EN

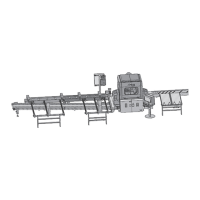

ALS 4.0 XE

Product Manual

IMPORTANT! DO NOT DESTROY!

It is the customer’s responsibility to have employees read and understand this manual.

Read instructions completely before using the equipment.

The Latest

Evolution of the

I

ndustry’s Leading

Linear Saw

The Alpine ALS 4.0 takes linear cutting to

the next level. The ALS 4.0 is designed for

production efficiency, only requiring one

sawyer for operation. The result is a reduction

in labor, a boost in production and an increase

to your bottom line.

This is not only an operation manual, but a

tool that can be utilized to gain the maximum

potential from your ALS 4.0 linear saw. Each

plant runs differently and the ALS 4.0 stands up

to the challenge—providing ultimate flexibility

in setup and operation.