73

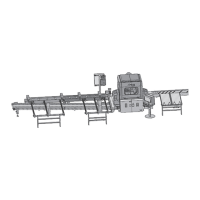

ALS 4.0 XE

PRODUCT MANUAL

EN

Appendix A – Maintenance Intervals

ALS 4.0 Machine Inspection Guide and Maintenance Log Date _______/_______/_______

EVERY SHIFT / 8 HOURS

Mon Tue Wed Thur Fri Sat Sun

Clean saw dust o the machine with a vacuum cleaner (compressed air lls the

environment with saw dust and debris and may cause a safety hazard).

Clean and ush ink jet head.

Check all light bulbs in operators control panel. Replace as required.

Check that water has drained from coalescer.

Check saw blades chipped or broken teeth.

EVERY 10 SHIFTS / 80 HOURS

Verify all calibration.

Verify All belt feeder adjustments.

Hand tighten all servo motor cables.

Inspect all cables, connections, and routing components.

Clean ink jet print sensor.

EVERY 20 SHIFTS / 160 HOURS

Inspect the refuse belts for cracks, wear, and tension.

Apply one pump of grease (NLGI Grade No. 2) to ttings.

LOCATION Total Where

L1 & L2 Pushers 8 4 on top of each bearing block

L1 & L2 Clamps 8 On the back side of the saw cabinet

T1 Bearings 4 2 on the front and 2 on the back of the head

Z1 Bearings 4 2 on the bottom and 2 on the top of the head

Outfeed Queue 6 2 bearings on each shaft under the queue

Waste Belt 4 2 on the drive roller and 2 on the idler roller

Small Parts Conveyor 4 2 on the drive roller and 2 on the idler roller

Automated Infeed (if applicable)

Infeed Wheel 4 4 on the back of the bearing block

Infeed Drive Shaft 8 Under the automated infeed rollcase

Gripper Assembly 4 1 on the back side each gripper assembly

Optional Accessories

Incline Waste Belt 4 2 on the drive roller and 2 on the idler roller

Small Parts Incline Belt 4 2 on the drive roller and 2 on the idler roller

EVERY 100 SHIFTS / 800 HOURS

Check L1/L2 belts for wear

EVERY 260 SHIFTS / 2080 HOURS

Lubricate Z1 EXLAR® actuator.

Tighten electrical connections in the main panel (Lock out / Tag Out).

Loading...

Loading...