General

1-17

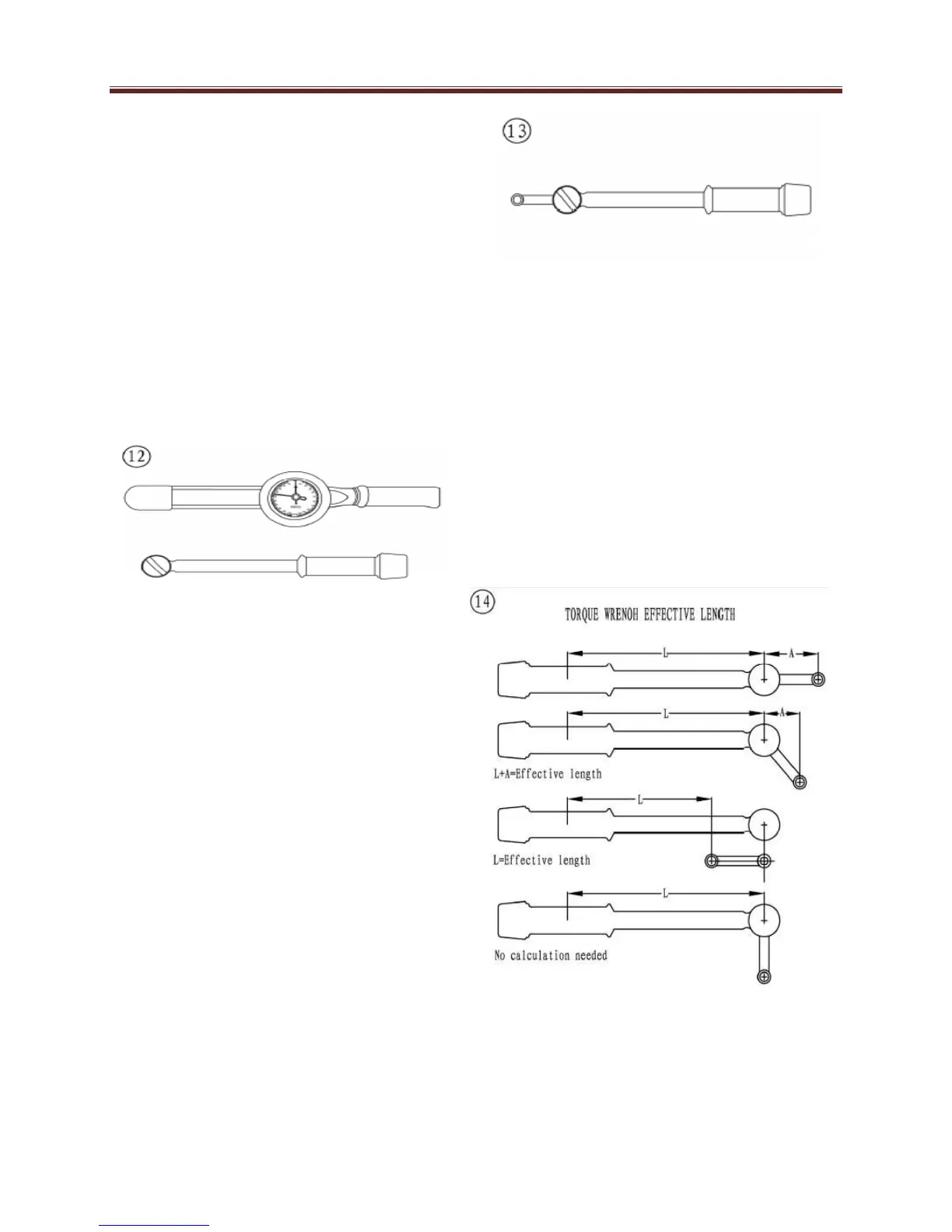

Torque Wrenches

Use a torque wrench with a socket,

torque adapter or similar extension to

tighten a fastener to a measured torque.

Torque wrenches come in several drive

sizes (1/4, 3/8, 1/2 and 3/4) and have

various methods of reading the torque

value. The drive size indicates the size

of the square drive that accepts the

socket, adapter or extension. Common

methods of reading the torque value are

the deflecting beam, the dial indicator

and the audible click (Figure 12).

When choosing a torque wrench,

consider the torque range, drive size and

accuracy. The torque specifications in

this manual provide an indication of the

range required. A torque wrench is a

precision tool that must be properly

cared for to remain accurate. Store

torque wrenches unloaded in cases or

separate padded drawers within a

toolbox. Follow the manufacturer’s

instructions for their care and calibration.

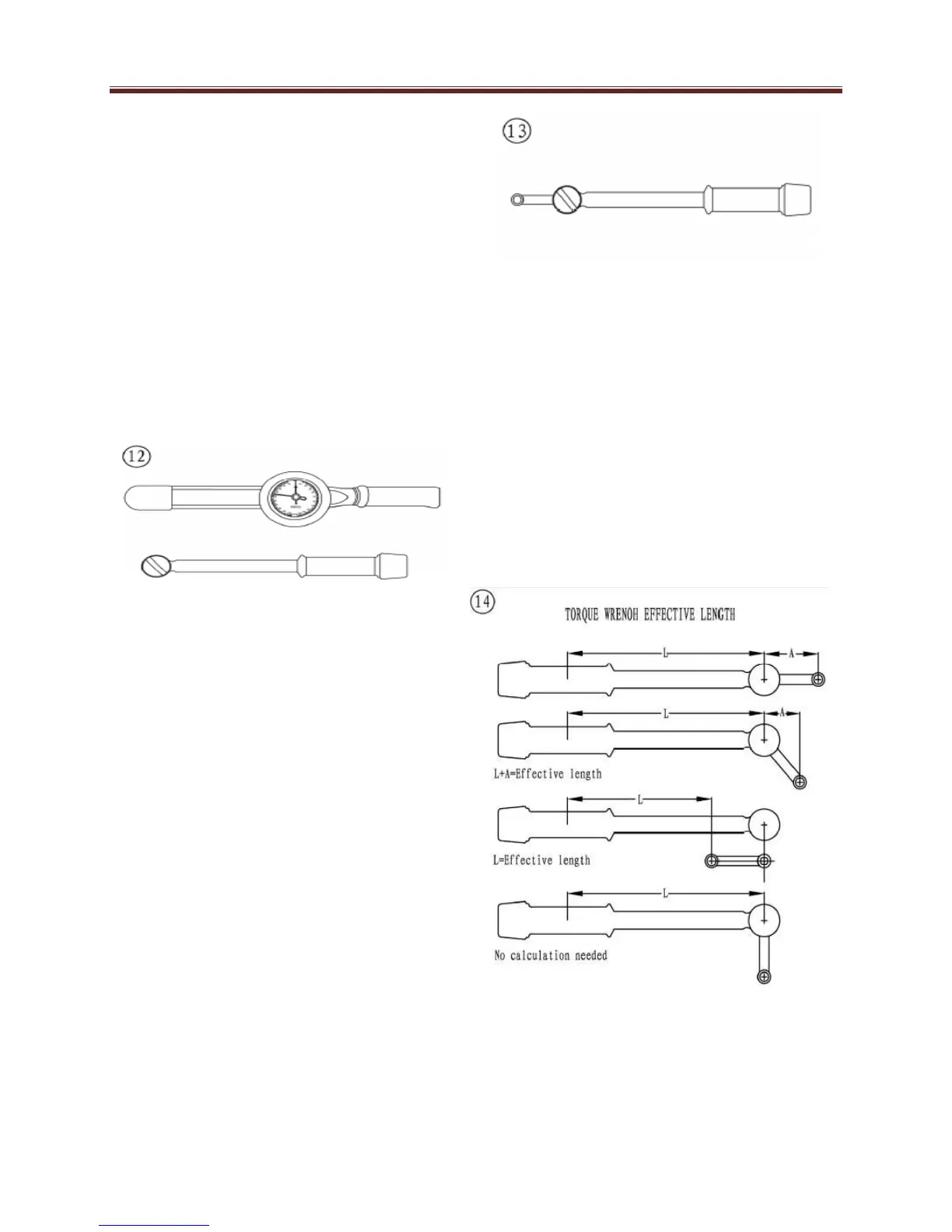

Torque Adapters

Torque adapters or extensions extend or

reduce the reach of a torque wrench.

The torque adapter shown in (Figure 13)

is used to tighten a fastener that cannot

be reached because of the size of the

torque wrench head, drive, and socket.

If a torque adapter changes the effective lever

length (Figure 14), the torque reading on the

wrench will not equal the actual torque

applied to the fastener. It is necessary to

recalibrate the torque setting on the wrench to

compensate for the change of lever length.

When using a torque adapter at a right angle

to the drive head, calibration is not required,

because the effective length has not

changed. To recalculate a torque reading

when using a torque adapter, use the

following formula and refer to Figure 14:

Loading...

Loading...