8.

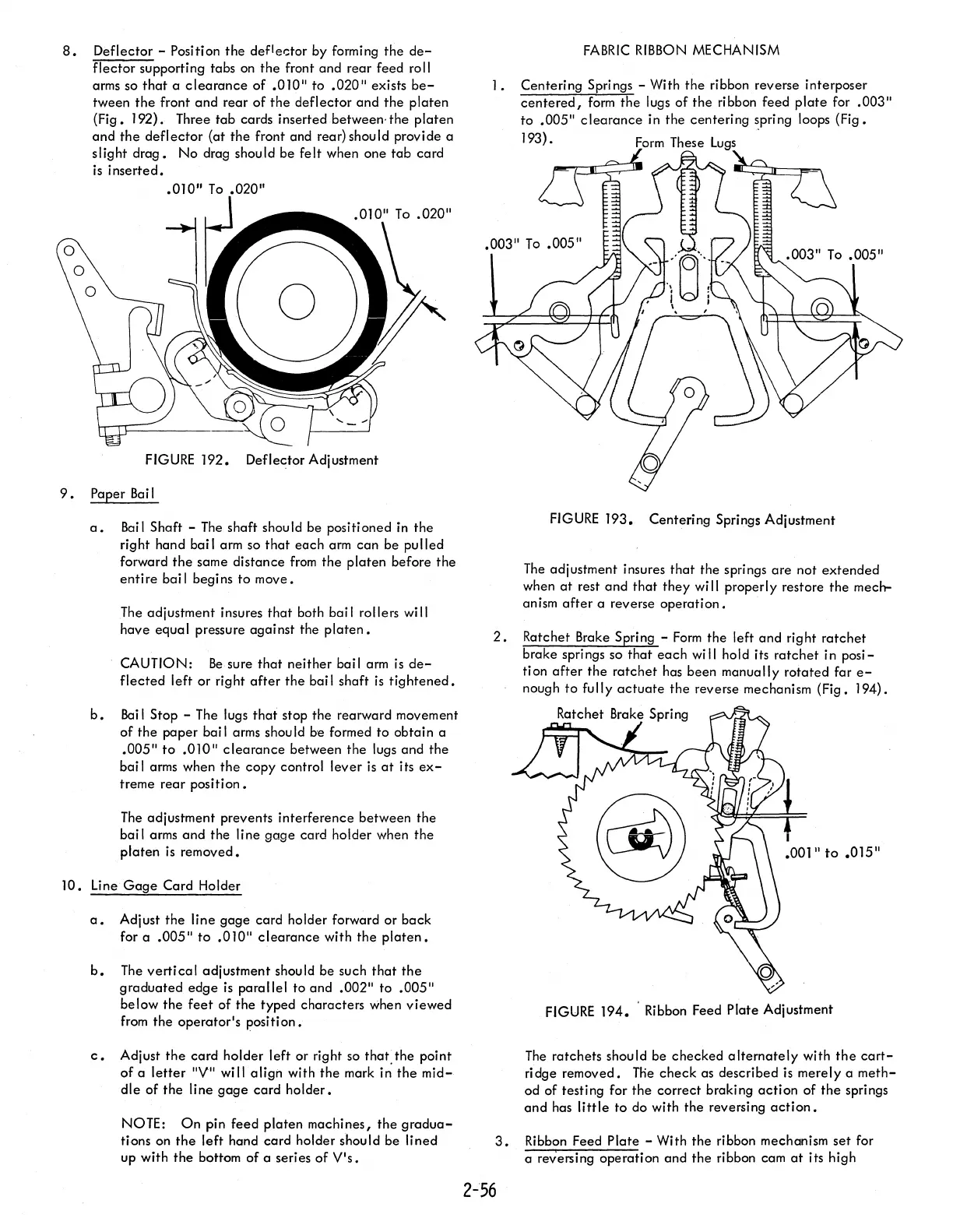

Deflector - Position

the

def1e.;:tor by forming

the

de-

flector

supporting tabs on

the

front and

rear

feed roll

arms so

that

a

clearance

of

.010" to .020" exists

be-

tween

the

front

and

rear

ofthe

deflector

and

the

platen

(Fig.

192). Three

tab

cards inserted between·

the

platen

and

the

deflector

(at

the

front and rear) should provide a

slight

drag.

No

drag should be

felt

when one

tab

card

is

inserted •

• 010"

To

.020"

FIGURE

192. Deflector Adjustment

9.

Paper

Bai

I

a.

Bail

Shaft -

The

shaft should be positioned in

the

right hand bai I arm so

that

each

arm

can

be

pulled

forward

the

same

distance

from

the

platen

before

the

entire

bail begins to move.

The adjustment insures

that

both bai I rollers

wi

II

have equal pressure against the

platen.

CAUTION:

Be

sure

that

neither bail arm

is

de-

flected

left

or

right

after

the

bai I shaft

is

tightened.

b.

Bai

I Stop - The lugs

that

stop

the

rearward movement

of

the

paper bail arms should be formed to obtain a

.005"

to

.010"

clearance

between

the

lugs and

the

bai I arms when

the

copy control lever

is

at

its

ex-

treme

rear

position.

The

adjustment prevents interference between

the

bai I arms

and

the

Ii ne

gage

card holder when

the

platen

is

removed.

JO.

Line

Gage

Card Holder

a.

Adjust

the

line

gage

card holder forward

or

back

for a .005"

to

.010"

clearance

with

the

platen.

b.

The

verti

ca

I adjustment shou

Id

be such

that

the

graduated

edge

is

parallel

to and .002" to .005"

below

the

feet

of

the

typed characters when

viewed

from

the

operator's

position.

c.

Adjust

the

card

holder left or right so

that,the

point

of

a

letter

"V" will

align

with

the

mark in

the

mid-

dle

of

the

line

gage

card

holder.

NOTE:

On

pin feed

platen

machines,

the

gradua-

tions on

the

left hand card holder should be lined

up with

the

bottom

of

a series

of

V's.

FABRIC

RIBBON

MECHANISM

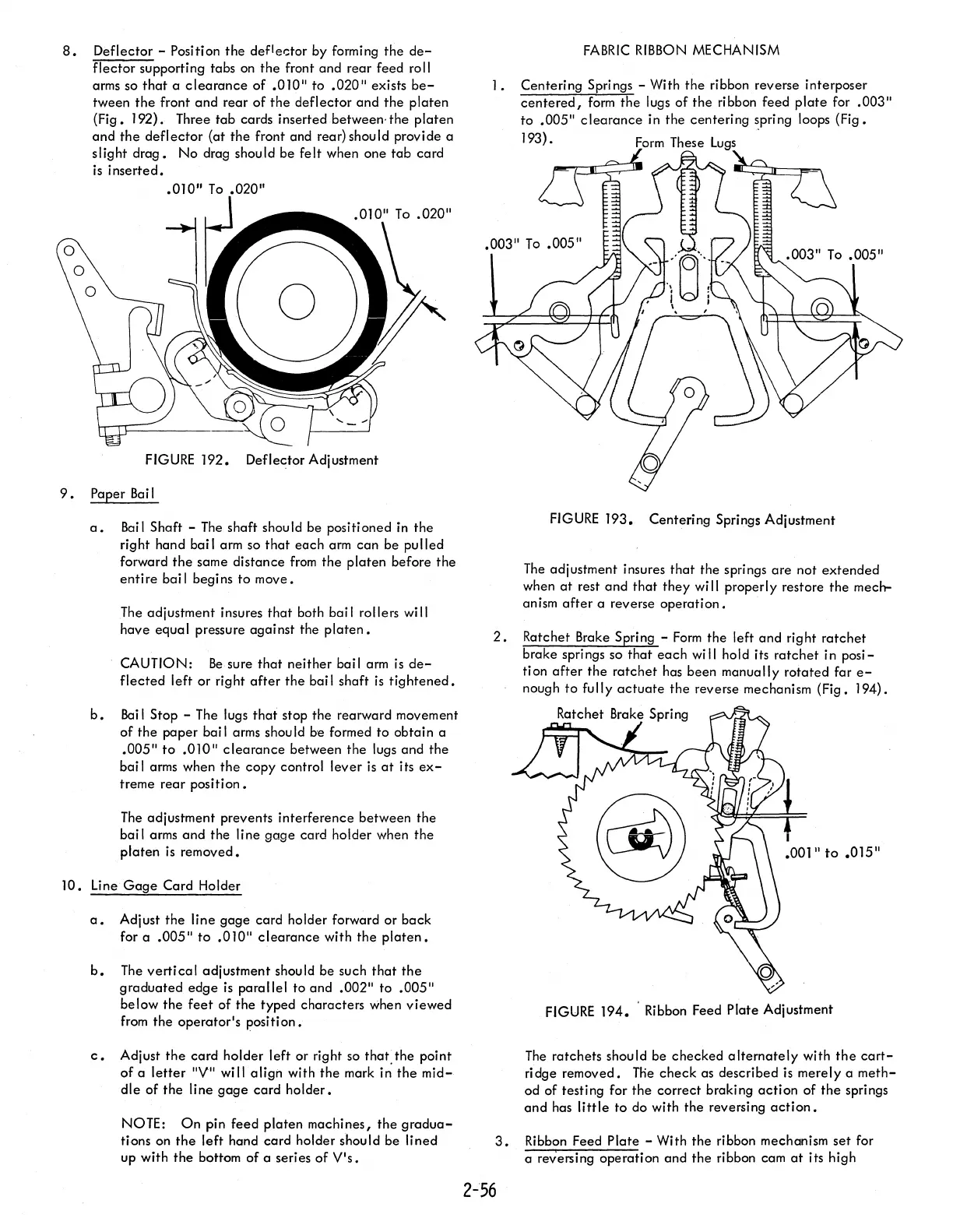

I.

Centering Springs - With

the

ribbon reverse interposer

centered,

form

the

lugs

of

the

ribbon feed

plate

for .003"

to

.005"

clearance

in the centering spring loops

(Fig.

193).

Form

These lugs .

FIGURE

193. Centering Springs Adjustment

The

adjustment insures

that

the springs

are

not

extended

when

at

rest and

that

they

wi

II

properly restore

the

mech-

anism

after

a reverse

operation.

2.

Ratchet Brake Spring -

Form

the

left and right

ratchet

brake springs so

that

each

wi

II

hold its

ratchet

in

posi-

tion

after

the

ratchet

has been manually

rotated

far

e-

nough

to

fully

actuate

the

reverse mechanism (Fig. 194).

Ratchet Brake Spring

I

.001"

to

.015"

FIGURE

194. Ribbon Feed Plate Adjustment

The

ratchets should be

checked

alternately

with

the

cart-

ridge removed.

The

check

as described

is

merely

a

meth-

od of testing for

the

correct braking

action

of

the

springs

and

has

little

to do with

the

reversing

action.

3.

Ribbon Feed Plate - With

the

ribbon mechanism

set

for

a reversing operation and

the

ribbon cam

at

its high

2-56

Loading...

Loading...