+5

+4

+3

+2

+1

0

-1

-2 -3

-,

-5

I\.

/,

/\

1,\

1\

,~\

/\

/\

J\

/\

1\

,"

I , "

,"

"

L'

/

L_,

,_~,

,<,'

I \ I \

I

~

I

I,

I

..

_~

I

""\

1 \ r

'r--

,

I'

I ,

,

"I

L.-\

I , , \ I \ I ,

I'

'\

I ,

L.

-~

V " "

"'v

.;

\

~

Affected

By

FIGURE

78.

Insufficient Rotate

Arm

Motion

Ratio Change

detent

well within the

acceptable

band width provided

that

all

of

the

previous adjustments have been made

cor-

rectly.

If

a slight difference

in

detenting must exist

be-

tween

the

-3

and

+5

characters it

is

permissible and some-

times desirable provided

that

the

-3

detents more

nega-

tive then

the

+5

character.

In

other words, it

is

better

to have too much rotate arm motion than too

little.

The

reason for this

is

to

place

a small amount of wear

poten-

tial

into

the

system for the areas of the differential

mech-

anism where

wear

cannot be compensated for (positive

latches and latch

bail).

Thus, as wear occurs in these

areas causing

the

rotate arm motion to

decrease,

the

de-

tenti

ng

variati

on

between

the

+5

and

-3

characters will

also

reduce.

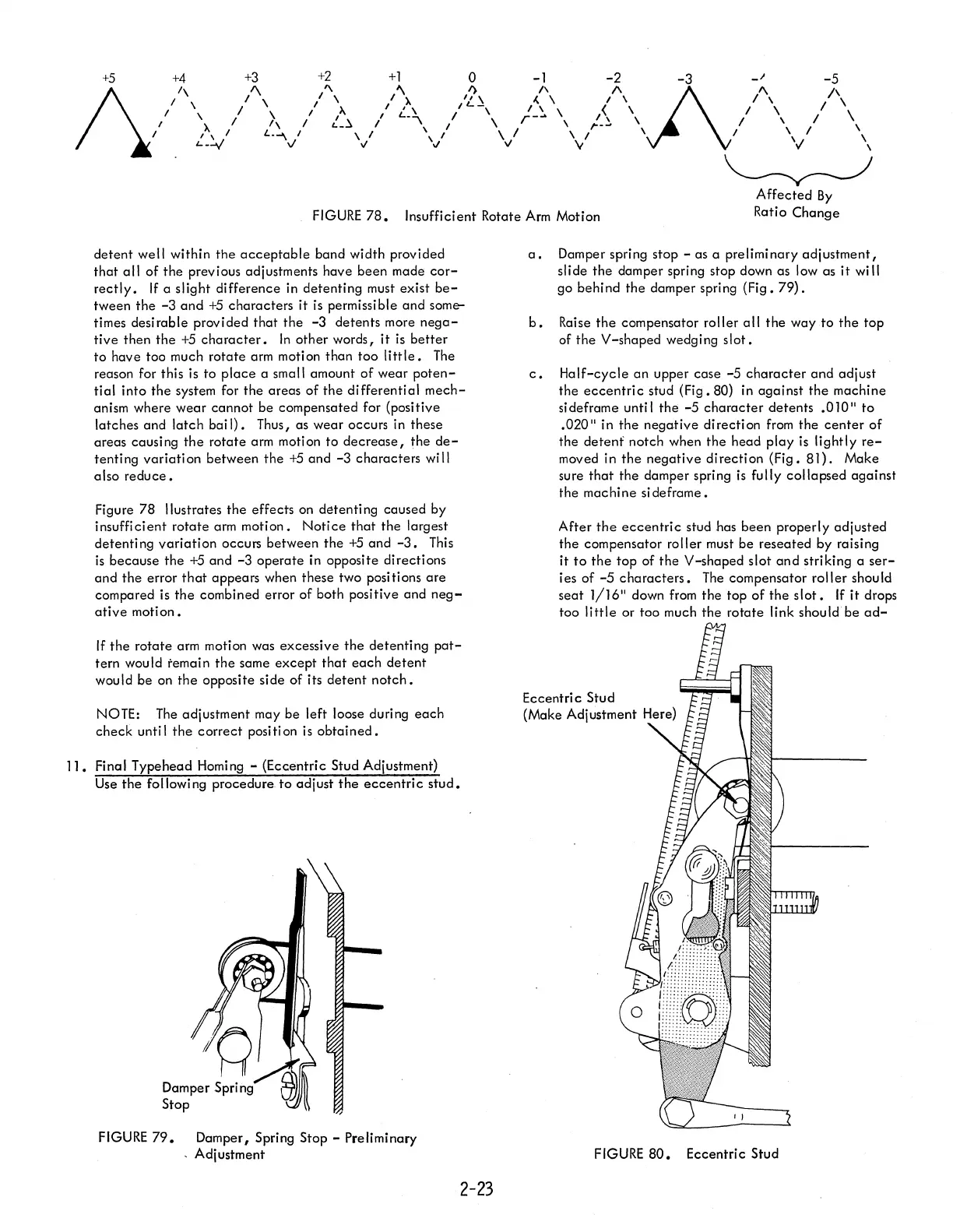

Figure 78 lIustrates the effects

on

detenting caused by

insufficient rotate arm motion.

Notice

that

the largest

detenting

variation

occurs between the

+5

and

-3.

This

is

because the

+5

and

-3

operate in opposite directions

and

the

error

that

appears when these two positions

are

compared

is

the

combined error of both positive and

neg-

ative

motion.

If

the

rotate

arm motion was excessive

the

detenting

pat-

tern would remain

the

same

except

that

each

detent

would be on

the

opposite side of its

detent

notch.

NOTE:

The

adjustment may be left loose during

each

check until

the

correct

position is

obtained.

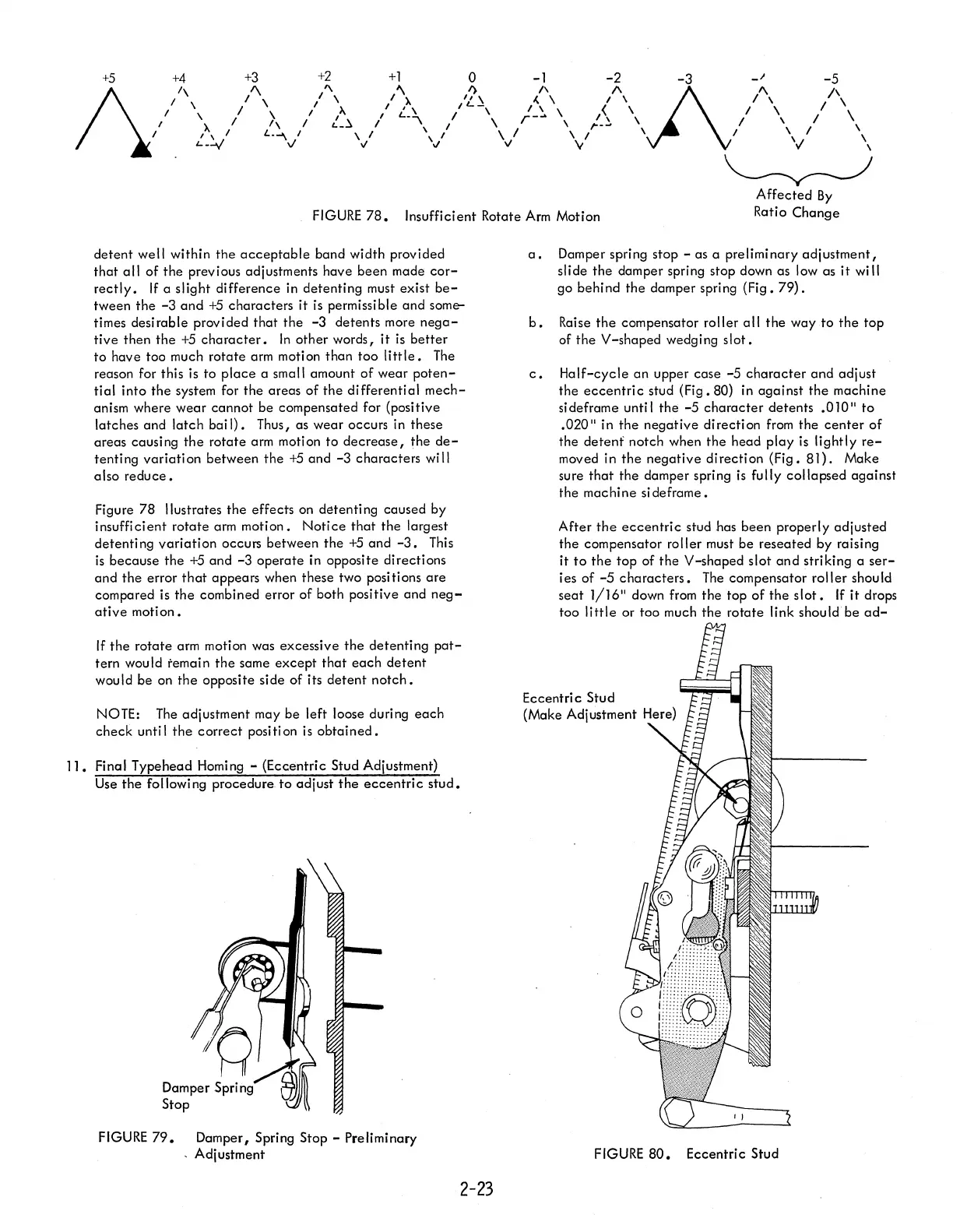

11. Final Typehead Homing - (Eccentric Stud Adjustment)

Use

the

following procedure

to

adjust

the

eccentric

stud.

FIGURE

79.

Damper, Spring Stop - Preliminary

,

Adjustment

2-23

a.

Damper spring stop - as a preliminary adjustment,

slide

the

damper spring stop down as low as

it

will

go behind the damper spring (Fig.

79).

b.

Raise

the

compensator roller

all

the

way

to

the

top

of

the

V-shaped wedging

slot.

c.

Half-cycle

an

upper case

-5

character

and

adjust

the

eccentric

stud (Fig. 80) in against

the

machine

si

deframe unti I the

-5

character

detents

.010"

to

.020" in

the

negative

direction

from

the

center

of

the

detenf

notch when the head

play

is

lightly

re-

moved in

the

negative

di

recti

on

(Fig.

81).

Make

sure

that

the damper spring

is

fully collapsed against

the machine

si

deframe.

After

the

eccentric

stud has been properly adjusted

the compensator roller must be reseated by raising

it

to

the

top of

the

V-shaped slot

and

striking a

ser-

ies of

-5

characters.

The

compensator roller should

seat

1/16"

down

from

the top

of

the

slot.

If

it

drops

too

little

or too much the rotate link should be

ad-

Eccentric Stud

(Make Adjustment Here)

FIGURE

80.

Eccentric Stud

Loading...

Loading...