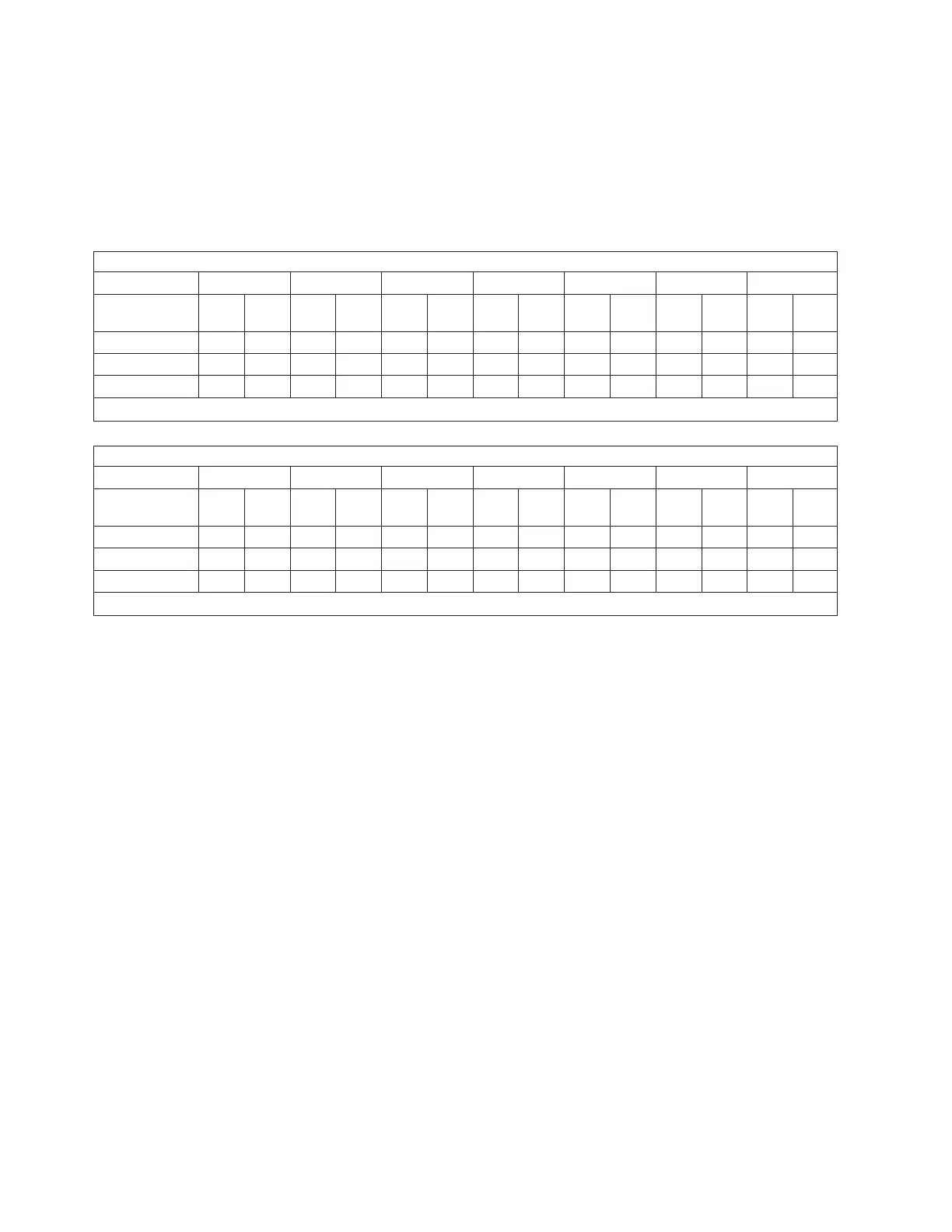

v Machine load is listed in total ac input power (power for both line cords combined)

v A fresh battery is defined as 2.5 years old or less.

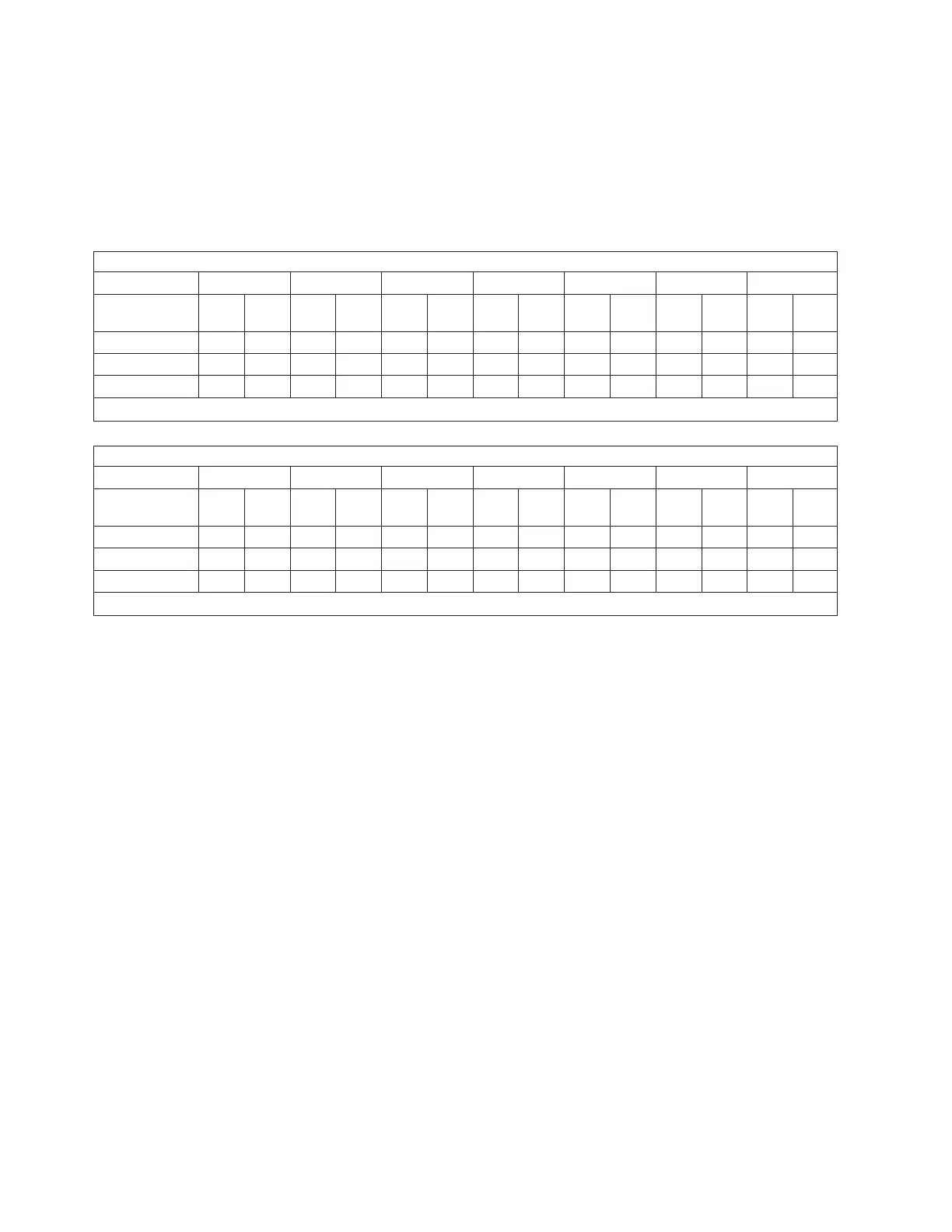

v An aged battery is defined as 6.5 years.

Note: Battery capacity decreases gradually as the battery ages (from fresh-battery value to aged-battery

value). The system diagnoses a failed-battery condition if the capacity decreases below the

aged-battery value.

Typical Machine-Holdup Time vs. Load for Fresh Battery

Machine Load 3 kW 6 kW 9 kW 12 kW 15 kW 18 kW 19.5 kW

IBF

Configuration

N R N R N R N R N R N R N R

1 BPR 7.0 21.0 2.1 7.0

2 BPR 21.0 50.0 7.0 21.0 4.0 11.0 2.1 7.0

3 BPR 32.0 68.0 12.0 32.0 7.0 21.0 4.9 12.0 3.2 9.5 2.1 7.0 1.7 6.5

N=Non-redundant, R=Redundant

Typical Machine-Holdup Time vs. Load for Aged Battery

Machine Load 3 kW 6 kW 9 kW 12 kW 15 kW 18 kW 19.5 kW

IBF

Configuration

N R N R N R N R N R N R N R

1 BPR 4.2 12.6 1.3 4.2

2 BPR 12.6 30.0 4.2 12.6 2.4 6.6 1.3 4.2

3 BPR 19.2 41.0 7.2 19.2 4.2 12.6 2.9 7.2 1.9 5.7 1.3 4.2 1.0 3.9

N=Non-redundant, R=Redundant

Guide for Raised-Floor Preparation

Although a raised floor is not required for the Eserver pSeries 655, it is recommended for optimum

system cooling and cable management. Raised floor cutouts should be protected by electrically

nonconductive molding, appropriately sized, with edges treated to prevent cable damage and to prevent

casters from rolling into the floor cutouts.

Front-service access is necessary on the Eserver pSeries 655 to accommodate a lift tool for the

servicing of large drawers (the processor nodes and I/O drawers). Front and rear service access is

104 Site and Hardware Planning Information

Loading...

Loading...