Intermec EasyCoder PF2i, PF4i, and PF4i Compact Industrial—Service Manual 97

Chapter 7—Print Mechanism

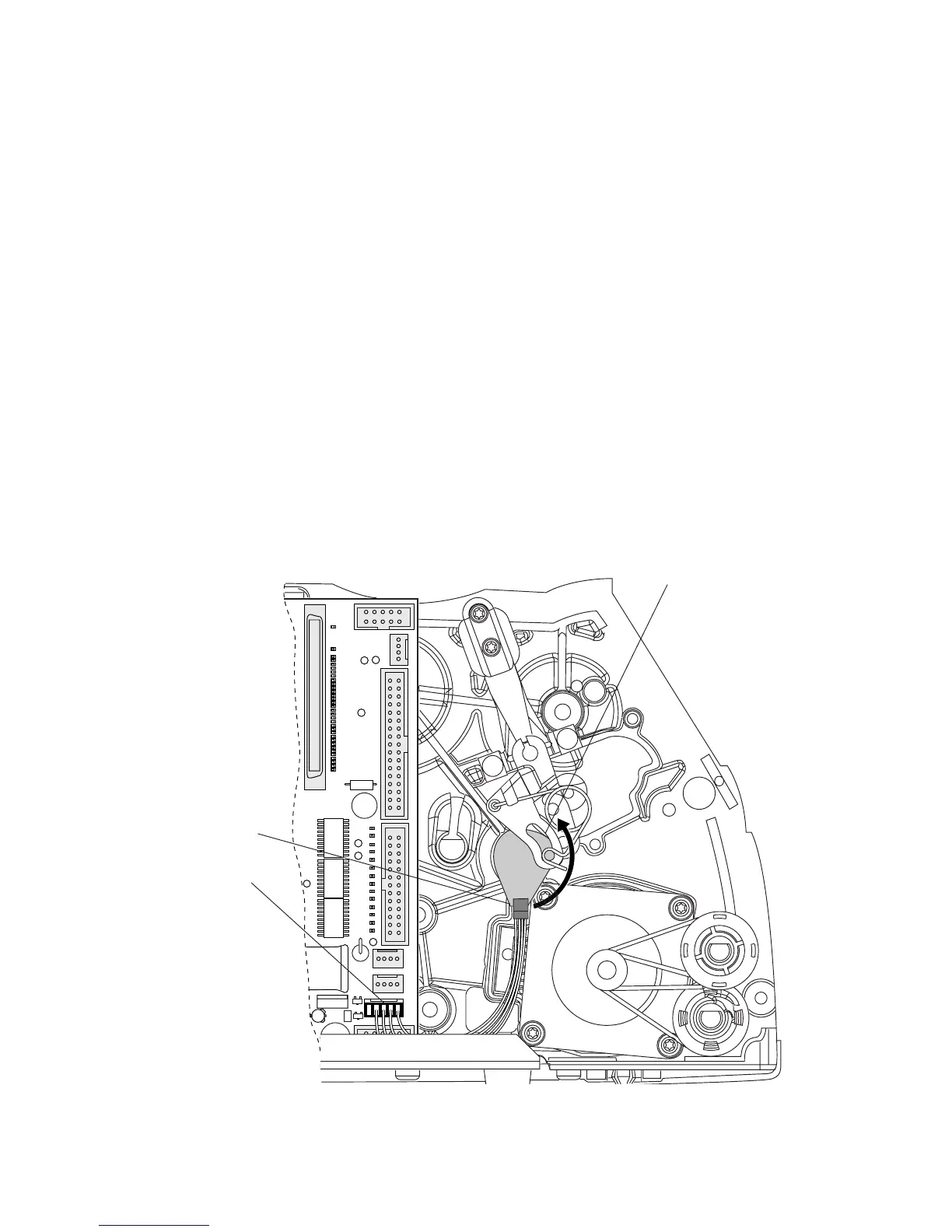

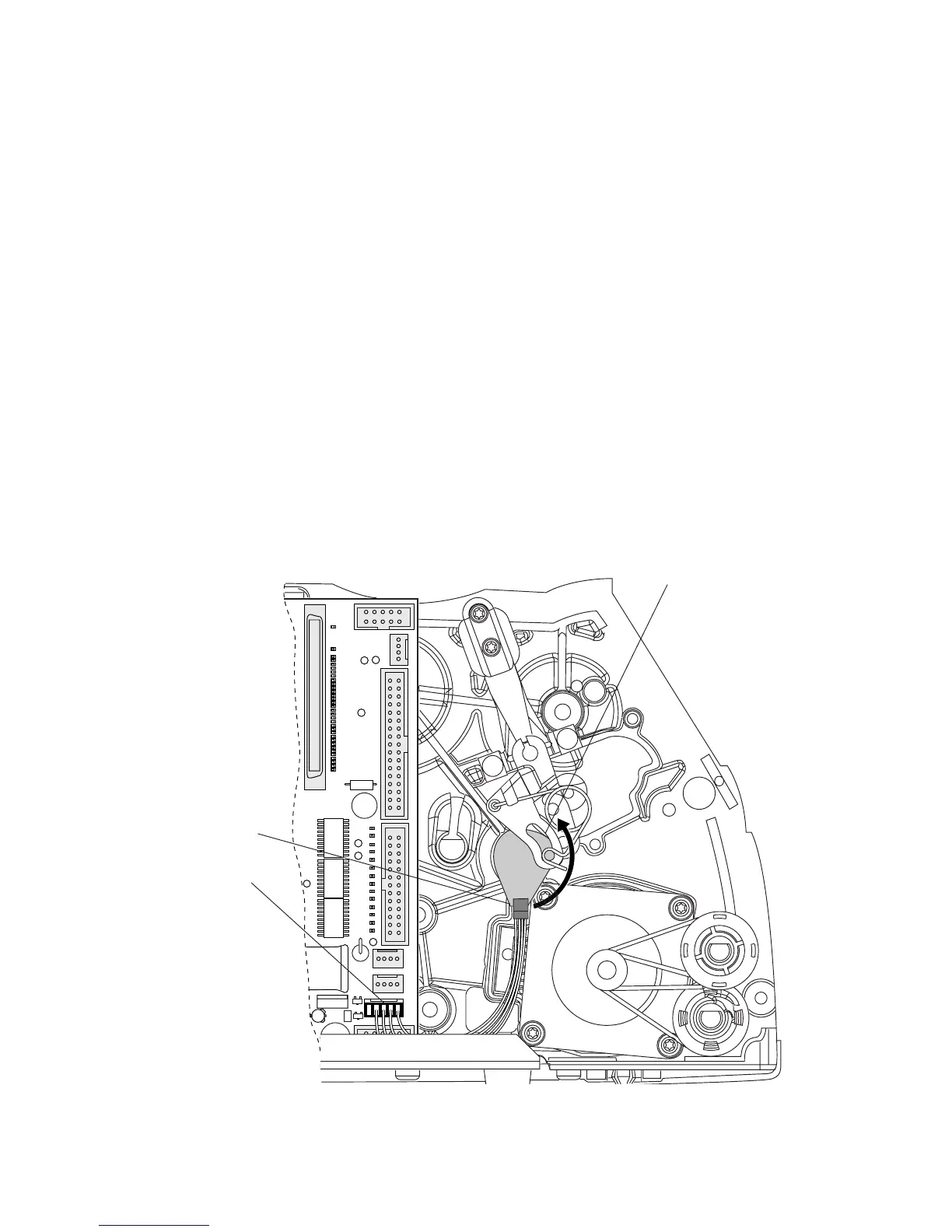

J84

J58

HEADLIFT

7.7 Headlift Sensor

Description

The purpose of the headlift sensor is to detect whether the printhead is

raised or lowered. To avoid the risk of overheating the printhead dots,

printing cannot be performed when the sensor detects that the printhead

is raised (the media serves to cool the printhead). An ever so slightly raised

printhead would also impair the printout quality. Thus, it is important that

the printhead is properly engaged and a suffi cient pressure is applied before

the sensor detects a “Closed” condition.

The sensor is fi tted using a barbed shaft that is pressed into a hole in the

center section. The sensor consists of a light-emitting diode and a photo-

electric sensor with housing and cables. The headlift sensor is connected to

J58 (marked “HEADLIFT”) on the CPU board.

A beam of light is constantly transmitted from the diode. When the

printhead is in closed position, the light beam is interrupted by an angular

plate at the end of the crank shaft. As soon as the headlift lever is activated,

and even before the printhead starts to raise, the plate is moved out of

the sensor gap and the sensor can detect the light beam. This condition

is managed by the fi rmware. In Fingerprint, an error message (1022

“Head Lifted”) will be returned if you try to print a label. In IPL, the error

message “Print Head UP/Press Feed” is displayed.

Plate on crank shaft

(printhead lowered)

Headlift sensor

Connect here!

To improve visibility, no transfer ribbon mechanism is shown.

Loading...

Loading...