HT# 059299-00 A

• Attach the sensor wires to the Out Temp terminals (A11 and A12)

Temperature sensors have no polarity

• Connect the shield to terminal A12 with one of the other sensor

wires Do not connect the shield at the sensor end

• The sensor wires can be extended up to 500’ using shielded

2-conductor cable (#18/2)

MULTI-MOD

Platinum

MADE IN U.S.A.

PREV.

(DEL)

SAFETY

GROUND

MUST BE

CONNECTED

OUT

TEMP

PROVE

/DHW

STAGE

A

STAGE

B

MENU FUNCTIONS

SELECT enters menus or accepts changes

ADJUST selects menu items or changes settings

BACK returns to previous menu

PREV./NEXT steps through stage status

DEL deletes schedule settings

STAGE

(DAY)

HELP NEXT

PRESS TO

SELECT

BACK

ADJUST

A1

A2

A3

A4

A5

A6

A7

A8

A9

A10

A11

A12

STAGE

C

DO NOT APPLY ANY VOLTAGE

TO SENSOR TERMINALS

B1

B2

B3

B4

B5

B6

NETWORK

PRESS

4-20 mA

SHUTDOWN

SYSTEM

TEMP

INPUTS

ROUTE SENSOR AND AUXILIARY WIRES

THROUGH THIS KNOCKOUT ONLY

<A> B C D

100% 50% --- ---

T

T

OUTPUT RATINGS:

120VAC, 6A RESISTIVE

1A PILOT DUTY

15A TOTAL

FOR ALL CIRCUITS

INPUT RATINGS:

115VAC 60Hz

30VA MAX

USE COPPER WIRE,

CLASS 1 WIRE ONLY

ENCLOSED

ENERGY

MANAGEMENT

EQUIPMENT

LISTED

99RA

STAGE selects stage menus or next stage

DAY selects next day

SYSTEM B C DA

LINE

NEUTRAL

SYS

B C DA

1 2 3 4

5 6 7 8 9 10 11 12

FULL MODULATION

SEQUENCING CONTROL

LOCKOUT

INPUTS

STAGE

D

B7

B8

OPERATING LIMIT

OUTPUTS

SIGNAL

SHIELD

+

EMS

MODULATION OUTPUTS

A B C

D

C1 C2 C3 C4 C5 C6 C7 C8 C9 C10 C11 C12

S

+

Shield

System

Temperature

Sensor

TGT= 126

o

F

SYS= 125

o

F OD= 31

o

F

• The Multi-MOD Platinum can connect to a 4-20mA temperature

sensor (HT# 904160-00) See "Sensor Type" on page 26

• Locate the temperature sensor on the main supply header where

it will register the output of all the stages If the sensor cannot

read the output of all the stages, the Multi-MOD Platinum will not

be able to control the stages properly

• 4-20mA Temperature Sensor wires can be extended up to 500' by

splicing with 18 gauge twisted pair wire

• Connect the sensor's Blue wire to terminal PRESS - A5 (S)

• Connect the sensor's Brown wire to terminal PRESS - A6 (+)

• Cut the rest of the transducer wires and tubes

MULTI-MOD

Platinum

MADE IN U.S.A.

PREV.

(DEL)

SAFETY

GROUND

MUST BE

CONNECTED

OUT

TEMP

PROVE

/DHW

STAGE

A

STAGE

B

MENU FUNCTIONS

SELECT enters menus or accepts changes

ADJUST selects menu items or changes settings

BACK returns to previous menu

PREV./NEXT steps through stage status

DEL deletes schedule settings

STAGE

(DAY)

HELP NEXT

PRESS TO

SELECT

BACK

ADJUST

A1

A2

A3

A4

A5

A6

A7

A8

A9

A10

A11

A12

STAGE

C

DO NOT APPLY ANY VOLTAGE

TO SENSOR TERMINALS

B1

B2

B3

NETWORK

PRESS

4-20 mA

SHUTDOWN

SYSTEM

TEMP

INPUTS

ROUTE SENSOR AND AUXILIARY WIRES

THROUGH THIS KNOCKOUT ONLY

<A> B C D

100% 50% --- ---

T

T

OUTPUT RATINGS:

120VAC, 6A RESISTIVE

1A PILOT DUTY

15A TOTAL

FOR ALL CIRCUITS

INPUT RATINGS:

115VAC 60Hz

30VA MAX

USE COPPER WIRE,

CLASS 1 WIRE ONLY

ENCLOSED

ENERGY

MANAGEMENT

EQUIPMENT

LISTED

99RA

STAGE selects stage menus or next stage

DAY selects next day

SYSTEM B C DA

LINE

NEUTRAL

SYS

B C DA

1 2 3 4

5 6 7 8 9 10 11 12

FULL MODULATION

SEQUENCING CONTROL

LOCKOUT

INPUTS

STAGE

D

B7

B8

OPERATING LIMIT

OUTPUTS

SIGNAL

SHIELD

+

EMS

MODULATION OUTPUTS

A B C

D

C1 C2 C3 C4 C5 C6 C7 C8 C9 C10 C11 C12

S

+

TGT= 5 PSI

SYS= 4 PSI OD= 31

o

F

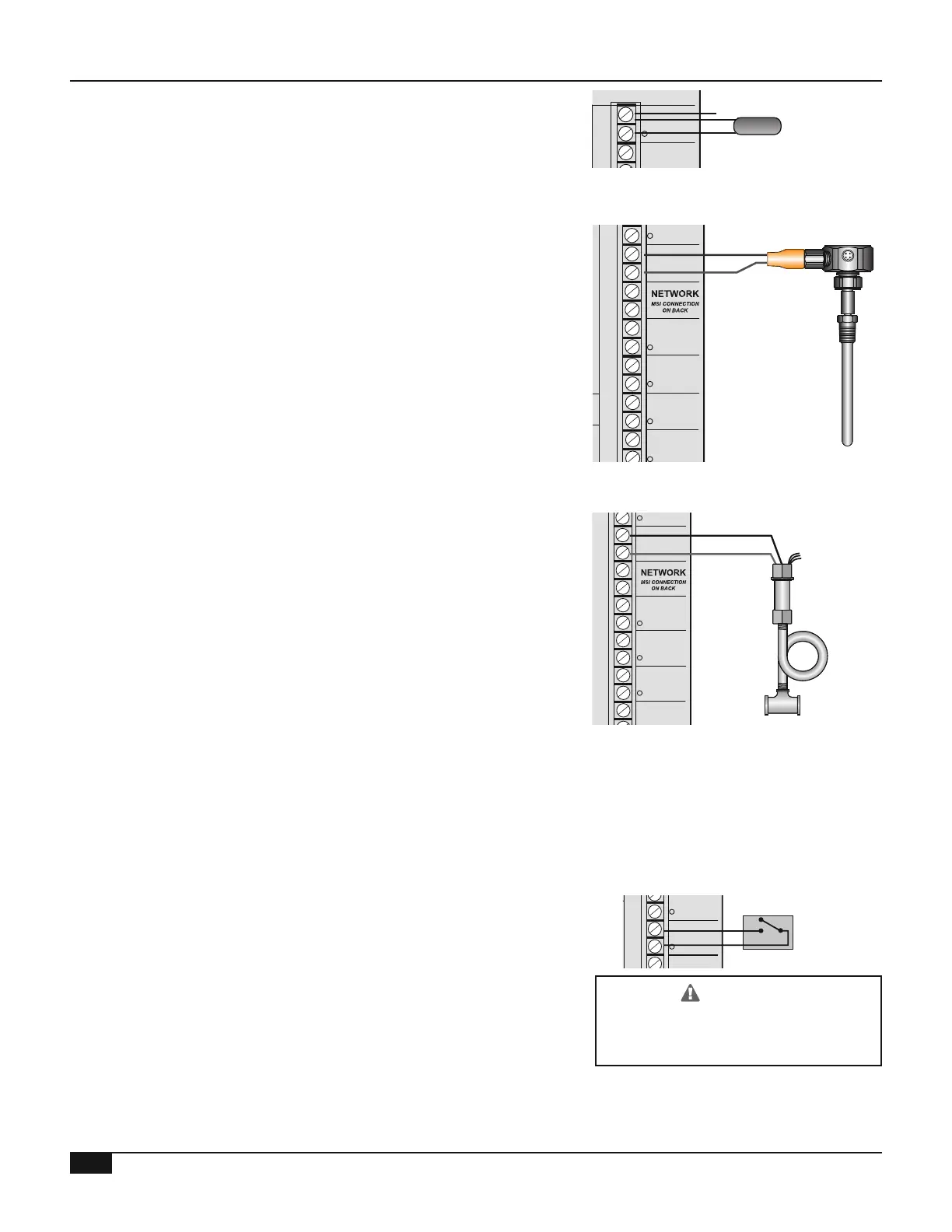

Brown (+)

Blue (-)

• The Multi-MOD Platinum is designed to connect to a pressure

transducer See "Sensor Type" on page 26

• Locate the transducer on the main supply header where it will

register the output of all the stages If the transducer cannot read

the output of all the stages, the Multi-MOD Platinum will not be

able to control the stages properly

• Attach the transducer to the steam header using a ¼" isolation

tube (pigtail) (HT# 135020-00)

• Pressure transducer wires can be extended up to 500' by splicing

with 18 gauge twisted pair wire

• Connect the Black wire from the pressure transducer to terminal

PRESS - A5 (S)

• Connect the Red wire from the pressure transducer to terminal

PRESS - A6 (+)

• Cut the rest of the transducer wires and tubes

MULTI-MOD

Platinum

MADE IN U.S.A.

PREV.

(DEL)

SAFETY

GROUND

MUST BE

CONNECTED

OUT

TEMP

PROVE

/DHW

STAGE

A

STAGE

B

MENU FUNCTIONS

SELECT enters menus or accepts changes

ADJUST selects menu items or changes settings

BACK returns to previous menu

PREV./NEXT steps through stage status

DEL deletes schedule settings

STAGE

(DAY)

HELP NEXT

PRESS TO

SELECT

BACK

ADJUST

A1

A2

A3

A4

A5

A6

A7

A8

A9

A10

A11

A12

STAGE

C

DO NOT APPLY ANY VOLTAGE

TO SENSOR TERMINALS

B1

B2

B3

NETWORK

PRESS

4-20 mA

SHUTDOWN

SYSTEM

TEMP

INPUTS

ROUTE SENSOR AND AUXILIARY WIRES

THROUGH THIS KNOCKOUT ONLY

<A> B C D

100% 50% --- ---

T

T

OUTPUT RATINGS:

120VAC, 6A RESISTIVE

1A PILOT DUTY

15A TOTAL

FOR ALL CIRCUITS

INPUT RATINGS:

115VAC 60Hz

30VA MAX

USE COPPER WIRE,

CLASS 1 WIRE ONLY

ENCLOSED

ENERGY

MANAGEMENT

EQUIPMENT

LISTED

99RA

STAGE selects stage menus or next stage

DAY selects next day

SYSTEM B C DA

LINE

NEUTRAL

SYS

B C DA

1 2 3 4

5 6 7 8 9 10 11 12

FULL MODULATION

SEQUENCING CONTROL

LOCKOUT

INPUTS

STAGE

D

B7

B8

OPERATING LIMIT

OUTPUTS

SIGNAL

SHIELD

+

EMS

MODULATION OUTPUTS

A B C

D

C1 C2 C3 C4 C5 C6 C7 C8 C9 C10 C11 C12

S

+

Cut the rest of

Connect to

1/4" pigtail

Black (-)

Red (+)

Transducer

4-20mA

TGT= 5 PSI

SYS= 4 PSI OD= 31

o

F

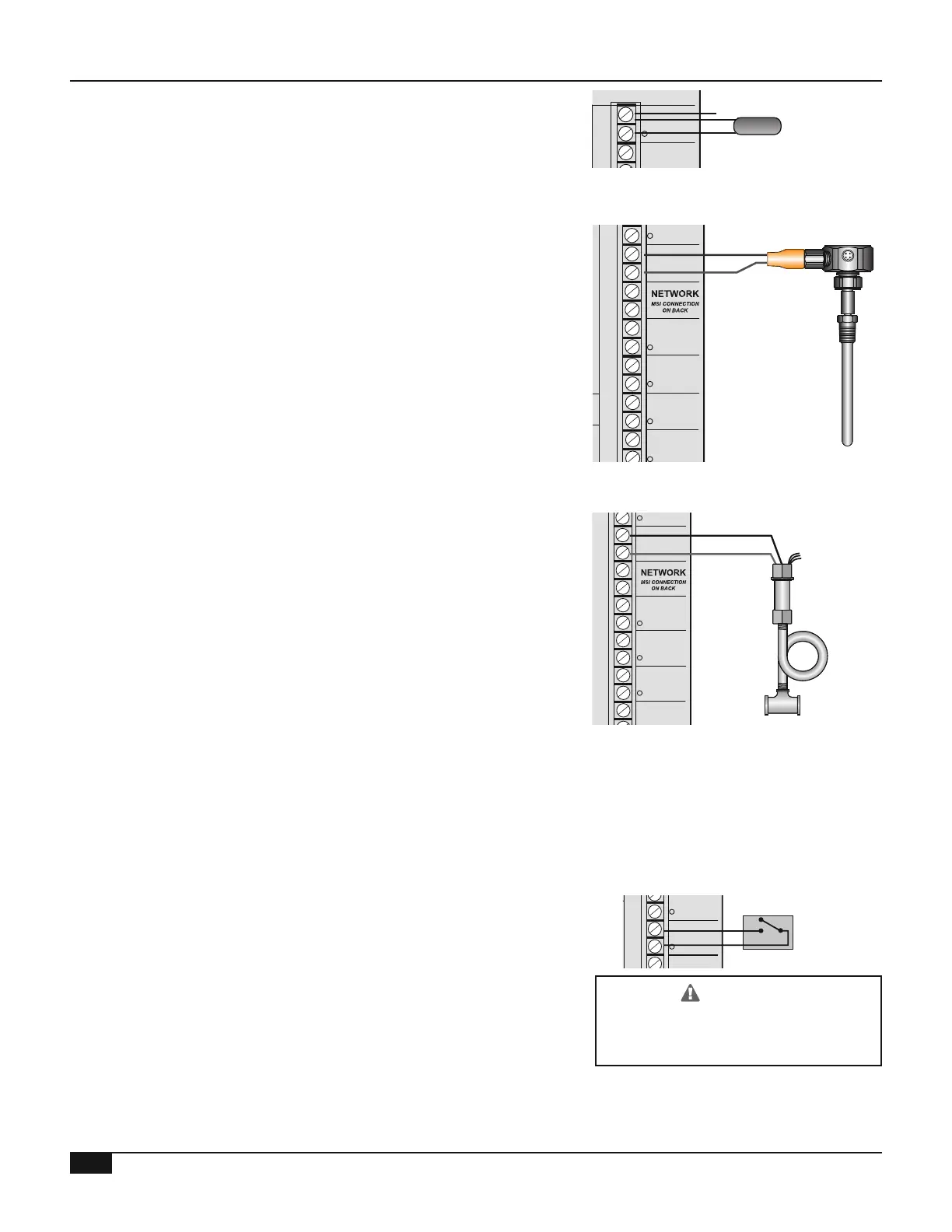

• The Shutdown is used to turn off the control remotely It can be

congured for Normally Open (Shutdown) or Normally Closed

(TSTAT)

• If boilers are running and he shutdown termnal is closed remotely

all active stages will modulate down to low re (Ignition %) They

will remain there until the adjustable Soft-Off period has nished

See page 37 for Soft-Off

• The System output will remain active until the Run-On Delay

ends, then it will also turn off See "System Run-On" on page 34

MULTI-MOD

Platinum

MADE IN U.S.A.

PREV.

(DEL)

SAFETY

GROUND

MUST BE

CONNECTED

OUT

TEMP

PROVE

/DHW

STAGE

A

STAGE

B

MENU FUNCTIONS

SELECT enters menus or accepts changes

ADJUST selects menu items or changes settings

BACK returns to previous menu

PREV./NEXT steps through stage status

DEL deletes schedule settings

STAGE

(DAY)

HELP NEXT

PRESS TO

SELECT

BACK

ADJUST

A1

A2

A3

A4

A5

A6

A7

A8

A9

A10

A11

A12

STAGE

C

DO NOT APPLY ANY VOLTAGE

TO SENSOR TERMINALS

B1

B2

B3

B4

B5

B6

NETWORK

PRESS

4-20 mA

SHUTDOWN

TEMP

INPUTS

ROUTE SENSOR AND AUXILIARY WIRES

THROUGH THIS KNOCKOUT ONLY

<A> B C D

100% 50% --- ---

T

T

OUTPUT RATINGS:

120VAC, 6A RESISTIVE

1A PILOT DUTY

15A TOTAL

FOR ALL CIRCUITS

INPUT RATINGS:

115VAC 60Hz

30VA MAX

USE COPPER WIRE,

CLASS 1 WIRE ONLY

ENCLOSED

ENERGY

MANAGEMENT

EQUIPMENT

LISTED

99RA

STAGE selects stage menus or next stage

DAY selects next day

SYSTEM B C DA

LINE

NEUTRAL

SYS

B C DA

1 2 3 4

5 6 7 8 9 10 11 12

FULL MODULATION

SEQUENCING CONTROL

LOCKOUT

INPUTS

STAGE

D

B7

B8

OPERATING LIMIT

OUTPUTS

SIGNAL

SHIELD

+

EMS

MODULATION OUTPUTS

A B C

D

C1 C2 C3 C4 C5 C6 C7 C8 C9 C10 C11 C12

S

Shutdown

Dry Contact

To avoid damage to the Multi-MOD,

NO VOLTAGE can be applied to the

Multi-MOD Platinum input terminals

Loading...

Loading...