MAINTENANCE AND REPAIR

powermax

65/85

Operator Manual 5-5

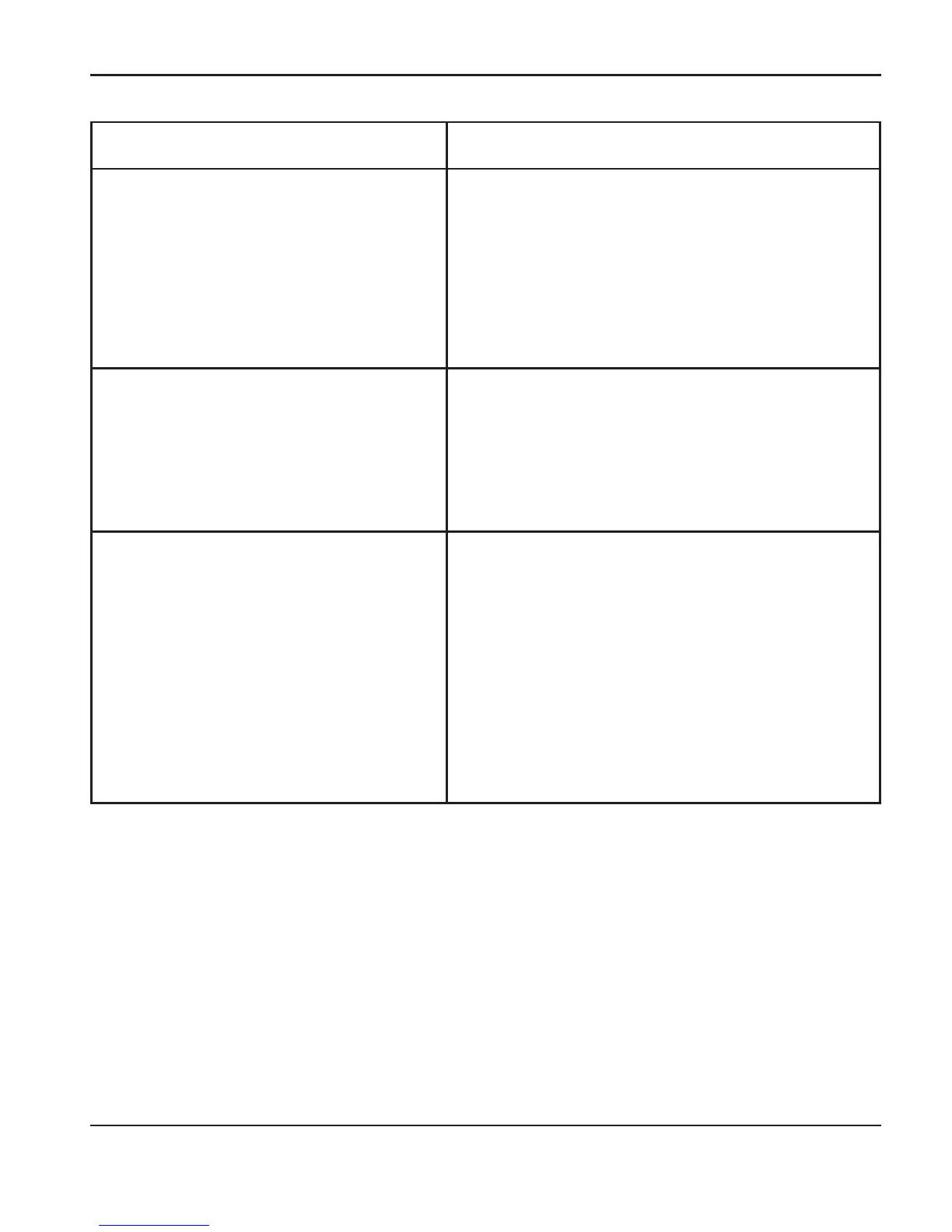

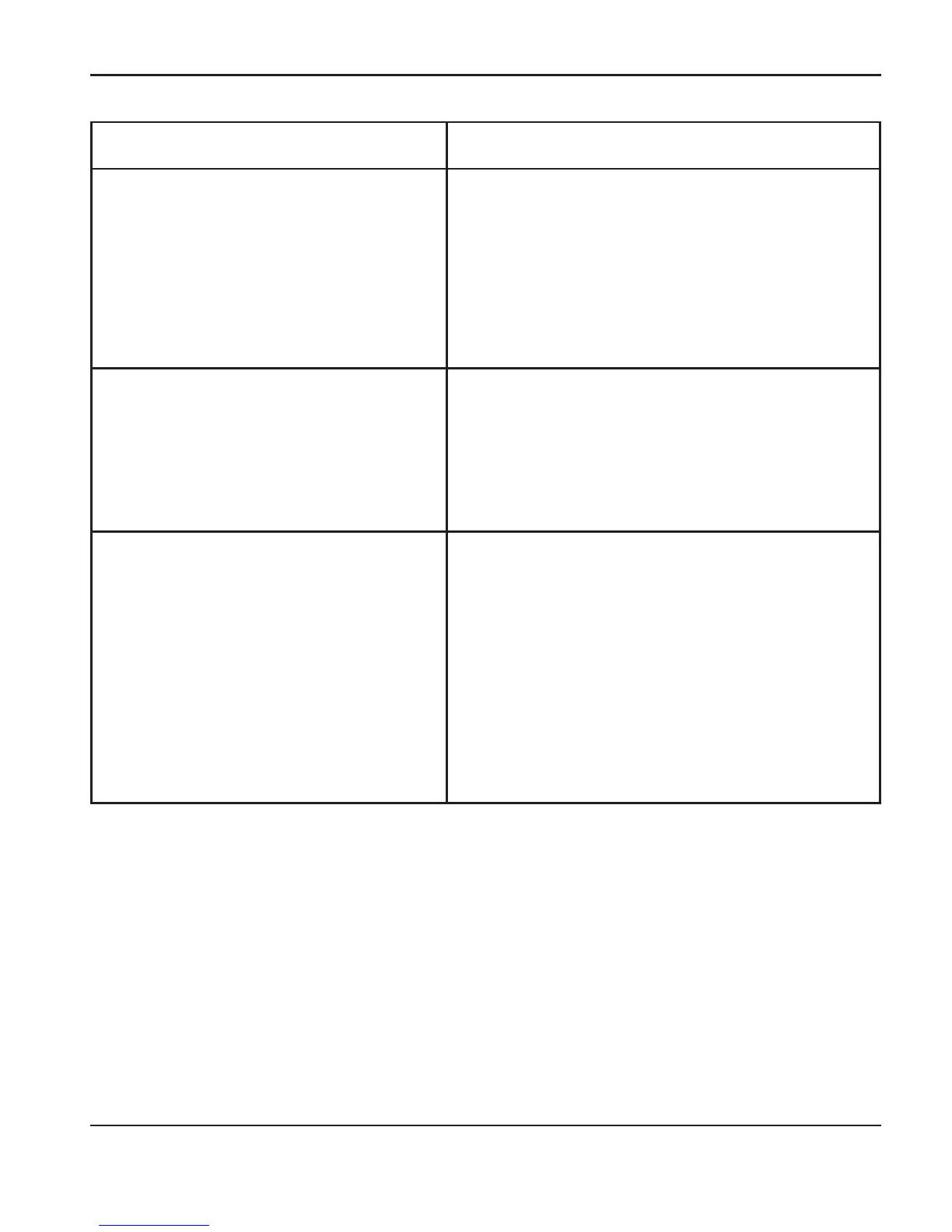

Problem Solutions

The arc blows out, but re-ignites when

the torch trigger is pressed again.

• Inspect the consumable parts and replace them

if they are worn or damaged. See “Inspect the

consumables” on page 5-3.

• Replace the gas filter’s element if it is

contaminated. See “Replace the gas filter

element” on page 5-10.

• Make sure the gas pressure is at the proper level.

The arc sputters and hisses. • The gas filter’s element is contaminated. Replace

the element. See “Replace the gas filter element”

on page 5-10.

• Inspect the gas line for moisture. If necessary,

install or repair the gas filtration to the power

supply. See “Prepare the gas supply” on page 2-14.

The cut quality is poor. • Verify that the torch is being used correctly. See

Section 4, Operation.

• Inspect the consumables for wear and replace

as necessary. See “Inspect the consumables” on

page 5-3.

• Check the air pressure and air quality.

• Verify that the cutting mode switch is in the

proper position for the cutting operation.

• Verify that the correct consumables are installed.

Loading...

Loading...