HT# 059299-00 A

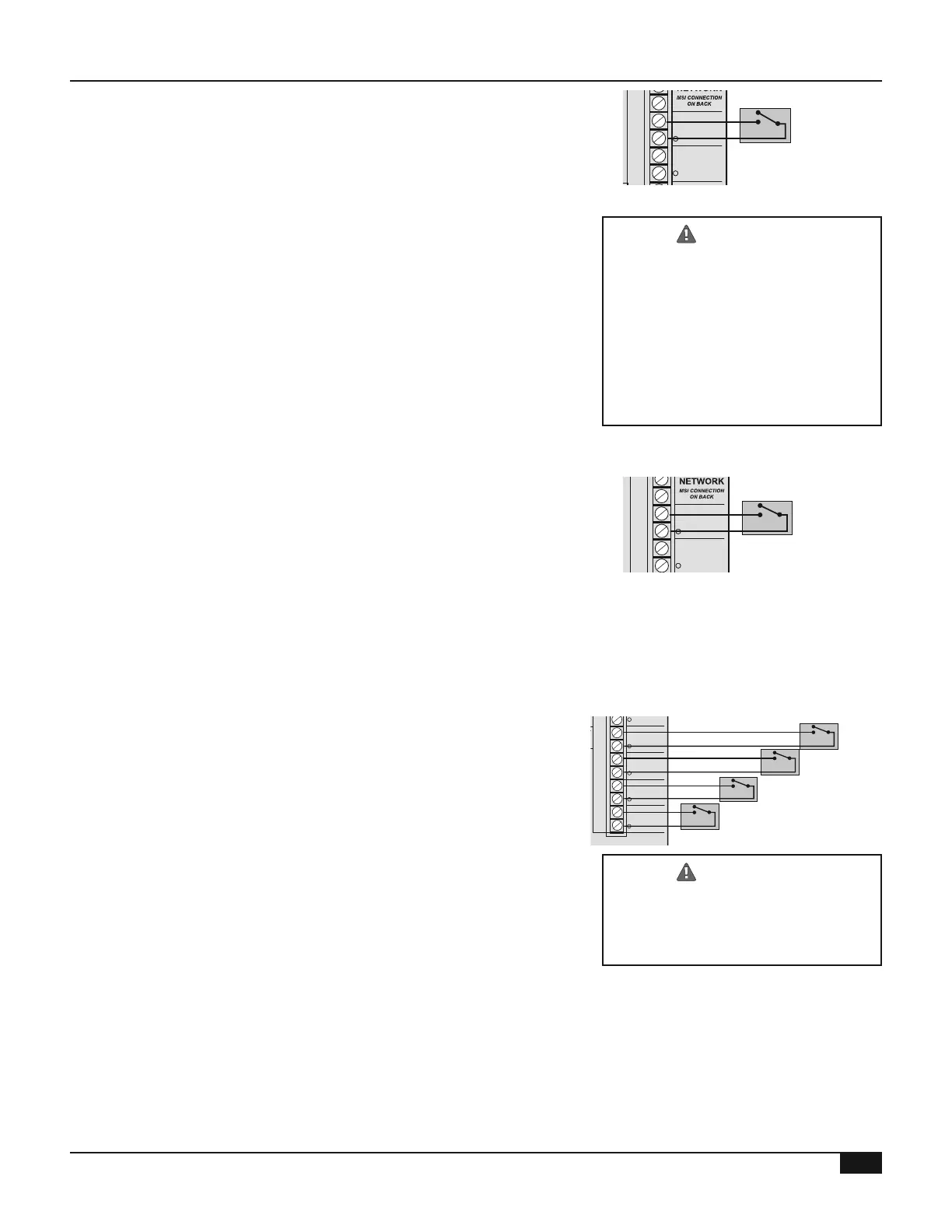

• The System Prove feature is provided to check the system

component operation status before activating any stages Prove

must be selected from the Prove/DHW Startup option See

"Prove/DHW Mode" on page 28

• A typical use of this feature is to check for water ow before ring

any boiler stages When there is a call for heat, the System

Output relay activates the system pump When the pump

establishes ow, a ow switch closes the Prove input terminals

Only then, can the Multi-MOD Platinum activate and modulate the

boilers as required to hold the set point

• If the Prove input is open on a call for a stage, the Multi-MOD

Platinum will enable only the System output All stage outputs

will be off when the Prove input is open

• A factory installed jumper provides the System Prove signal Do

not remove the jumper unless it is replaced by a Prove signal

MULTI-MOD

Platinum

MADE IN U.S.A.

PREV.

(DEL)

SAFETY

GROUND

MUST BE

CONNECTED

OUT

TEMP

PROVE

/DHW

STAGE

A

STAGE

B

MENU FUNCTIONS

SELECT enters menus or accepts changes

ADJUST selects menu items or changes settings

BACK returns to previous menu

PREV./NEXT steps through stage status

DEL deletes schedule settings

STAGE

(DAY)

HELP NEXT

PRESS TO

SELECT

BACK

ADJUST

A1

A2

A3

A4

A5

A6

A7

A8

A9

A10

A11

A12

STAGE

C

DO NOT APPLY ANY VOLTAGE

TO SENSOR TERMINALS

B1

B2

B3

B4

B5

B6

NETWORK

PRESS

4-20 mA

SHUTDOWN

SYSTEM

TEMP

INPUTS

ROUTE SENSOR AND AUXILIARY WIRES

THROUGH THIS KNOCKOUT ONLY

<A> B C D

100% 50% --- ---

T

T

OUTPUT RATINGS:

120VAC, 6A RESISTIVE

1A PILOT DUTY

15A TOTAL

FOR ALL CIRCUITS

INPUT RATINGS:

115VAC 60Hz

30VA MAX

USE COPPER WIRE,

CLASS 1 WIRE ONLY

ENCLOSED

ENERGY

MANAGEMENT

EQUIPMENT

LISTED

99RA

STAGE selects stage menus or next stage

DAY selects next day

SYSTEM B C DA

LINE

NEUTRAL

SYS

B C DA

1 2 3 4

5 6 7 8 9 10 11 12

FULL MODULATION

SEQUENCING CONTROL

LOCKOUT

INPUTS

STAGE

D

B7

B8

OPERATING LIMIT

OUTPUTS

SIGNAL

SHIELD

+

EMS

MODULATION OUTPUTS

A B C

D

C1 C2 C3 C4 C5 C6 C7 C8 C9 C10 C11 C12

S

+

Prove Input

Dry Contact

Do not remove the factory installed

Prove jumper unless it is replaced

by a prove signal If the Prove input

is not closed/shorted, the Multi-MOD

Platinum will NOT activate the stages

The Prove input cannot be used as

a safety limit All equipment must

have its own certified limit and safety

controls as required by code

• The DHW Call feature is used to raise the system Target to the

DHW Set Point In addition, it regulates the operation of the

System output The System output operation varies based on

the DHW Priority setting selected from the Startup menu See

"Prove/DHW Mode" on page 28

• Wire a DHW aquastat to the DHW Call terminals The call must

be dry-contact

• Remove the jumper on the DHW terminals for proper operation

MULTI-MOD

Platinum

MADE IN U.S.A.

PREV.

(DEL)

SAFETY

GROUND

MUST BE

CONNECTED

OUT

TEMP

PROVE

/DHW

STAGE

A

STAGE

B

MENU FUNCTIONS

SELECT enters menus or accepts changes

ADJUST selects menu items or changes settings

BACK returns to previous menu

PREV./NEXT steps through stage status

DEL deletes schedule settings

STAGE

(DAY)

HELP NEXT

PRESS TO

SELECT

BACK

ADJUST

A1

A2

A3

A4

A5

A6

A7

A8

A9

A10

A11

A12

STAGE

C

DO NOT APPLY ANY VOLTAGE

TO SENSOR TERMINALS

B1

B2

B3

B4

B5

B6

NETWORK

PRESS

4-20 mA

SHUTDOWN

SYSTEM

TEMP

INPUTS

ROUTE SENSOR AND AUXILIARY WIRES

THROUGH THIS KNOCKOUT ONLY

<A> B C D

100% 50% --- ---

T

T

OUTPUT RATINGS:

120VAC, 6A RESISTIVE

1A PILOT DUTY

15A TOTAL

FOR ALL CIRCUITS

INPUT RATINGS:

115VAC 60Hz

30VA MAX

USE COPPER WIRE,

CLASS 1 WIRE ONLY

ENCLOSED

ENERGY

MANAGEMENT

EQUIPMENT

LISTED

99RA

STAGE selects stage menus or next stage

DAY selects next day

SYSTEM B C DA

LINE

NEUTRAL

SYS

B C DA

1 2 3 4

5 6 7 8 9 10 11 12

FULL MODULATION

SEQUENCING CONTROL

LOCKOUT

INPUTS

STAGE

D

B7

B8

OPERATING LIMIT

OUTPUTS

SIGNAL

SHIELD

+

EMS

MODULATION OUTPUTS

A B C

D

C1 C2 C3 C4 C5 C6 C7 C8 C9 C10 C11 C12

S

+

DHW Call

Dry Contact

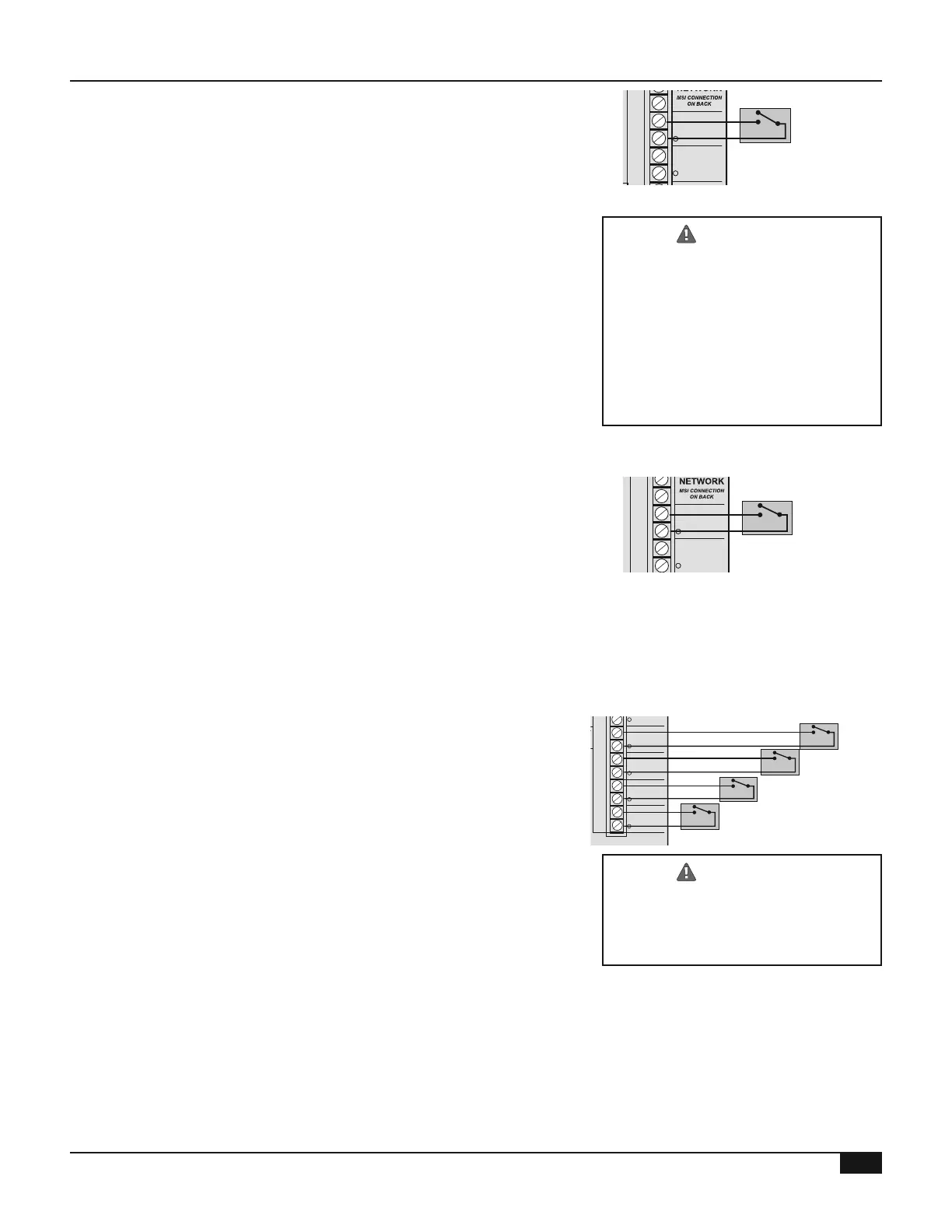

• The Multi-MOD Platinum will not activate or modulate any Stage

in Lockout A Lockout signal tells the Multi-MOD Platinum that

the related stage is encountering a problem and cannot be

started The Stage display status will show (L/O)

• However, using the Lockout will drastically improve the control's

set point management

• There is a Lockout input for each stage on the Multi-MOD

Platinum and Extension Module

• The Lockout signal must be a dry-contact closure from the boiler

No voltage can be placed across the terminals If the source of

the signal has voltage, use a relay

MULTI-MOD

Platinum

MADE IN U.S.A.

PREV.

(DEL)

SAFETY

GROUND

MUST BE

CONNECTED

OUT

TEMP

PROVE

/DHW

STAGE

A

STAGE

B

MENU FUNCTIONS

SELECT enters menus or accepts changes

ADJUST selects menu items or changes settings

BACK returns to previous menu

PREV./NEXT steps through stage status

DEL deletes schedule settings

STAGE

(DAY)

HELP NEXT

PRESS TO

SELECT

BACK

ADJUST

A1

A2

A3

A4

A5

A6

A7

A8

A9

A10

A11

A12

STAGE

C

DO NOT APPLY ANY VOLTAGE

TO SENSOR TERMINALS

B1

B2

B3

B4

B5

B6

NETWORK

PRESS

4-20 mA

SHUTDOWN

SYSTEM

TEMP

INPUTS

ROUTE SENSOR AND AUXILIARY WIRES

THROUGH THIS KNOCKOUT ONLY

<A> B C D

100% 50% --- ---

T

T

OUTPUT RATINGS:

120VAC, 6A RESISTIVE

1A PILOT DUTY

15A TOTAL

FOR ALL CIRCUITS

INPUT RATINGS:

115VAC 60Hz

30VA MAX

USE COPPER WIRE,

CLASS 1 WIRE ONLY

ENCLOSED

ENERGY

MANAGEMENT

EQUIPMENT

LISTED

99RA

STAGE selects stage menus or next stage

DAY selects next day

SYSTEM B C DA

LINE

NEUTRAL

SYS

B C DA

1 2 3 4

5 6 7 8 9 10 11 12

FULL MODULATION

SEQUENCING CONTROL

LOCKOUT

INPUTS

STAGE

D

B7

B8

OPERATING LIMIT

OUTPUTS

SIGNAL

SHIELD

+

EMS

MODULATION OUTPUTS

A B C

D

C1 C2 C3 C4 C5 C6 C7 C8 C9 C10 C11 C12

S

+

Boiler 1

Boiler 2

Lockout

Boiler 3

Lockout

Boiler 4

Lockout

Do not use the Lockout inputs as a

safety check All equipment must

have their certified limit and safety

controls installed as required by code

Loading...

Loading...