.005"

to

.020"

Clutch Latch

Eccentri c

---~'-J

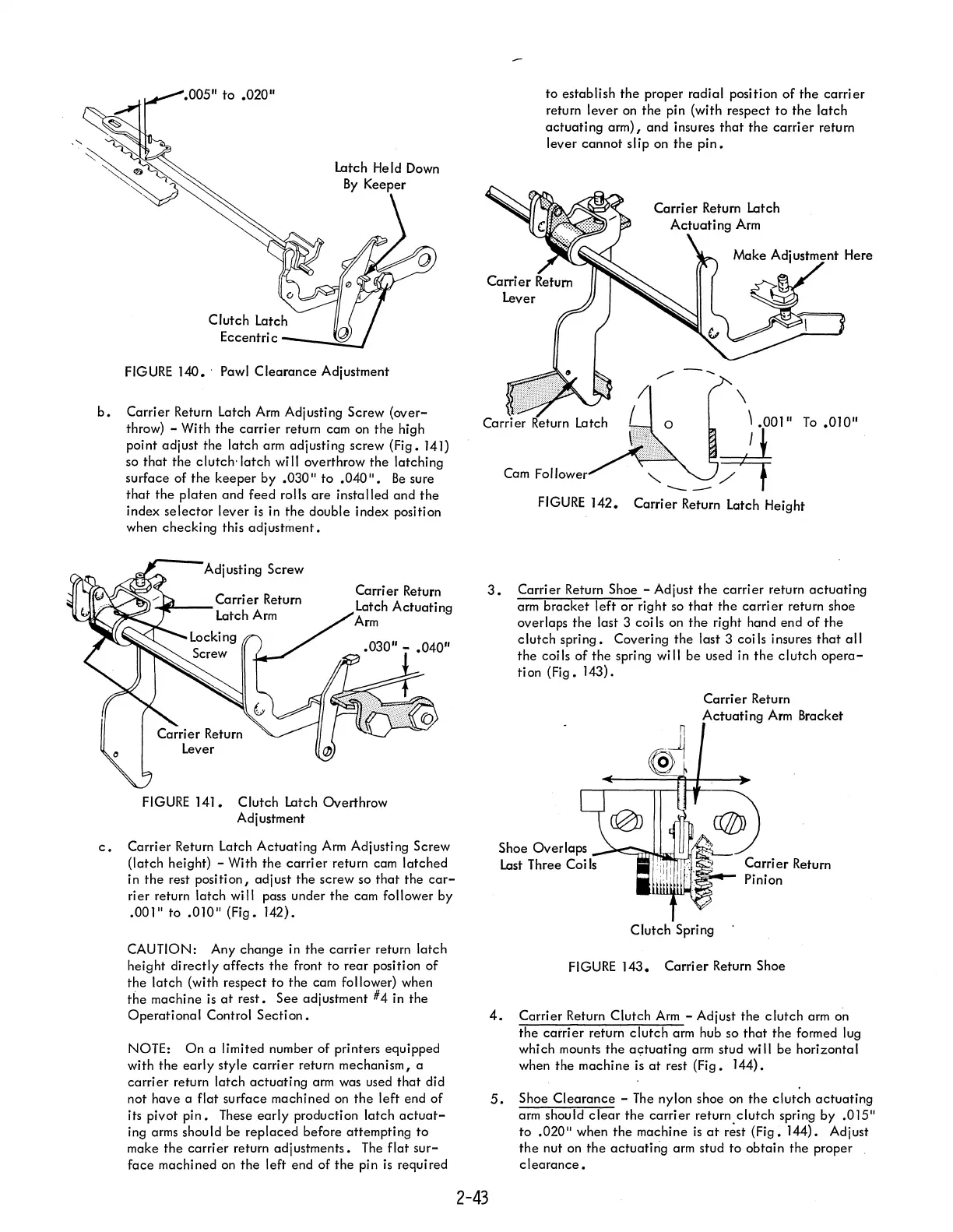

FIGURE

140

• . Pawl

Clearance

Adjustment

b.

Carrier Return Latch

Arm

Adjusting Screw (over-

throw) - With

the

carrier

return cam on

the

high

point adjust the latch arm adjusting screw (Fig.

14

I)

so

that

the clutch-Iotch will overthrow

the

lotching

surface of

the

keeper by

.030"

to

.040".

Be

sure

that

the

platen and feed rolls

are

installed

and

the

index

selector

lever is in

the

double index position

when checking this adjustr;'ent.

Adj usti

ng

Screw

Carrier

Return

"'"---Latch

Arm

FIGURE

141.

Clutch Latch Overthrow

Adjustment

c.

Carrier Return Latch Actuating

Arm

Adjusting Screw

(latch height) - With the

carrier

return cam latched

in

the

rest position, adjust the screw so

that

the

car-

rier return latch will pass under the cam follower by

.001"

to

.0lO"

(Fig. 142).

CAUTION: Any change in

the

carrier

return latch

height

directly

affects

the

front to rear position

of

the

lotch (with respect to

the

cam follower) when

the

machine is

at

rest.

See

adjustment #4 in the

Operational

Control

Section.

NOTE:

On

a limited number of printers equipped

with

the

early

style

carrier

return mechanism, a

carrier

return latch

actuating

arm was used

that

did

not have a flat surface machined

on

the

left end

of

its pivot

pin.

These

early

production latch

actuat-

ing arms should be

replaced

before attempting

to

make

the

carrier

return adjustments.

The

flat

sur-

face

machined on

the

left end

of

the

pin

is

required

to establish

the

proper radial position

of

the

carrier

return

lever

on

the

pin (with respect

to

the

latch

actuating

arm), and insures

that

the

carrier

return

lever cannot slip on

the

pin.

001"

To

.010"

Cam

Fol

FIGURE

142.

Carrier Return Latch Height

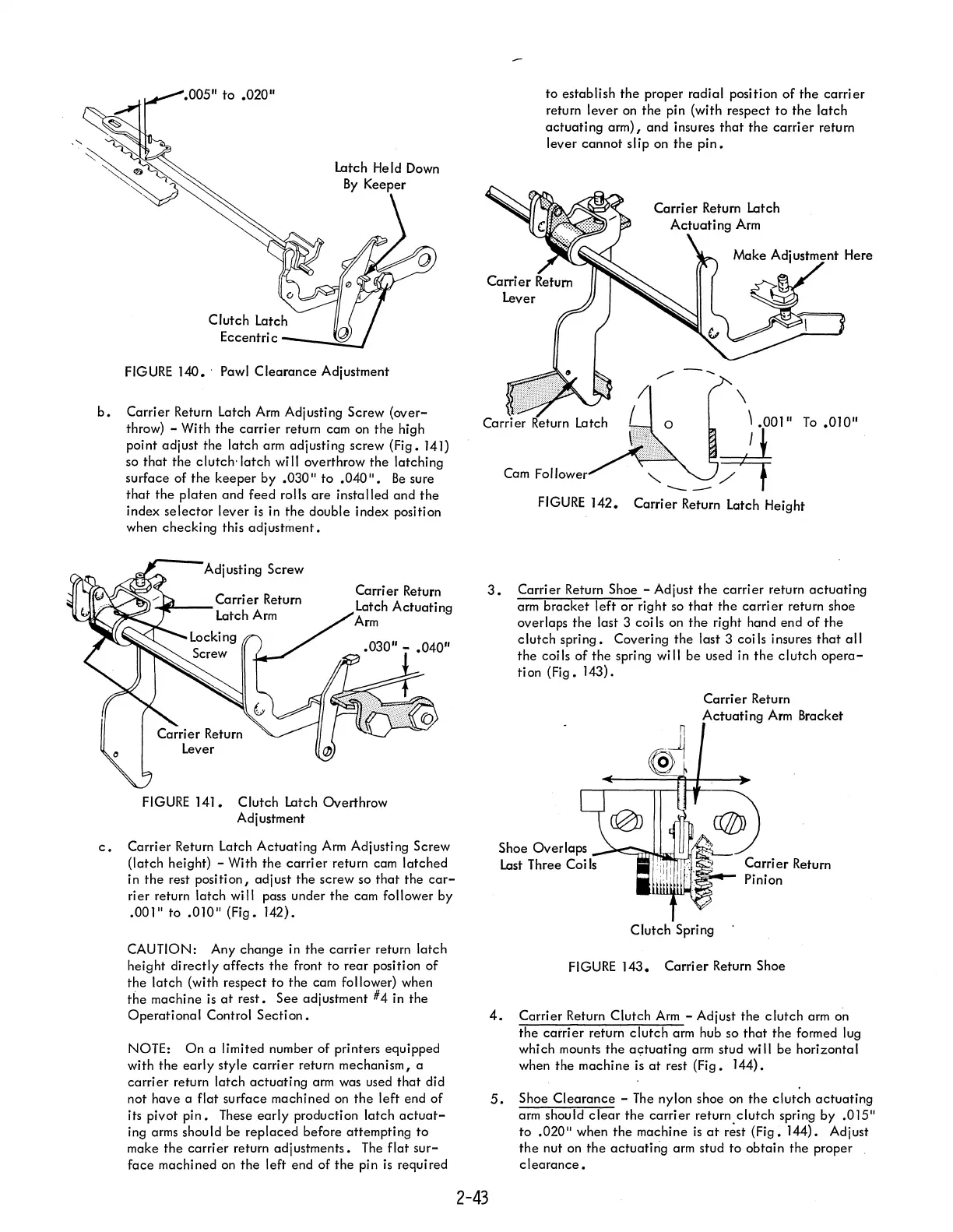

3.

Carrier Return Shoe - Adjust

the

carrier

return

actuating

arm

bracket

left

or

right so

that

the

carrier

return shoe

overlaps

the

last 3 coi

Is

on

the

right hand end

of

the

clutch spring. Covering

the

last 3 coils insures

that

all

the

coils

of

the

spring will

be

used in

the

clutch

opera-

tion (Fig. 143).

2-43

Carrier

Return

Actuating

Arm

Bracket

Shoe Overlaps

-~:..:::::u:rrMllirl':

Last

Three Coi

Is

Clutch Spring

FIGURE

143.

Carrier

Return Shoe

4.

Carrier Return Clutch

Arm

- Adjust the

clutch

arm

on

the

carrier

return

clutch

arm hub so

that

the formed lug

whi ch mounts the ac;:tuati

ng

arm stud

wi

II

be hori zonta I

when the machine is

at

rest (Fig. 144).

5.

Shoe

Clearance

-

The

nylon shoe

on

the

clutch

actuating

arm should

clear

the

carrier

return clutch spring by .015"

to

.020"

when

the

machine

is

at

r~st

(Fig.

144). Adjust

the

nut on

the

actuating arm stud

to

obtain the proper

clearance.

Loading...

Loading...