

ROUTE SENSOR AND AUXILIARY WIRES

THROUGH THIS KNOCKOUT ONLY

<A> B C D

100% 50% --- ---

T

T

OUTPUT RATINGS:

120VAC, 6A RESISTIVE

1A PILOT DUTY

15A TOTAL

FOR ALL CIRCUITS

INPUT RATINGS:

115VAC 60Hz

30VA MAX

USE COPPER WIRE,

CLASS 1 WIRE ONLY

ENCLOSED

ENERGY

MANAGEMENT

EQUIPMENT

LISTED

99RA

STAGE selects stage menus or next stage

DAY selects next day

SYSTEM B C DA

LINE

NEUTRAL

SYS

B C DA

1 2 3 4

5 6 7 8 9 10 11 12

FULL MODULATION

SEQUENCING CONTROL

LOCKOUT

INPUTS

STAGE

D

B7

B8

OPERATING LIMIT

OUTPUTS

SIGNAL

SHIELD

+

EMS

MODULATION OUTPUTS

A B C

D

C1 C2 C3 C4 C5 C6 C7 C8 C9 C10 C11 C12

S

+

Loading...

Loading...