J

'-

!/

-'-

/

..........

"-

I \

I 1

\ J

\.

/

A

B

Play Removed

In

The

Negative

Direction

Play Removed

In

The Positive Direction

FIGURE

67.

Tilt Detent Entry

5.

Rotate Spring Tension - Adjust

the

rotate

spring

in

the

rocker so

that

it

wi

II

have

1-7/8

to

2 pounds tension

when

the

machine

is

half-cycled

using a lower case

neg-

ative

5

character.

The least amount of tension

is

pres-

ent

in

the

spring when it

is

in this positi

on.

The typehea

...

must be removed when making this

adjustment.

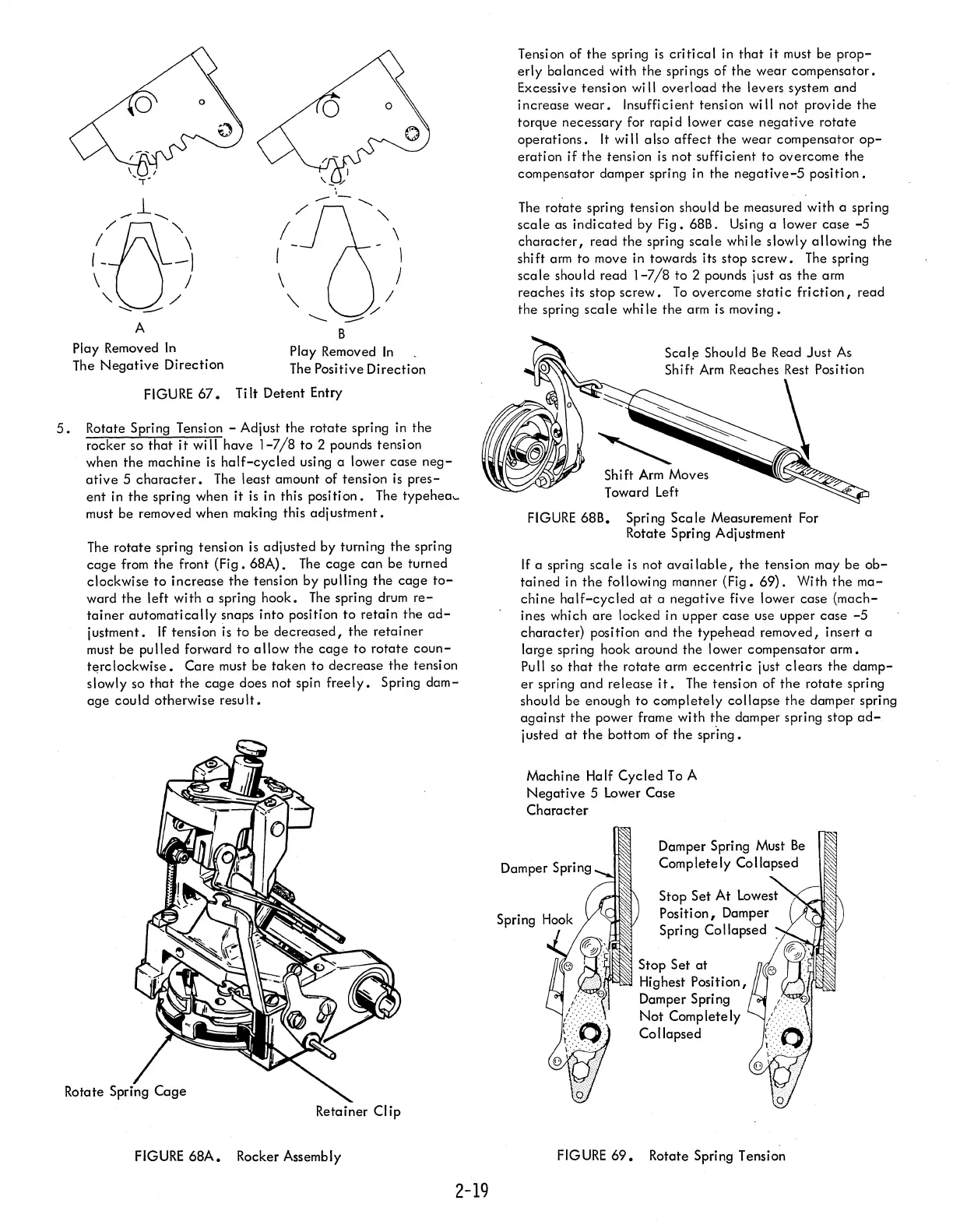

The

rotate

spring tension is adjusted by turning

the

spring

cage

from

the

front

(Fig.

68A).

The

cage

can be turned

clockwise to

increase

the

tension by pulling

the

cage

to-

ward

the

left with a spring hook.

The

spring drum

re-

tainer

automatically

snaps into position

to

retain

the

ad-

justment.

If

tension

is

to

be

decreased,

the

retainer

must be

pulled

forward

to

allow

the

cage

to

rotate

coun-

tE!rclockwise.

Care

must be taken to decrease

the

tension

slowly so

that

the

cage

does not spin

freely.

Spring

dam-

age

could otherwise

result.

Rotate Spr

Retainer Clip

FIGURE

68A.

Rocker Assembly

2-19

Tension of

the

spring

is

critical

in

that

it

must be

prop-

erly

balanced

with

the

springs

of

the

wear compensator.

Excessive tension

wi

II

overload

the

levers system and

increase

wear.

Insuffi ci ent tensi

on

wi

II

not provide

the

torque necessary for rapi d lower case

negative

rotate

operations.

It

will also

affect

the

wear

compensator

op-

eration

if

the

tension

is

not sufficient to overcome the

compensator damper spring in the

negative-5

position.

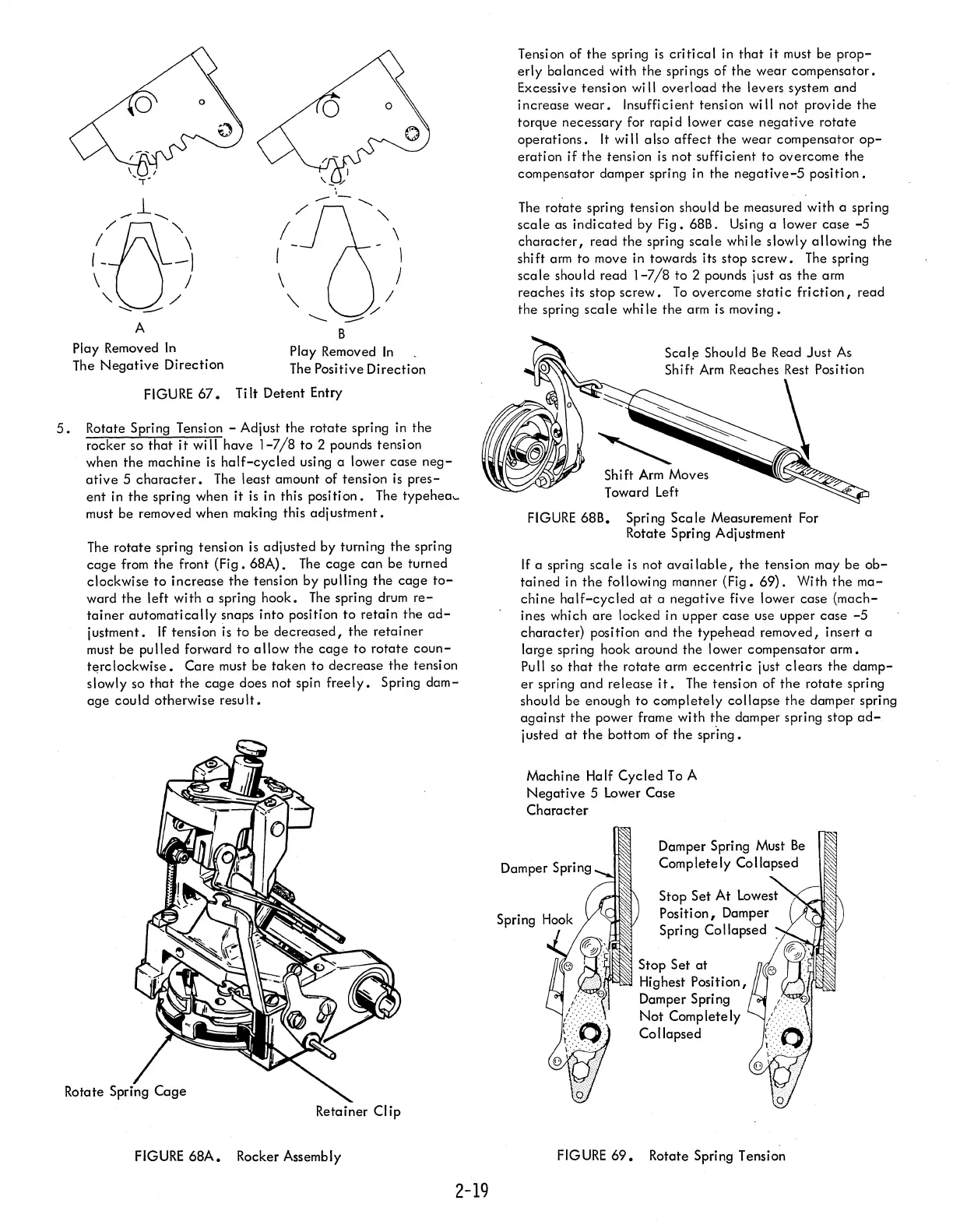

The

rotate spring tension should be measured with a spring

scale

as

indicated

by Fig. 68B. Using a lower case

-5

character,

read

the

spring

scale

while slowly allowing

the

shift arm to move in towards its stop

screw.

The

spring

scale

shou

Id

read

1-7/8

to 2 pounds just as

the

arm

reaches its stop

screw.

To

overcome

static

friction,

read

the

spring

scale

while

the

arm

is

moving.

Shift

Arm

Moves

Toward Left

FIGURE

68B. Spring

Scale

Measurement For

Rotate Spring Adjustment

If

a spring

scale

is

not

available,

the

tension may be

ob-

tained

in

the

following manner

(Fig.

69).

With

the

ma-

chine

half-cycled

at

a

negative

five lower case {mach-

ines which

are

locked in upper case use upper case

-5

character} position

and

the

typehead

removed, insert a

large spring hook around

the

lower compensator

arm.

Pull

so

that

the

rotate

arm

eccentric

just

clears

the

damp-

er

spring

and

release

it.

The tensi

on

of

the

rotate

spring

should be enough to completely

collapse

the

damper spring

against

the

power frame with

the

damper spring stop

ad-

justed

at

the

bottom

of

the

spr"ing.

Machine Half

Cycled

To

A

Negative

5

lower

Case

Character

Damper Spring Must

Be

Completely Collapsed

Stop

Set

at

Highest Position I

Damper Spring

Not

Completely

Collapsed

FIGURE

69.

Rotate Spring Tension

Loading...

Loading...