6A1 – 60 4JB1/4JB1T/4JB1TC/4JG2 - ENGINE

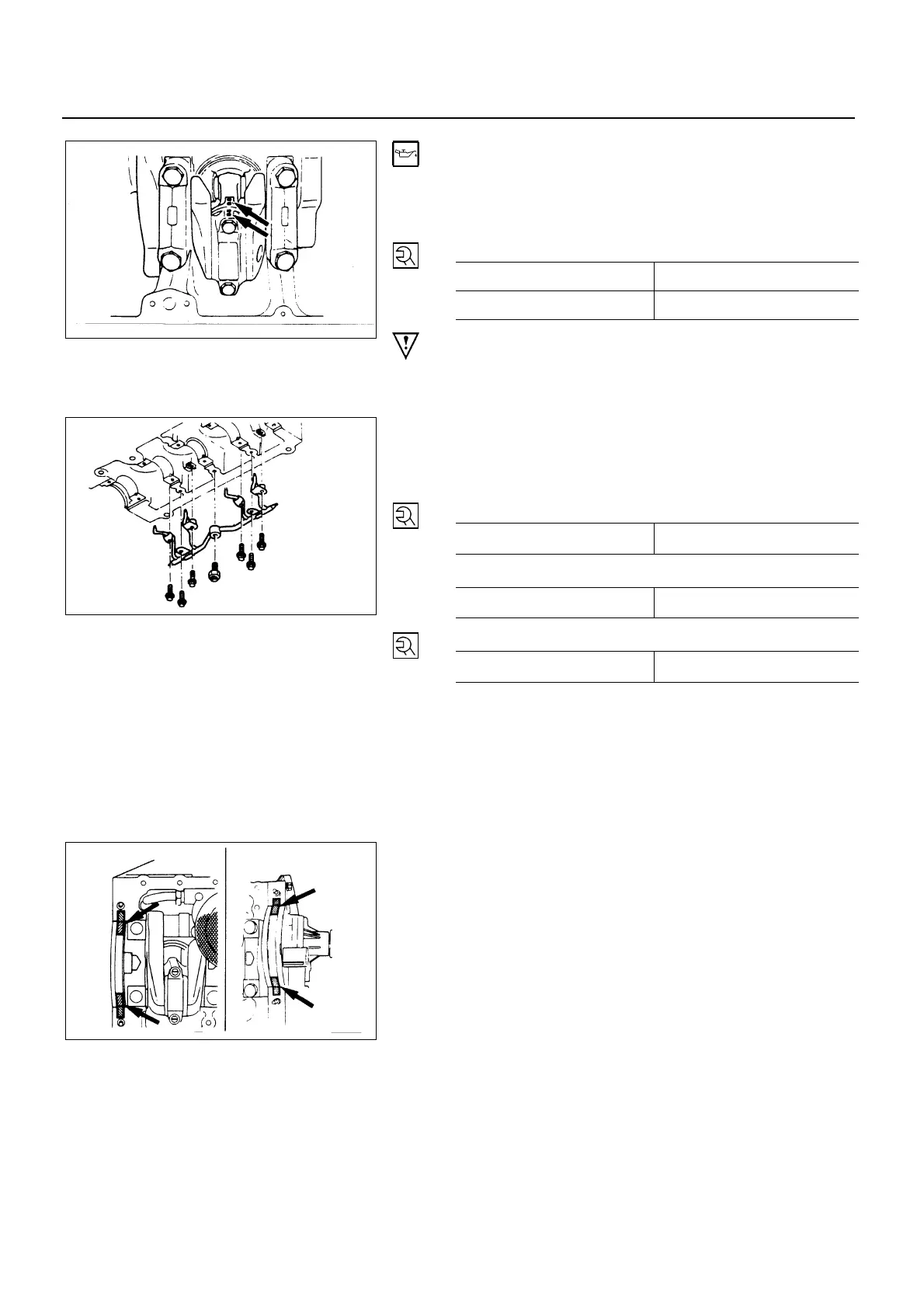

3) Apply a coat of engine oil to the threads and setting

faces of each connecting rod cap bolt.

4) Tighten the connecting rod bearing cap bolts to the

specified torque in two steps using the Angular

Tightening Method.

Connecting Rod Bearing Cap Bolt Torque N∙m (kg∙m/lb∙ft)

1st Step 2nd Step

29 (3.0/22) 45° - 60°

NOTE

Check to see that the crankshaft turns smoothly by

rotating it manually.

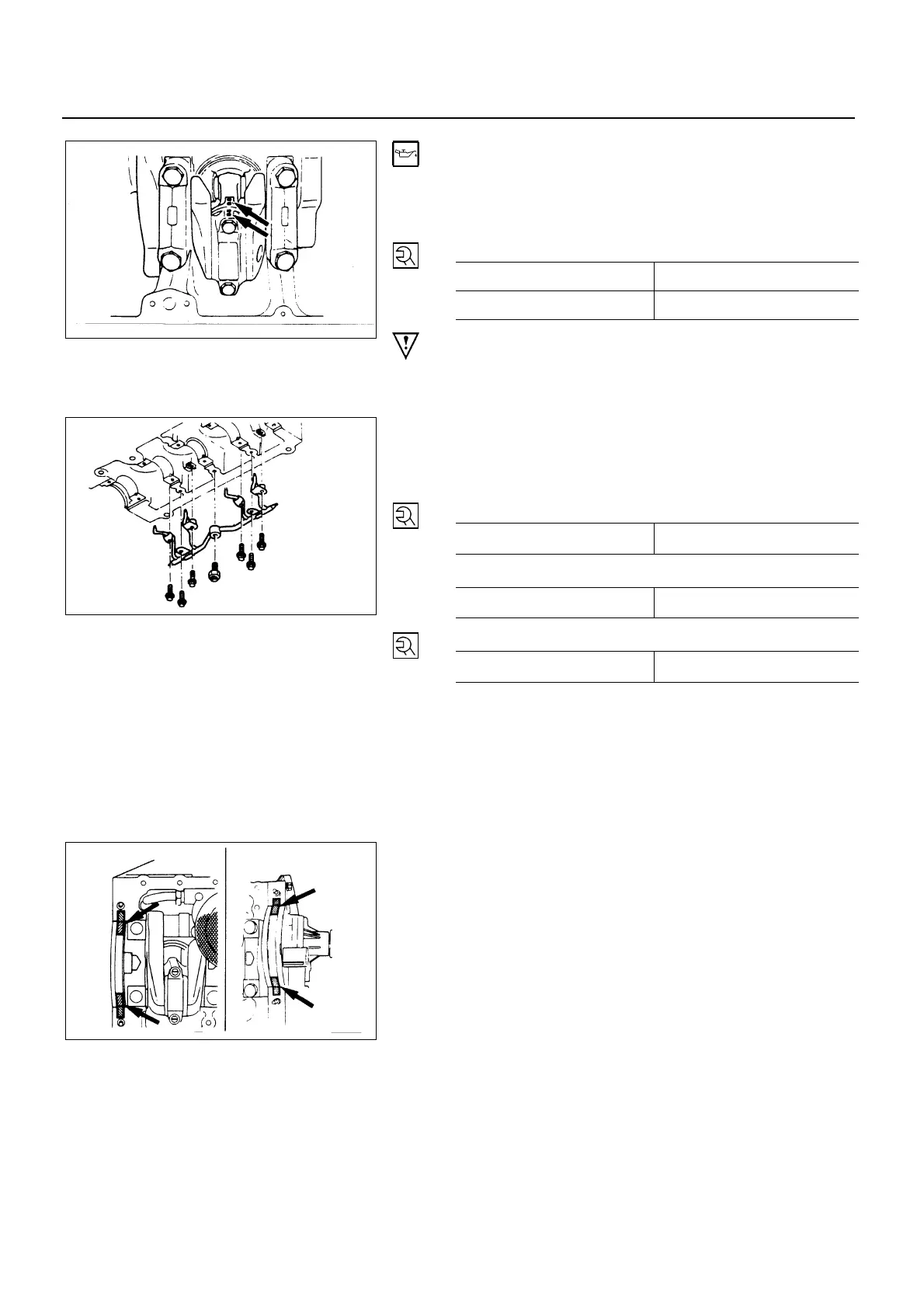

4. Piston Cooling Oil Pipe

1) Install the piston cooling oil pipe to the cylinder body.

2) Tighten the oil pipe bolts and relief valve to the

specified torque.

Oil Pipe Bolt Torque N∙m (kg∙m/lb∙ft)

!

M8x1.25

19 (1.9/14)

N∙m (kg∙m/lb∙in)

"

M6x1.00

8 (0.8/69)

Oil Pressure Regulating Valve Torque N∙m (kg∙m/lb∙ft)

#

M6x1.5

29 (3.0/22)

NOTE:

Check that there is no interference between the piston

and the oiling jet pipe by slowly rotating the

crankshaft.

3. Oil Pump Assembly

Above works refer to “OIL PUMP” Section in this manual.

2. Oil Pan Assembly

1) Apply the recommended liquid gasket or its equivalent

to the No.5 bearing cap arches, the grooves, and the

timing gear case arches at the positions shown in the

illustration.

6A1-60-1.tif

6A1-60-2.tif

Loading...

Loading...