MEDIAJET – Operating instructions V09 Operation

40 INTEGRA Biosciences AG

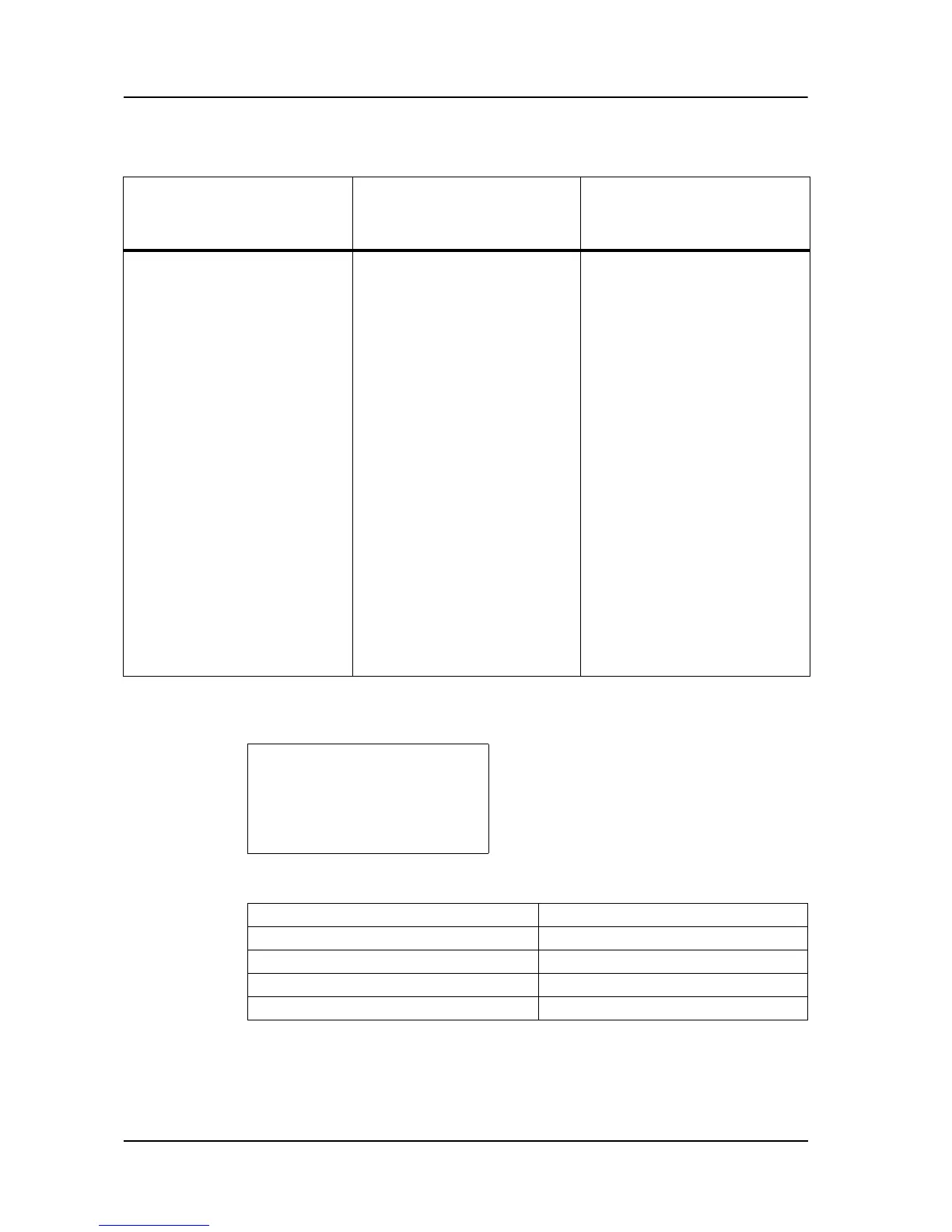

The following data (example) is printed out:

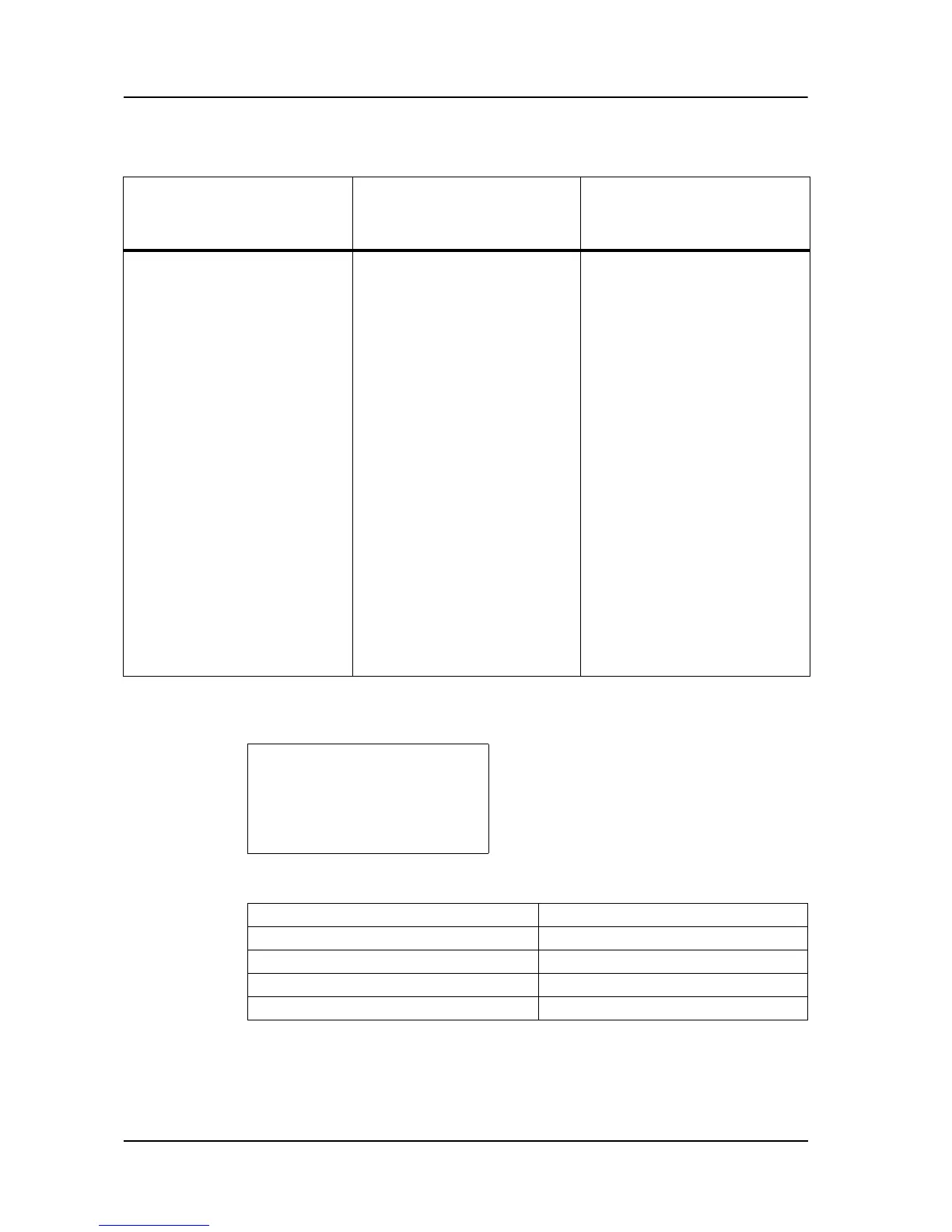

In the SYSTEM PARAMETERs, the possibility exists of carrying out the

following test print:

The RS232(2) Interface settings are fixed as follows:

Following calibration When starting the filling

process

Following completion of the

filling process

========================

MEDIAJET (SN:12345678)

***Calibration done

Time: hh:mm

Date: dd.mm.yyyy

========================

========================

MEDIAJET (SN:12345678)

***Start Filling Process

Time: hh:mm

Date: dd.mm.yyyy

***Program Settings

Name: TEST

Number of dishes: 360

Volume: 18.0 ml

Pump speed: 60 %

Anti-drip: ON

Pause time: 0.0 s

Dish height: 15.7 mm

Rotor move: NORMAL

Cont. filling: OFF

Shaker level: OFF

Batch mode: OFF

Biplate: ON

***System Parameter

UV-Lamp: OFF

Cooler: OFF

========================

========================

MEDIAJET (SN:12345678)

***End Filling Process

Time: hh:mm

Date: dd.mm.yyyy

***Program Settings

Name: TEST

Dishes filled:

10 of 360

Volume: 18.0 ml

Pump speed: 60 %

Anti-drip: ON

Pause time: 0.0 s

Dish height: 15.7 mm

Rotor move: NORMAL

Cont. filling: OFF

Shaker level: OFF

Batch mode: OFF

Biplate: ON

Turbo mode: ON

========================

========================

MEDIAJET (SN:12345678)

***Test Printout

LEFT RIGHT

123456789012345678901234

========================

Transmission Speed 9600 bps

Databits 8 bits

Partity No

Stopbits 1

Handshake X ON / X OFF

Loading...

Loading...