Adjust

Clearance

For

.015"

To

.020"

Actuating

Arm

Stud

Clutch

Actuating

Arm----~......;..:..:...:......,,:..:...:......:..:..:..:,;.

""'-'---

FIGURE

144.

Carrier

Return

Actuating

Arm

Adj ustment

Clutch

Spring

NOTE:

In

no case should the shoe to

clutch

spring

clearance

be less than

.015".

6.

Overbank Adiustment

"'"

\"/ith

the

CCidei

held fully to the

left

against

the

margin

stop,

a

clearance

of

.003"

to

.008" should

exist

between the working surfaces

of

the

escapement

pawl and the escapement

rack

tooth (Fig

...

145). Adjust the

left-hand

margin rock bushing

to

ob-

tain

this

condition

(Fig.

146).

FIGURE

145.

Escapement Pawl

Check

The overbank adjustment insures

that

the

escapement

pawl

wi

II

enter

the

correct

escapement rack tooth

when

the

carrier

return

clutch

is

unlatched

at

the'

left

margin.

The

adjustment may be observed

from

the

top

with

the

platen

and

deflector

removed

and

the

left margin stop positioned toward

the

middle of

the

rock.

The overbank may also

be

adjusted by

ad-

justing

the

lTD rgin rock bushing

to

clear

the nylon

washer on

the

margin

rack

by

.025"

to

.030"

with

the

carrier

resting

at

the

left

margin.

The right hand

margin rack

eccentric

should be loose when making

this adjustment

(Fig.

146) so

that

the

left margin

stop will be

against

the

stop latch on

the

carrier.

The

.025"

to

.030"

compensates for

the

.022"

float-

ing

action

in

the

escapement

pawl.

(The

correct

adjustment for the margin rack

eccentric

is covered

under the Margin

Control

section.)

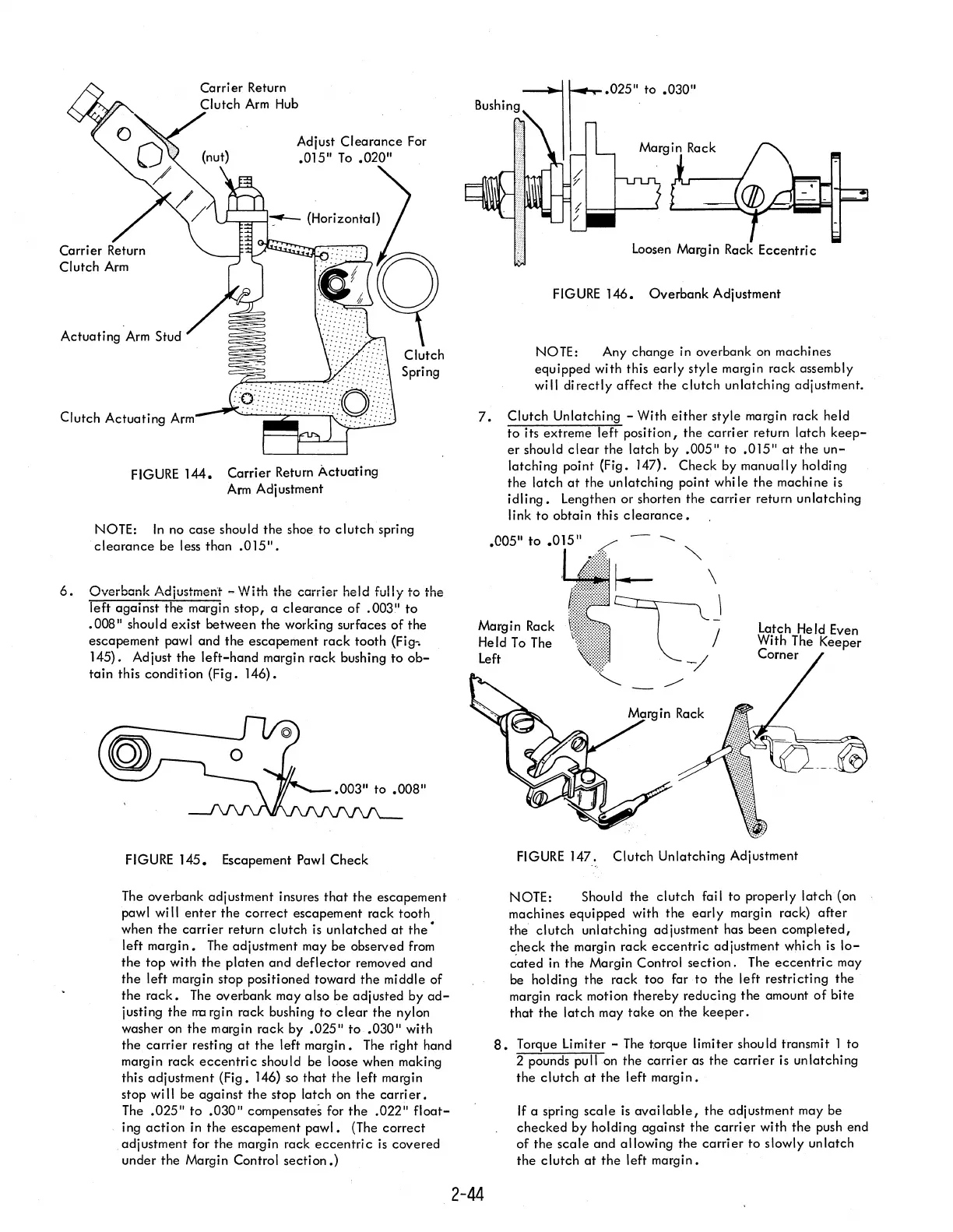

FIGURE

146.

Overbank

Adjustment

NOTE: Any change in overbank on machines

equipped with this

early

style margin rock assembly

will

directly

affect

the

clutch

unlatching adjustment.

7.

Clutch Unlatching - With

either

style margin rock held

to

its extreme left position, the

carrier

return latch

keep-

er

should

clear

the latch by

.005"

to

.015"

at

the

un-

latching point (Fig. 147).

Check

by manually holding

the

latch

at

the

unlatching point while

the

machine

is

idling.

Lengthen or shorten the

carrier

return unlatching

link

to

obtain

this

clearance.

---...

"'"

f-- \

Margin Rack

Held

To

The

Left

""L\

I

"::::,,:,

-/

-

Latch Held Even

With The Keeper

Corner

2-44

FIGURE

147. Clutch Unlatching Adjustment

NOTE: Should

the

clutch

fail to properly

latch

(on

machines equipped with

the

early

margin rock)

after

the

clutch

unlatching adjustment has been

completed,

check

the margin rack

eccentric

adjustment which

is

10-

~ated

in

the

Margin Control

section.

The

eccentric

may

be

holding the rock too far

to

the

left

restricting the

margin

rack

motion

thereby

reducing

the

amount

of

bite

that

the

latch

may

take

on the

keeper.

8.

Torque Limiter -

The

t.orque limiter should transmit 1

to

2 pounds pull on the

carrier

as the

carrier

is unlatching

the

clutch

at

the

left margin.

If

a spring

scale

is

available,

the

adjustment may be

checked

by holding against the

carrier

with the push end

of

the

scale

and allowing

the

carrier

to slowly unlatch

the

clutch

at

the

left margin.

Loading...

Loading...