82 MAXPRO200 Instruction Manual 807700 Revision 1

Operation

Gouging

Specifications

Gouging safety

When gouging, it is absolutely necessary to wear full protection:

• A welding helmet with at least a #12 glass

• Welding gloves and a welding jacket.

• A heat shield (127389) can be purchased for further protection.

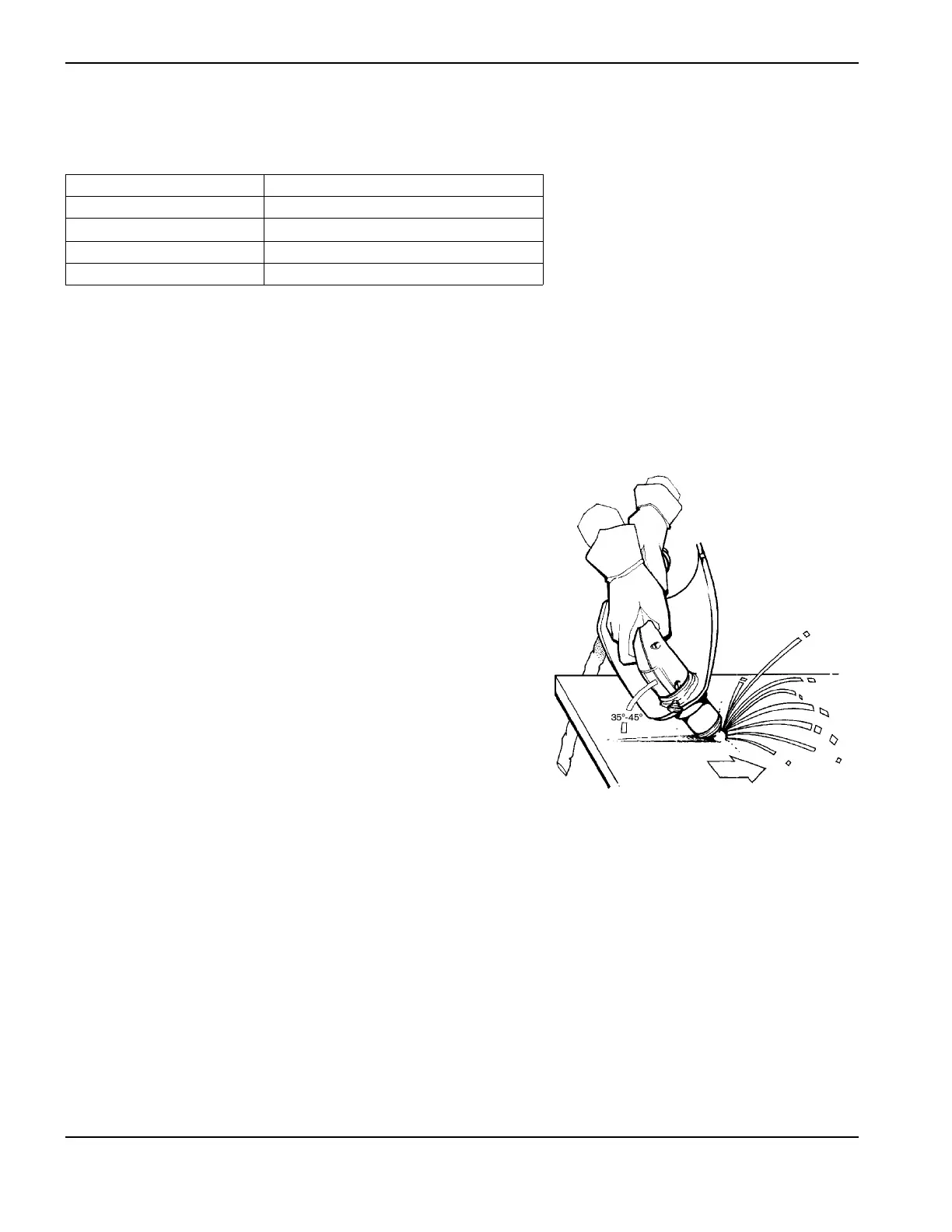

Gouge a workpiece

Note: To choose the correct consumables see Hand held

cutting and gouging consumable selection on page 87.

1. Hold the torch so that the torch tip is within 1.5 mm

(1/16 inch) from the workpiece before firing the torch.

2. Hold the torch at a 45° angle to the workpiece with a small

gap between the torch tip and the workpiece. Press the

trigger to obtain a pilot arc. Transfer the arc to the work piece.

3. Maintain an approximate 45° angle to the workpiece as you

feed into the gouge. Push the plasma arc in the direction of

the gouge you want to create. Keep a small distance between

the torch tip and the molten metal to avoid reducing

consumable life or damaging the torch.

Note: Changing the torch’s angle changes the dimensions of

the gouge.

Materials Mild steel, stainless steel, and aluminum

Current 200 Amps

Plasma gas types

Air, O

2

Shield gas types Air

Torch weight (without lead) See the Specification section

Loading...

Loading...