MAINTENANCE AND REPAIR

5-2

powermax

65/85

Operator Manual

Perform routine maintenance

Every use:

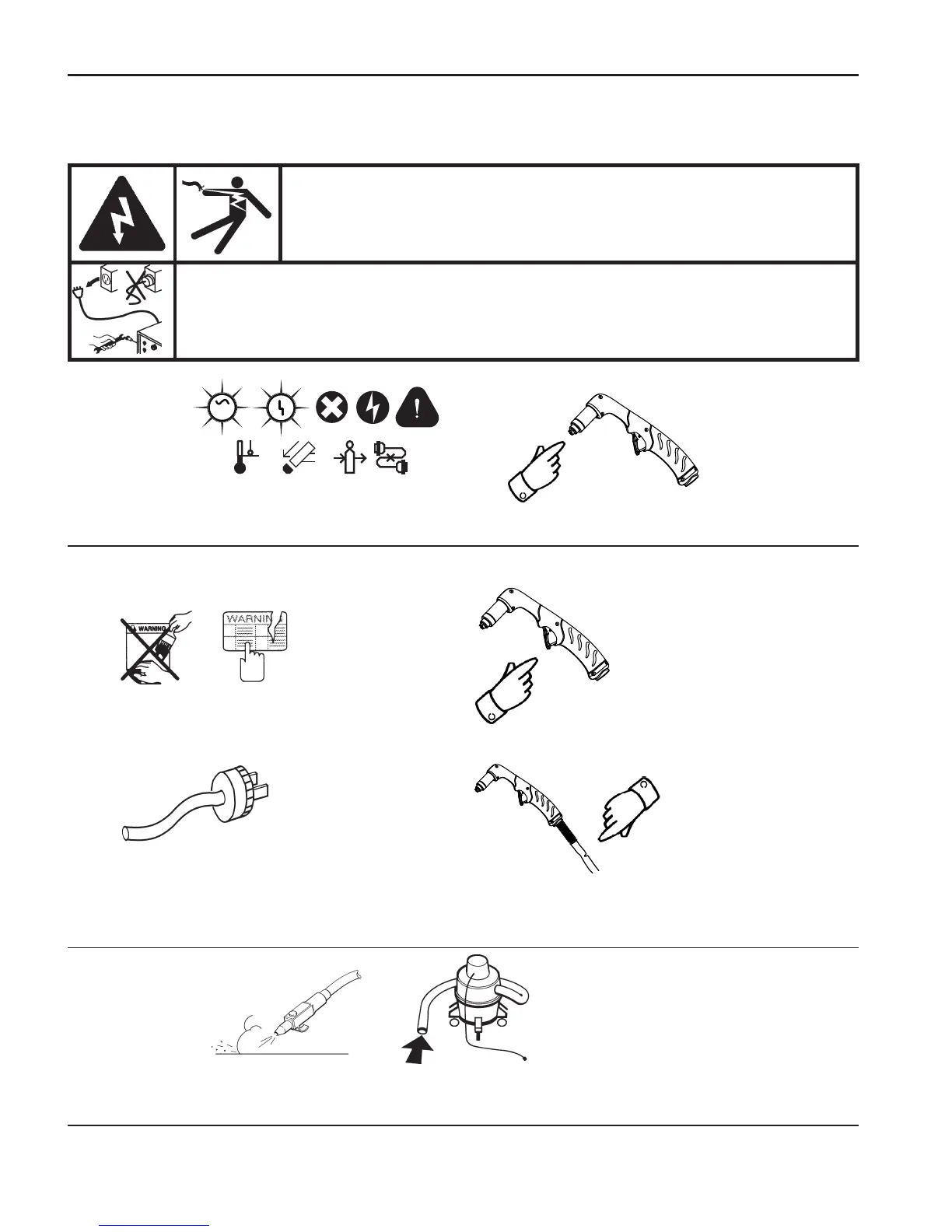

Check indicator lights and fault icons.

Correct any fault conditions.

Inspect the power cord and

plug. Replace if damaged.

Inspect the torch lead.

Replace if damaged.

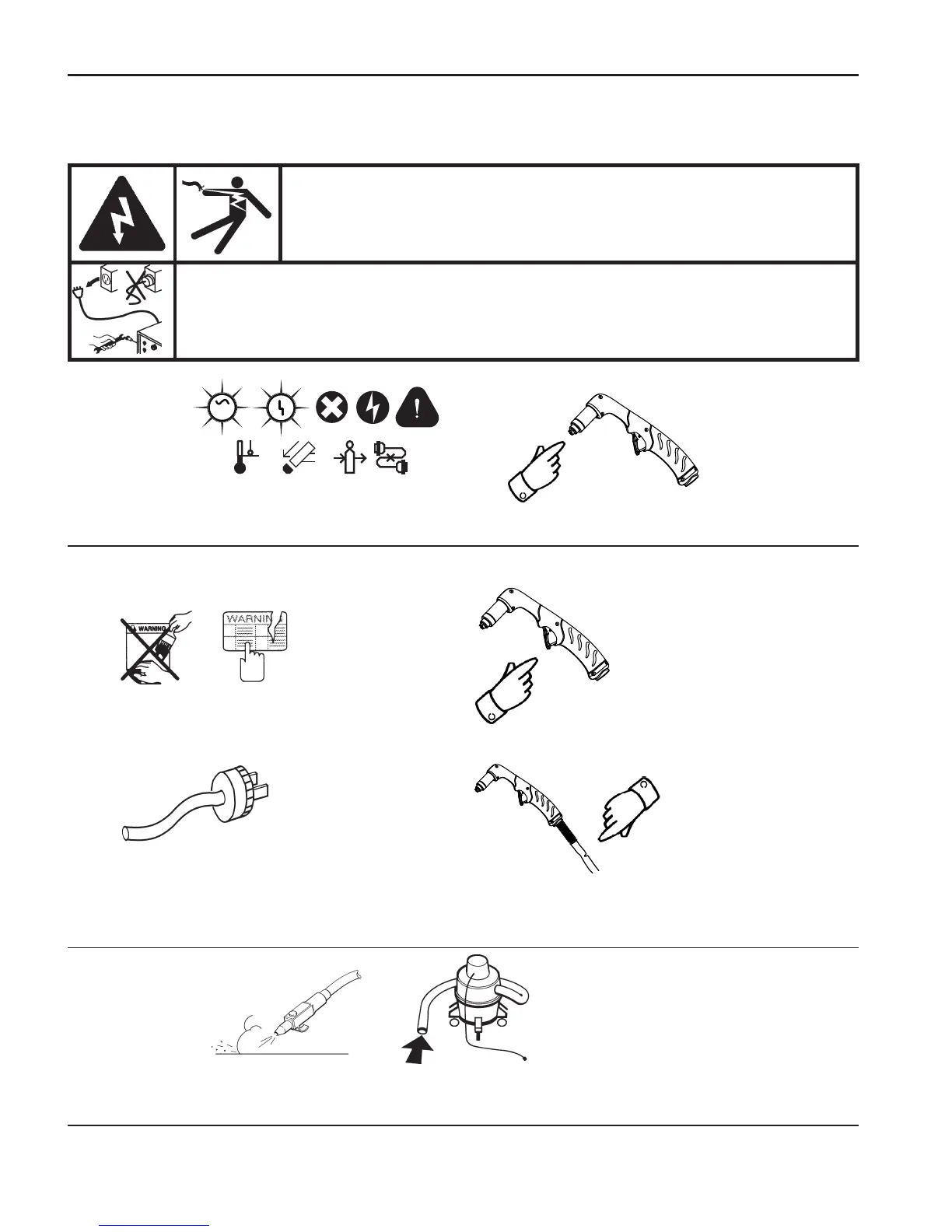

Clean the inside of the power supply

with compressed air or a vacuum.

Replace any damaged labels.

Inspect the

consumables for

proper installation

and wear.

Inspect the trigger for

damage. Inspect the

torch body for cracks and

exposed wires. Replace

any damaged parts.

Every 6 months:

Every 3 months:

Or

DANGER

ELECTRIC SHOCK CAN KILL

Disconnect the electrical power before you perform any maintenance.

Allwork that requires removal of the power supply cover must be

performed by a qualified technician.

AC

Loading...

Loading...