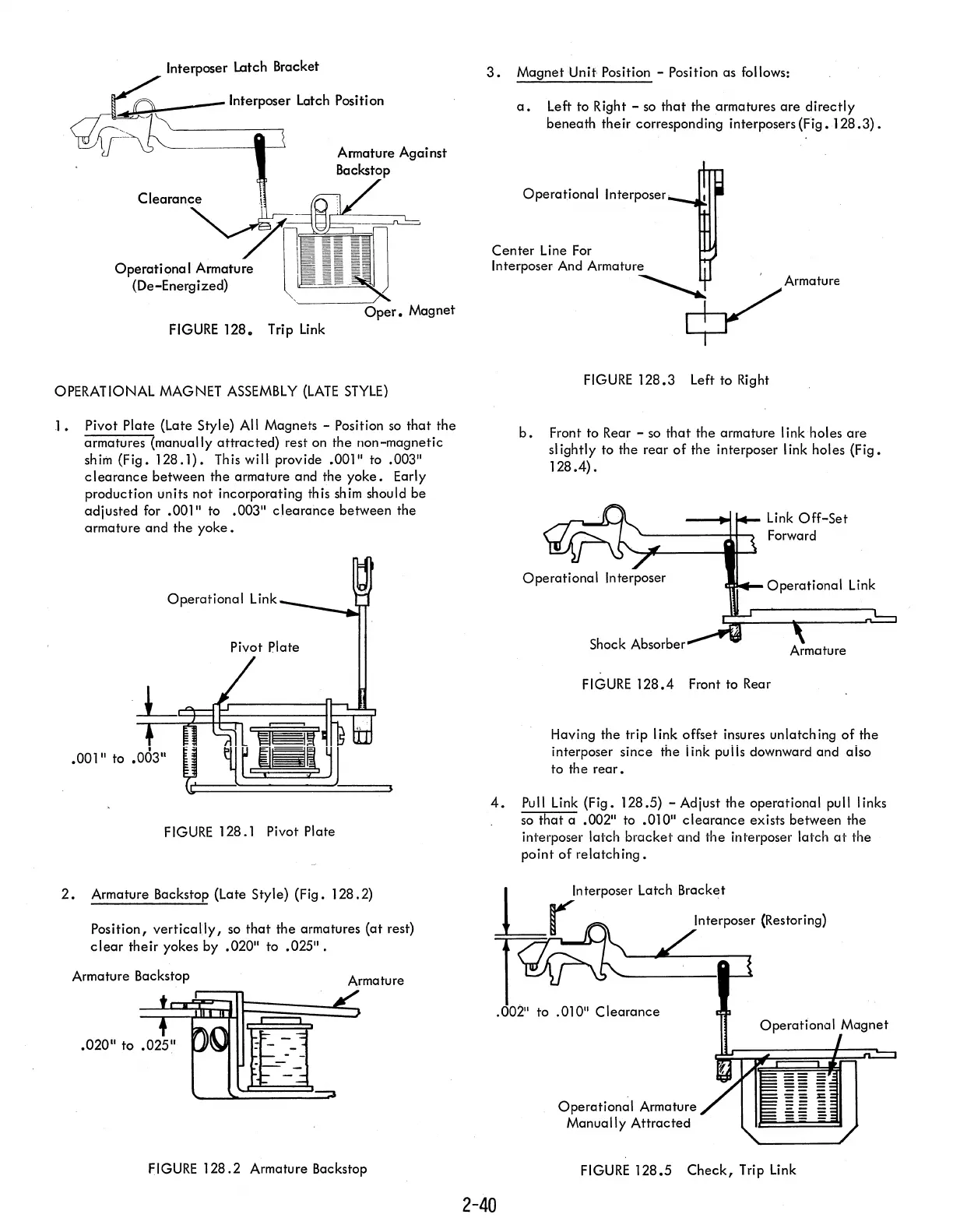

Interposer Latch Bracket

--,~~~~

___

Interposer Latch Position

Operational

Armature

(De-Energized)

FIGURE 128. Trip

Link

OPERATIONAL MAGNET

ASSEMBLY

(LATE

STYLE)

1.

Pivot

Plate

(Late Style) All Magnets - Position

so

that

the

armatures (manually

attracted)

rest on the

non-magnetic

shim

(Fig.

128.1). This will provide .001" to .003"

clearance

between

the

armature and the

yoke.

Early

production units

not

incorporating this shim should

be

adjusted

for .001" to .003"

clearance

between

the

armature

and

the

yoke.

Operational

Link

~_~

Pivot Plate

.001" to .003"

FIGURE

128.1 Pivot Plate

2.

Armature Backstop (Late Style)

(Fig.

128.2)

Position,

vertically,

so

that

the

armatures

(at

rest)

clear

their

yokes by .020"

to

.025".

Armature Backstop

Armature

fiGURE 128.2 Armature Backstop

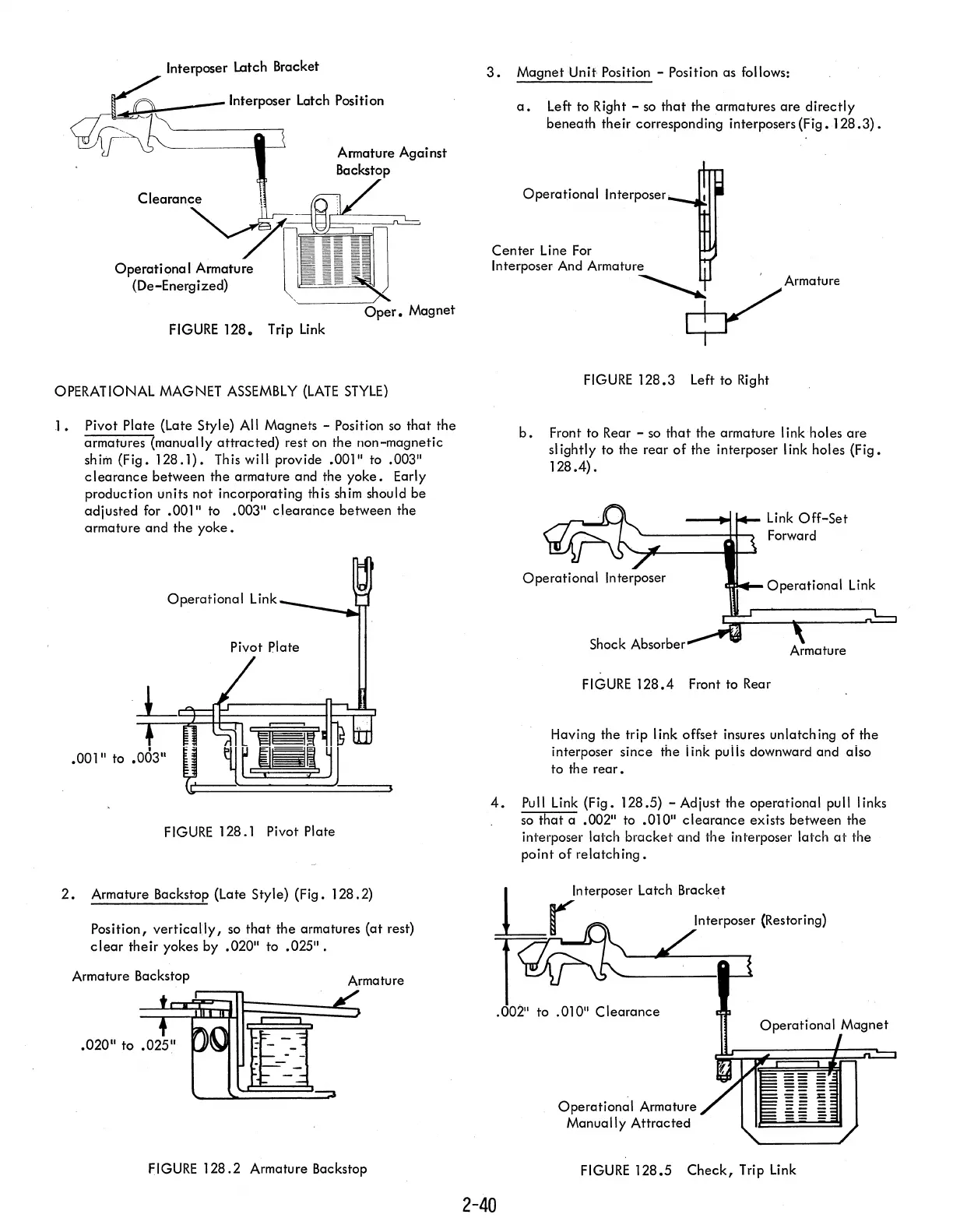

3.

Magnet

Unit Position - Position as follows:

a.

Left to Right -

so

that

the armatures

are

directly

beneath

their

corresponding interposers

(Fig.

128.3).

Operational

Interposer

FIGURE

128.3 Left to Right

b.

Front to Rear -

so

that

the armature I ink holes

are

slightly

to the

rear

of

the interposer I ink holes

(Fig.

128.4).

Link

Off-Set

Shock Absorber

FIGURE

128.4 Front to Rear

Having the trip

I ink offset insures unlatch ing

of

the

interposer

since

the iink puiis downward and aiso

to

the

rear.

4.

Pull Link (Fig. 128.5) - Adjust the

operational

pull links

so

that

a .002" to .010"

clearance

exists between

the

interposer latch

bracket

and

the

interposer latch

at

the

point

of

relatch

ing.

2-40

Operational

Armature

Manually

Attracted

FIGURE

128.5

Check,

Trip Link

Loading...

Loading...