rotate

character,

it

indicates

thot the

typehead

has

moved because of an

unbalanced condition between

the

positive and

negative

motions.

With

the

machine in the

half-cycled

position using

the

cancellation

method,

adjust

the

right hand member

of

the

balance

lever

left or right unti I

the

detenting

is

ex-

actly

as

it

is

when a

zero

rotate

character

is

half-cycled

normally. Changing

the

balance

lever adjustment will

not

appreciably

affect

the

detenting of

the

half-cycled

zero

rotate

character

(latched

home).

NOTE: The nut on

the

balance

lever screw can be left

loose

unti I

the

correct

adjustment

is

obtained.

Be

sure

not

to

move

the

adjustment when tightening

the

nut.

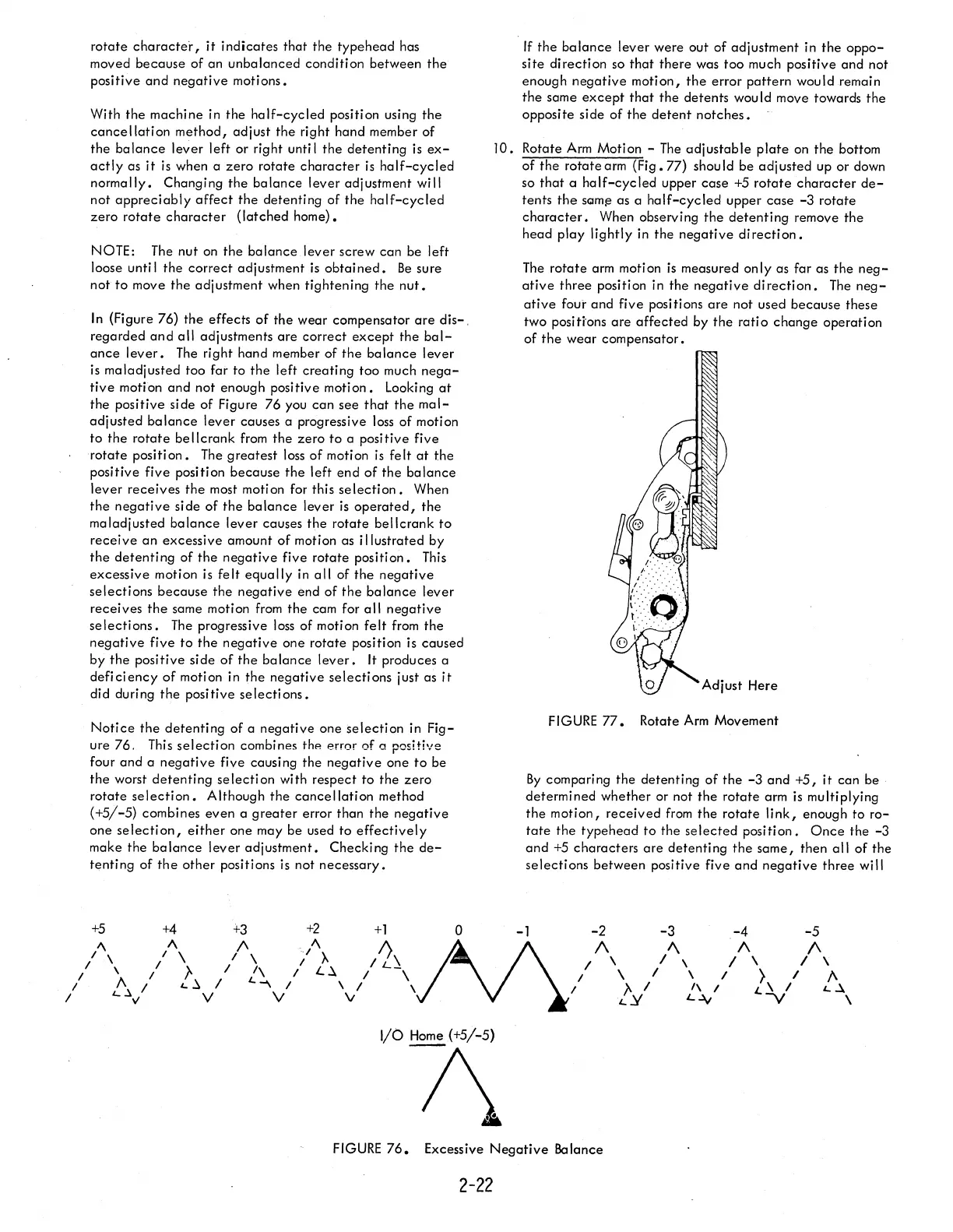

In

(Figure 76)

the

effects

of

the

wear compensator

are

dis-.

regarded

and

all

adjustments

are

correct

except

the

bal-

ance

lever.

The

right hand member of

the

balance

lever

is

maladjusted too far to

the

left creating too much

nega-

tive

motion and not enough positive motion. Looking

at

the positive side

of

Figure

76

you

can

see

that

the

mal-

adjusted

balance

lever causes a progressive

loss

of

motion

to

the

rotate

bellcrank

from

the

zero

to

a positive five

rotate

position.

The

greatest

loss

of

motion

is

felt

at

the

positive five position because

the

left

end

of

the

balance

lever

receives

the

most motion for this

selection.

When

the

negative

side of

the

balance

lever

is

operated,

the

ma

ladjusted ba lance

lever

causes

the

rotate

bellcrank

to

receive

an

excessive amount

of

motion as

illustrated

by

the

detenting

of

the

negative

five rotate position.

This

excessive motion

is

felt

equally

in

all

of

the

negative

selections

because

the

negative

end of

the

balance

lever

receives

the

same motion

from

the

cam for

all

negative

selections.

The

progressive

loss

of motion

felt

from

the

negative

five to

the

negative

one rotate position is caused

by

the

positive side

of

the

balance

lever.

It

produces a

deficiency

of

motion in

the

negative

selections just as

it

did during

the

positive

selections.

Notice

the

detenting

of a

negative

one

selection

in

Fig-

ure

76.

This

selection

combines

thp.

error

of

a positive

four and a

negative

five causing

the

negative

one

to

be

the

worst

detenting

selection

with respect to

the

zero

rotate

selection.

Although

the

cancellation

method

(+5/-5)

combines even a

greater

error than

the

negative

one

selection,

either

one may be used to

effectively

make

the

balance

lever adjustment. Checking

the

de-

tenting

of

the

other

positions

is

not

necessary.

+5

+4

+3

+2

+1

/'

/\

I \ I r

I A I

...

~

/

/

'-.:!:J../

V

/\

.1\

/2~

I

,

I'

}.

/

1\

I

L~

I

\

L"",\

I \

I

\

V

"

0

If

the

balance

lever were out

af

adjustment in

the

oppo-

site

direction so

that

there was too much positive and not

enough

negative

motion,

the

error

pattern

would remain

the

same

except

that

the

detents would move towards

the

opposite side

of

the

detent

notches.

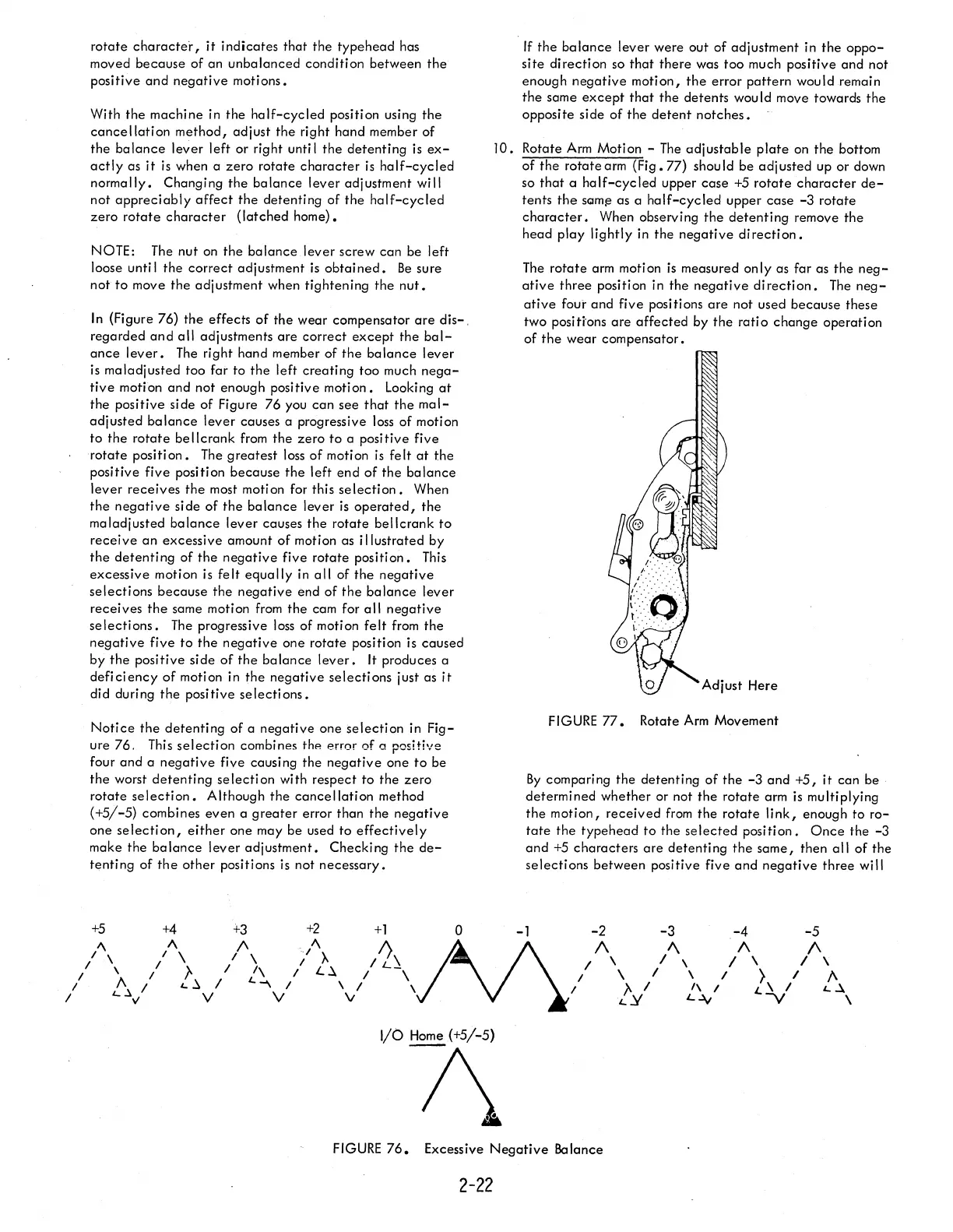

JO.

Rotate

Arm

Motion -

The

adjustable

plate

on

the

bottom

of

the

rotate

arm (Fig. 77) shou

Id

be adj usted up or down

so

that

a

half-cycled

upper case

+5

rotate

character

de-

tents

the

SQm~

as a

half-cycled

upper

case

-3

rotate

character.

When observing

the

detenting

remove

the

head play lightly in

the

negative

direction.

The

rotate

arm motion

is

measured only as far as

the

neg-

ative

three position in

the

negative

direction.

The

neg-

ative

foui' and five positions

are

not used because these

two

positi'ons

are

affected

by

the

ratio

change

operation

of

the

wear compensator.

FIGURE

77.

Rotate

Arm

Movement

By

comparing the detenting

of

the

-3

and

+5,

it can be .

determined whether or not

the

rotate arm

is

multiplying

the

motion,

received

from

the

rotate

link,

enough to

ro-

tate

the

typehead

to

the

selected

position.

Once

the

-3

and

+5

characters

are

detenting

the

same,

then

all

of

the

selections

between positive five

and

negative

three will

-1 -2 -3

.-4

-5

1\

/,

I

\

/

I

\

I

[y

/

/\

f\.

\ / \ / \

\ / } / A

1\

I L \ / L. ~

L~

-y

\

VOH7\

FIGURE

76.

Excessive

Negative

Balance

2-22

Loading...

Loading...