45

ALS 4.0 XE

PRODUCT MANUAL

EN

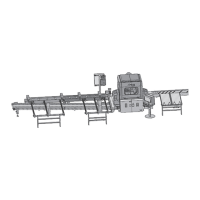

Lock nuts

Drive belt

Adjustment nut

Idler sprocket bolt

Figure 110

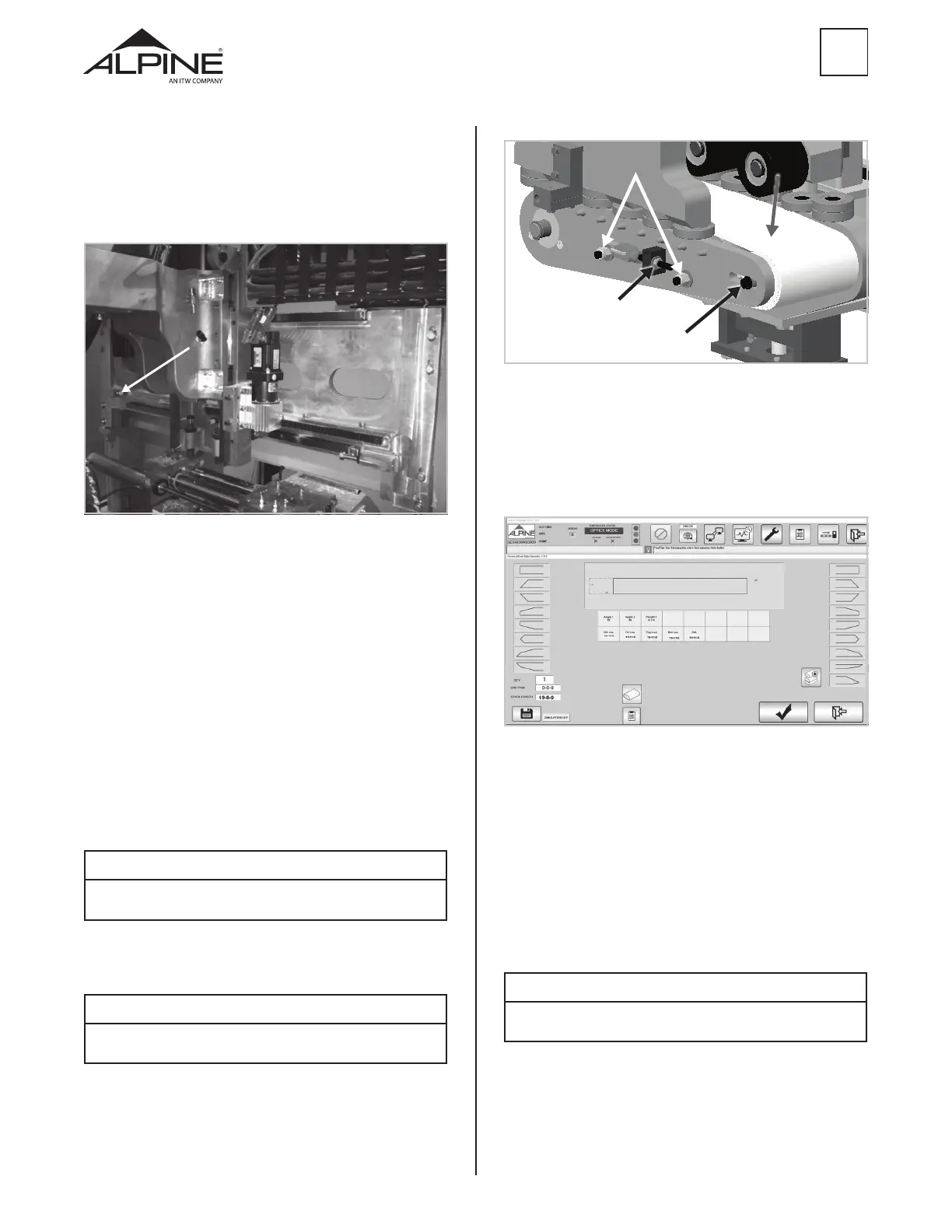

4.9 Calibrate Cut Length (L1/L2)

Step 1 – Check the L1/L2 belt tension (Section 4.8).

Step 2 – In SEMI AUTO mode, cut a board 15-11-0 and

measure and record the overall length as “Cut 1”.

Figure 111

Step 3 – Reduce the cut length by 0-1-0. Cut, measure

and record the overall length as “Cut 2”.

• If both cuts are accurate, the cut length is

calibrated. Go to the next section.

• If “Cut 1” and “Cut 2” are both long by the same

amount, or both short by the same amount

proceed to the next step.

• If the two cuts are o by dierent amounts,

contact Alpine Equipment Customer Service for

additional guidance.

NOTE

In some cases it may be necessary to repeat the cut 5-6 times to

determine the root cause of the inconsistent length.

Step 22 – The Figure below shows the hard stop for

the T-axis. If the centerline of the cut is less than 1.75”,

extend the bolt. If the centerline of the cut is greater

than 1.75”, retract the hard stop bolt. Adjust the hard

stop the distance the centerline is o.

Figure 109

Step 23 – Remove the lockout/tagout.

Step 24 – Power the machine up and follow normal

startup and homing procedures (Section 3.1). Repeat

this section until calibration is complete.

4.8 L1/L2 Belt Tension Adjustment

In order to keep the ALS 4.0 running smoothly, it may be

necessary to adjust the belt tension from time-to-time.

Step 1 – Loosen the idler sprocket bolts on both the

front and back sides of the drive assembly, then loosen

the locknuts.

Step 2 – Using a 9/16” wrench, adjust the belt tension

assembly so that the belt can only be pulled away from

the rollers by 1/4”.

NOTE

Using an appropriate torque wrench, torque the adjustment nut

to 40 in-lbs.

Step 3 – Once the belt has been properly tensioned,

tighten the idler sprocket bolts on both sides of the

drive assembly and the two lock nuts.

NOTE

The tension of the L1 & L2 belts should be checked prior to

calibrating L1 & L2.

Loading...

Loading...