OPERATION

4-10

powermax

65/85

Operator Manual

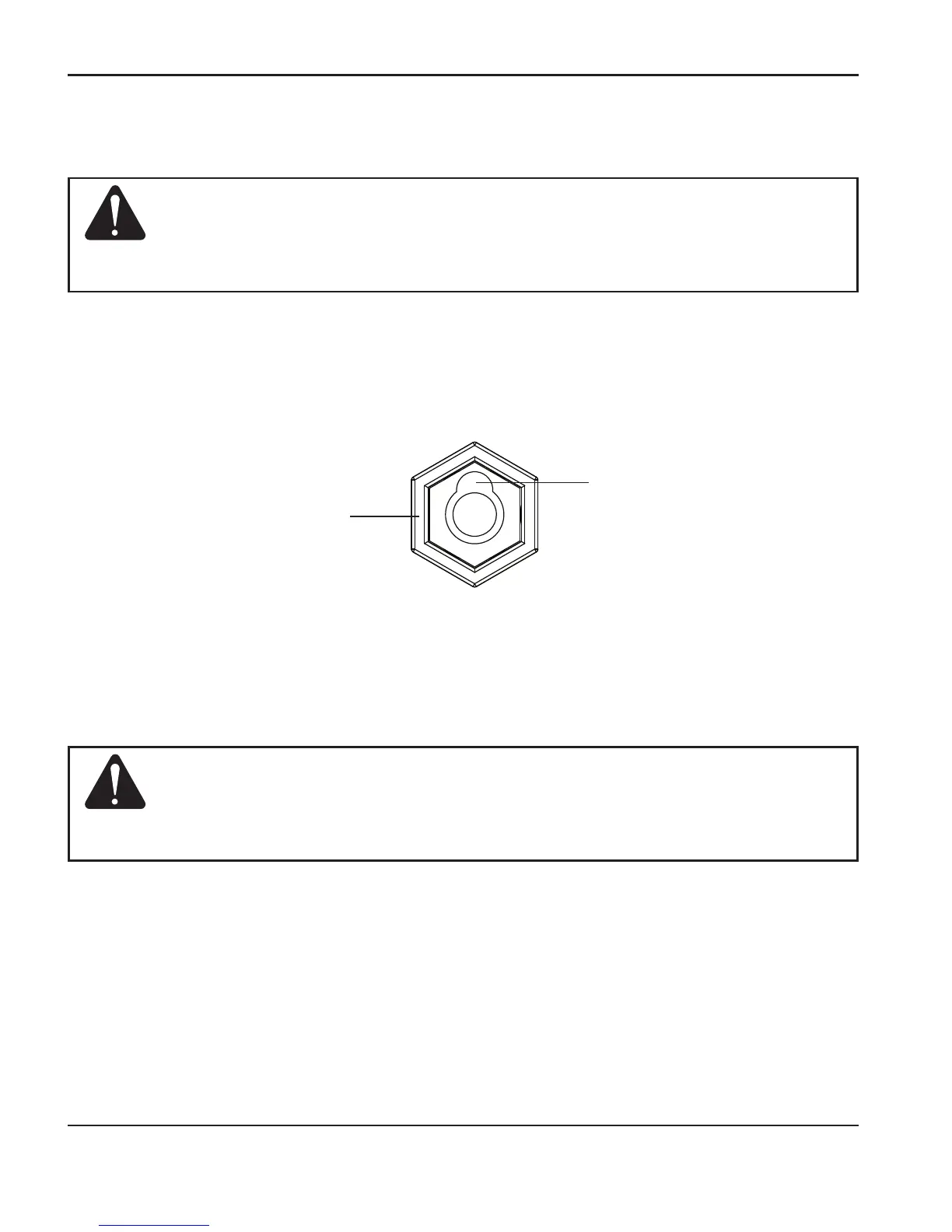

Work lead receptacle

on power supply

Keyed opening at

top of

receptacle

1. Insert the work lead connector into the receptacle on the front of the power supply.

ote:N The receptacle is keyed. Align the key on the work lead connector with the

opening at the top of the receptacle on the power supply.

aution:C Make sure you use a work lead that is appropriate for your

power supply. Use a 65A work lead with the Powermax65.

Use an 85A work lead with the Powermax85. The amperage is

marked near the rubber boot of the work lead connector.

2. Push the work lead connector all the way into the receptacle on the power supply and turn

clockwise, approximately 1/4 turn, until the connector is fully seated against the stop in order

to achieve an optimal electrical connection.

Attach the work lead to the power supply

aution:C Ensure the work lead is fully seated in the receptacle to

prevent overheating.

Loading...

Loading...