Intermec EasyCoder PF2i, PF4i, and PF4i Compact Industrial—Service Manual 63

Chapter 6—Transfer Ribbon Mechanism

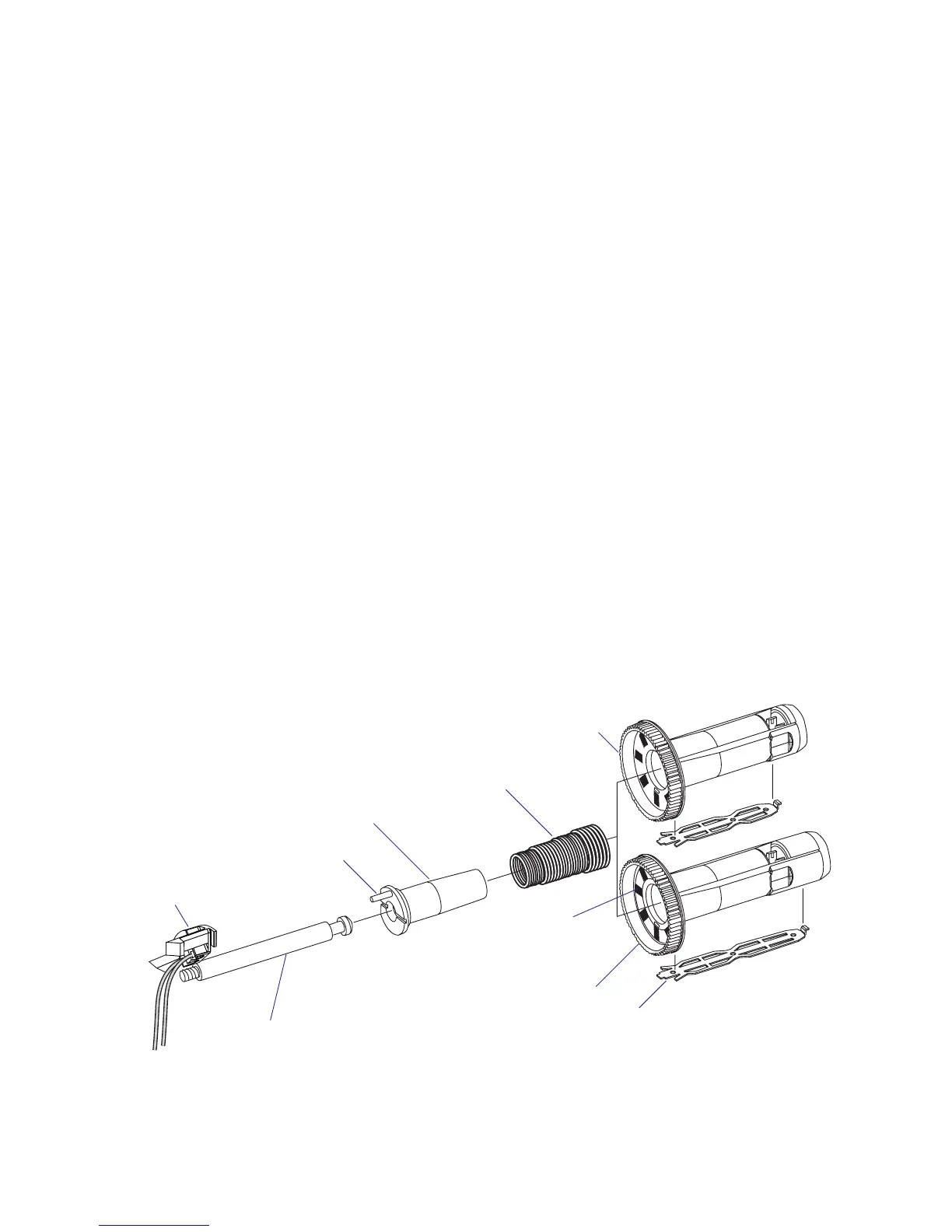

6.2 Ribbon Supply Unit

Description

The ribbon supply unit accommodates the supply of thermal transfer

ribbon. For troublefree printing, use ribbons recommended by Intermec.

Ribbon Specifications

Width (PF2i): 25 to 60 mm (1 to 3.36 in.)

Width (PF4i & PF4i CI): 25 to 110 mm (1 to 4.33 in.)

Roll diameter (outer), max.: 62 mm (2.44 in.)

Roll core diameter (inner): 25.4 mm (1.00 in.)

Ribbon length, max.: approx. 200 m (650 ft)

The unit is designed to keep the ribbon tight all the time in order to avoid

wrinkling and creases, which would ruin the printout. It consists of a shaft,

screwed into the center section, on which a bobbin is snap-locked. Inside

the bobbin is a hub with a tab that engages a hole in the center section and

a spring clutch. The bobbin is fi tted with a plate that holds the cardboard

core of the ribbon roll.

Inside the inner end of the bobbin is a pattern of refl ecting and non-

refl ecting sectors by means of which the ribbon sensor can detect the rota-

tion of the bobbin.

When the bobbin is rotated, the spring clutch is unwound and tries to pull

the ribbon back onto the roll. As the pulling force increases, the clutch

starts to slip and the ribbon can be unwound while still being kept tight.

The bobbin can rotate in both directions. Thus, ribbons wound with the

ink-coated side facing either inwards or outwards can be used.

Ribbon

sensor

Hub

Tab

Spring clutch

Bobbin (PF2i)

Bobbin plate

Detection pattern

Shaft

Bobbin (PF4i)

Loading...

Loading...